A kind of layered dental titanium alloy material and its preparation method

An alloy material, titanium alloy technology, used in dental preparations, dentistry, dental prostheses, etc., can solve the problems of increased wear and tear of natural teeth, and achieve the effects of low density, high occlusal force, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

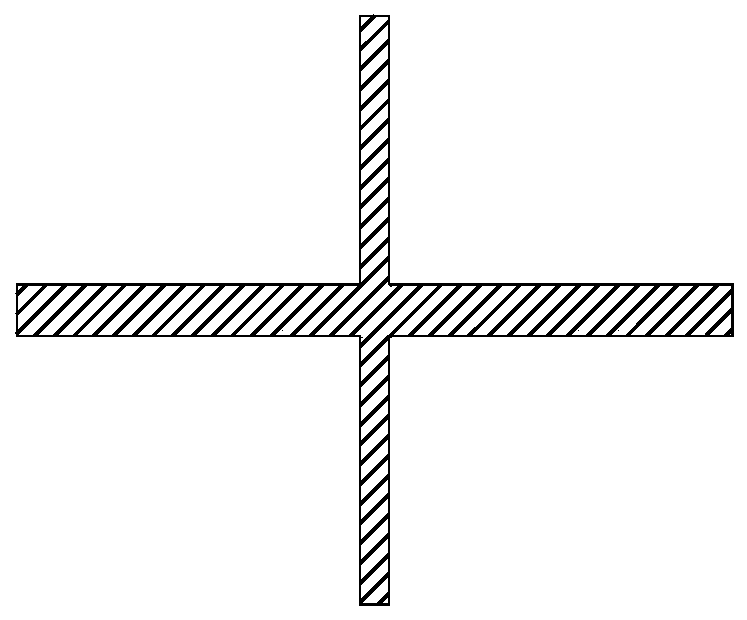

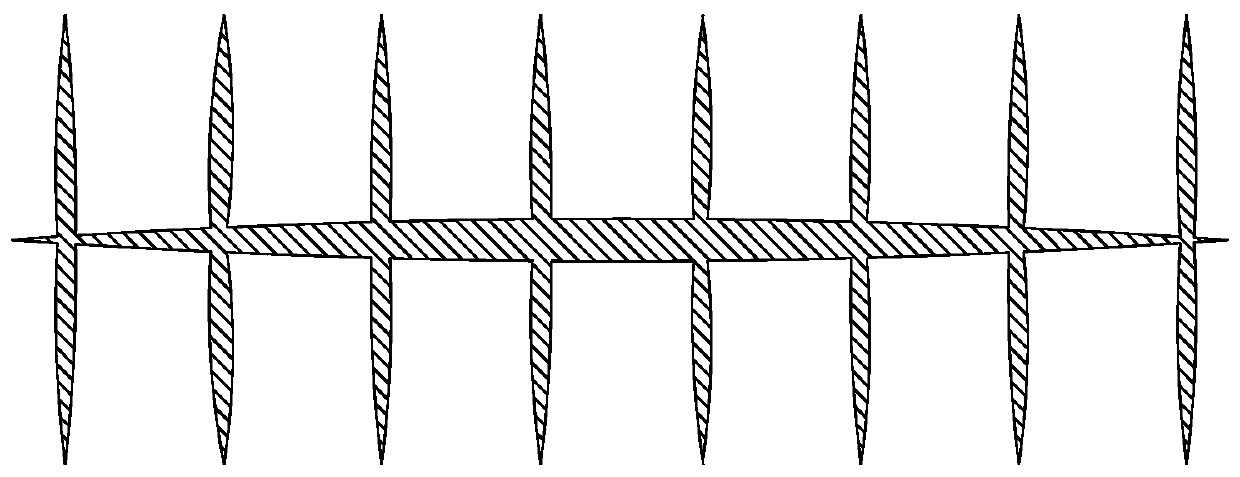

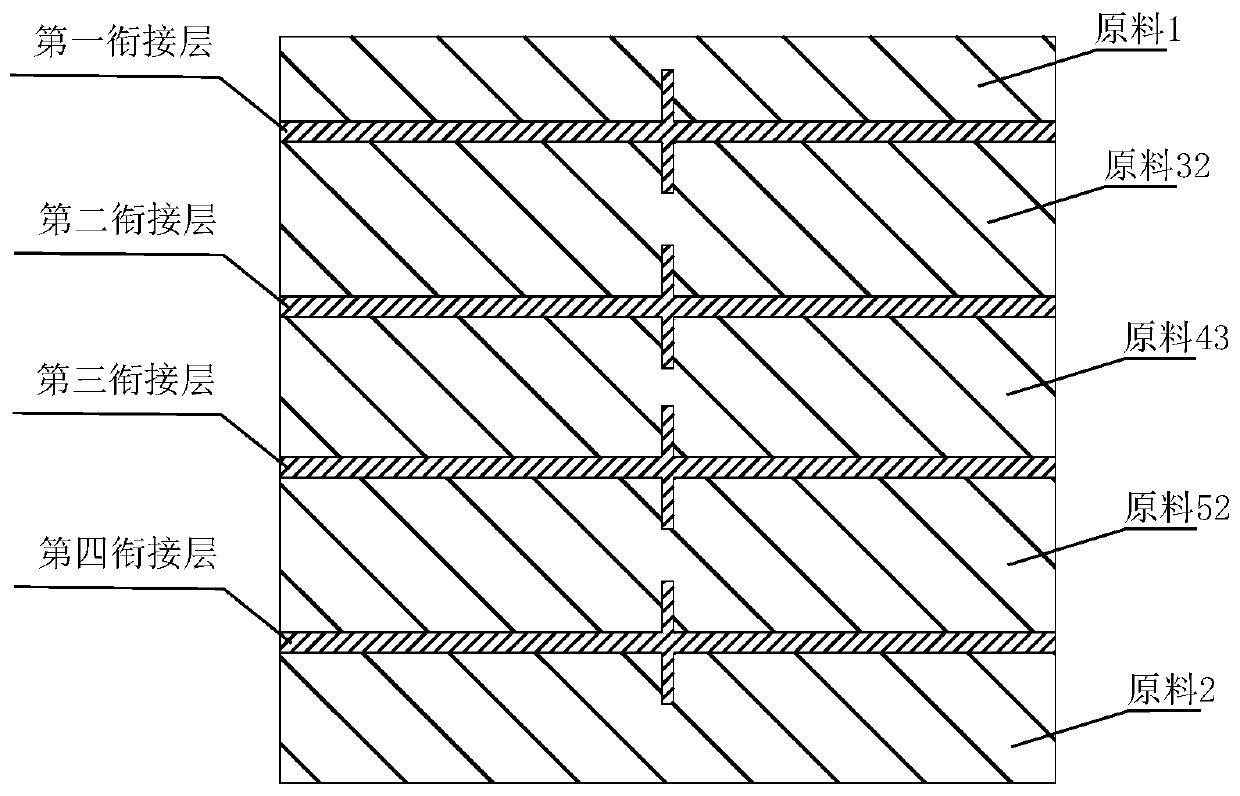

[0037] 2, the preparation method of the present invention is:

[0038] (1) Weigh 20 to 24 parts of pure titanium and 33 to 34.2 parts of titanium alloy respectively as raw materials 1 and 2; weigh 5 to 7 parts of pure titanium and 5 to 7 parts of titanium alloy (equal amounts of pure titanium and titanium alloy) ), mixed as raw material 3; weighed 5 to 7 parts of pure titanium and 7.5 to 10.5 parts of titanium alloy (by mass ratio, pure titanium: titanium alloy = 1:1.5), mixed as raw material 4; weighed 5 ~7 parts of pure titanium and 9.5~13.3 parts of titanium alloy (by mass ratio, pure titanium:titanium alloy=1:1.9) are mixed and used as raw material 5.

[0039] The specific method of mixing is as follows: Pour the desired mixed pure titanium and titanium alloy raw material powder into deionized water with at least twice the volume of the total amount of powder, or pour into other materials that do not react with pure titanium and titanium alloy, In a liquid medium that doe...

Embodiment 1

[0049] Example 1: Effect of Impurities on Properties of Layered Dental Titanium Alloy Material

[0050] 1. Prepare 20 sets of gold materials using the above formula and method, wherein the liquid medium in the mixing method is water, the drying method is low-temperature drying, and the structure of each connecting layer is a fishbone structure. In the vacuum annealing furnace, the holding temperature is 1100°C and the holding time is 4.5h.

[0051] The specific pure titanium and titanium alloys used in each group are shown in Table 1. The values in the table are percentages by mass, and elements below 0.01% are ignored. The ratio of pure titanium: titanium alloy is the mass ratio, such as 9:13, that is, in the corresponding total amount of 100 parts, pure titanium accounts for 45 parts, and titanium alloy accounts for 65 parts.

[0052] Table 1 Specific parameter list of each group

[0053]

[0054] 2. Prepare the above 20 groups of titanium alloys into 5×5cm 3 The cub...

Embodiment 2

[0058] Example 2: Influence of Index Technology on Properties of Titanium Alloy

[0059] 1. Using the above formula and method to prepare 17 groups of layered dental titanium alloy materials, the formula is selected from Group 1 of Example 1. The specific preparation process and parameters of each group are shown in Table 3; among them, pre-pressing refers to making each connecting layer first and then pressing and molding, and no pre-pressing refers to directly pressing and molding after adding each raw material in order.

[0060] Table 3 Process parameters of each group

[0061]

[0062] 2. Prepare the above 17 groups of titanium alloys into 5×5cm 3 The cube is tested for performance, and the results are shown in Table 4.

[0063] Table 4 Performance display of each group

[0064]

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com