Double-stage backheating solar driven rotary wheel drying system and running method thereof

A technology for driving the runner and drying system, which is applied in the field of drying and dehumidification, and can solve problems such as the failure of the heat pump drying device to work normally, the loss of the drying function of the heat pump drying device, and the rise in the exhaust temperature of the refrigeration compressor, so as to improve energy utilization and heat conduction Excellent performance and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

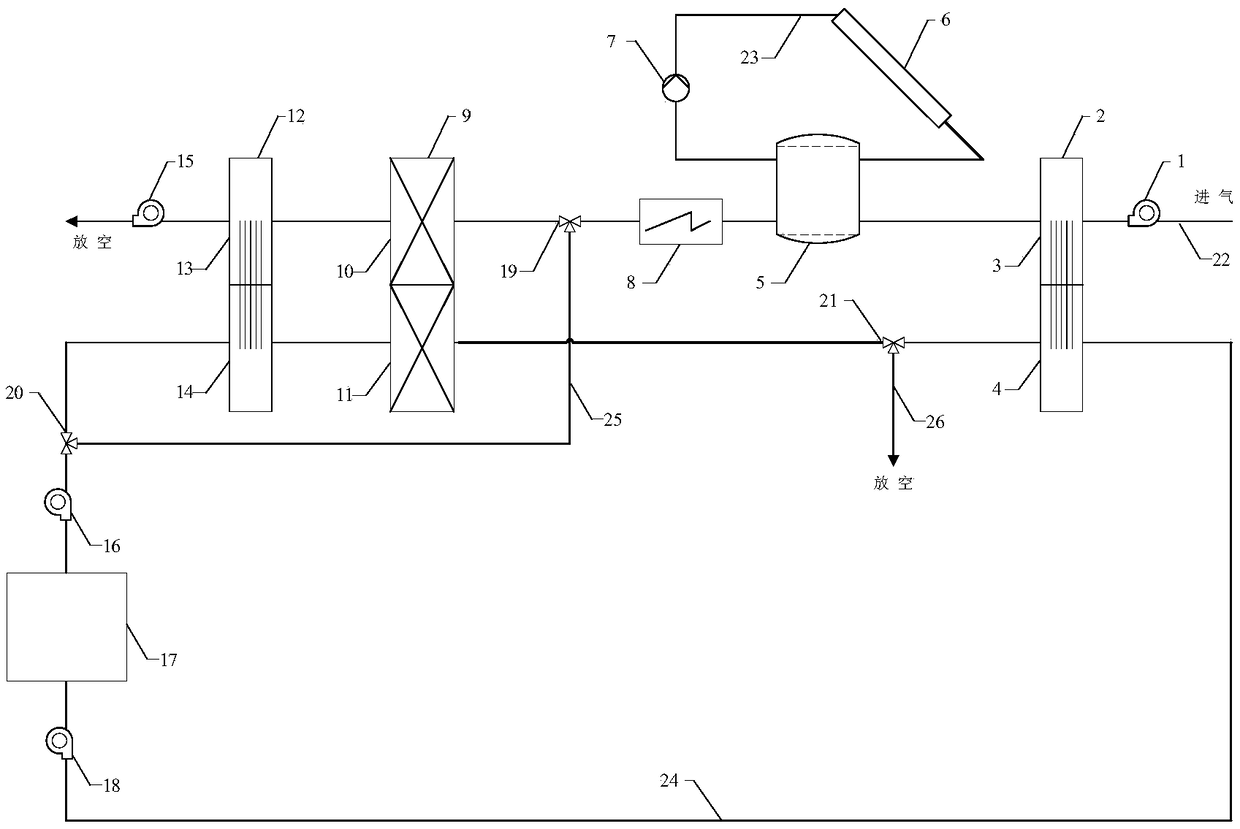

[0022] see figure 1 , a two-stage regenerative solar-driven rotary drying system, the main components of the system include a regenerative air inlet fan 1, a first heat pipe regenerator 2, a heat storage device 5, a solar collector 6, and a circulating working medium pump 7 , Auxiliary electric heater 8, runner dehumidifier 9, second heat pipe regenerator 12, regeneration air outlet fan 15, drying chamber inlet fan 16, drying chamber 17, drying chamber outlet fan 18. The whole system can be divided into solar heat storage system, regeneration air system and dehumidification air system according to the function.

[0023] For the solar heat storage system, the solar heat collector 6 , the heat storage device 5 , and the circulating working medium pump 7 are sequentially connected end to end through the circulating working medium channel 23 to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com