Production method of barium salt scallop shell powder used for soil remediation and fertility increasing

A scallop shell powder and soil remediation technology, which is applied in the field of soil remediation and soil improvement, can solve the problems of failure to achieve soil remediation and improvement effects, poor affinity of scallop shell powder, and damage to the soil microbial layer. Air permeability, the effect of enhancing soil fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

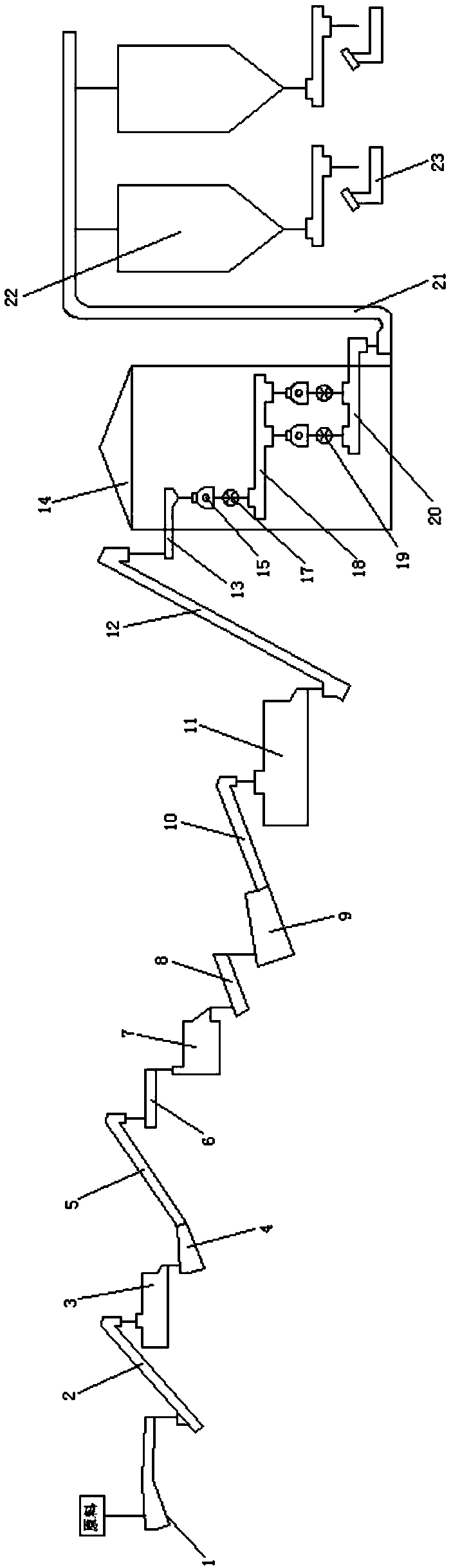

[0023] The embodiment of the present invention provides a production method of barium salt scallop shell powder used for soil restoration and fertilization, which relies on reaction equipment, and the reaction equipment includes a first measuring hopper 1, a first screw conveyor 2, Washing machine 3, second measuring bucket 4, second screw conveyor 5, first belt conveyor 6, dryer 7, second belt conveyor 8, third measuring bucket 9, third screw conveyor 10 , heating machine 11, fourth screw conveyor 12, third belt conveyor 13 and dust collection chamber 14, sixth screw conveyor 20, box conveyor 21 and product hopper 22;

[0024] The discharge port of the first measuring hopper 1 is set correspondingly to the feeding place of the first screw conveyor 2, and the discharge place of the first screw conveyor 2 is set correspondingly to the feeding port of the washing machine 3 , the discharge port of the cleaning machine 3 is set correspondingly to the feed port of the second measur...

Embodiment 2

[0034] The reaction equipment that embodiment 2 relies on is the same as embodiment 1, and embodiment 2 is the same as step 1) and step 2) of embodiment 1, the difference is that in step 3), the semi-finished scallop shell of storage is passed by the third screw The conveyor 10 transports the scallop shells to the heating machine 11, calcining and heating the scallop shells at 700° C., and the calcined and heated scallop shells are left for 6 hours to cool down to room temperature.

[0035] The content of alkali in the shell powder produced in Example 2 is 52%, the content of calcium acid is 88%, and the pH value is 8.

Embodiment 3

[0037] The reaction equipment that embodiment 3 relies on is the same as embodiment 1, and embodiment 3 is the same as step 1) and step 2) of embodiment 1, the difference is that in step 3), the semi-finished scallop shell of storage is passed by the third spiral The conveyor 10 transports the scallop shells to the heating machine 11 , calcines and heats the scallop shells at 900° C., and leaves the calcined and heated scallop shells for 12 hours to cool down to normal temperature.

[0038] The content of alkali in the shell powder produced in Example 3 is 55%, the content of calcium acidified is 95%, and the pH value is 10.

[0039] The barium salt scallop shell powder for soil remediation and fertilization prepared by the above-mentioned embodiment 1, embodiment 2 and embodiment 3 of the present invention has the following advantages:

[0040] The shell powder produced by the invention is mixed with soil, which can seal the heavy metals in the soil, neutralize the acidity an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com