Resourceful treatment system and method for sodium sulfate wastewater

A treatment system, sodium sulfate technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. The connection structure is simple, the economic benefit is improved, and the treatment effect is guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

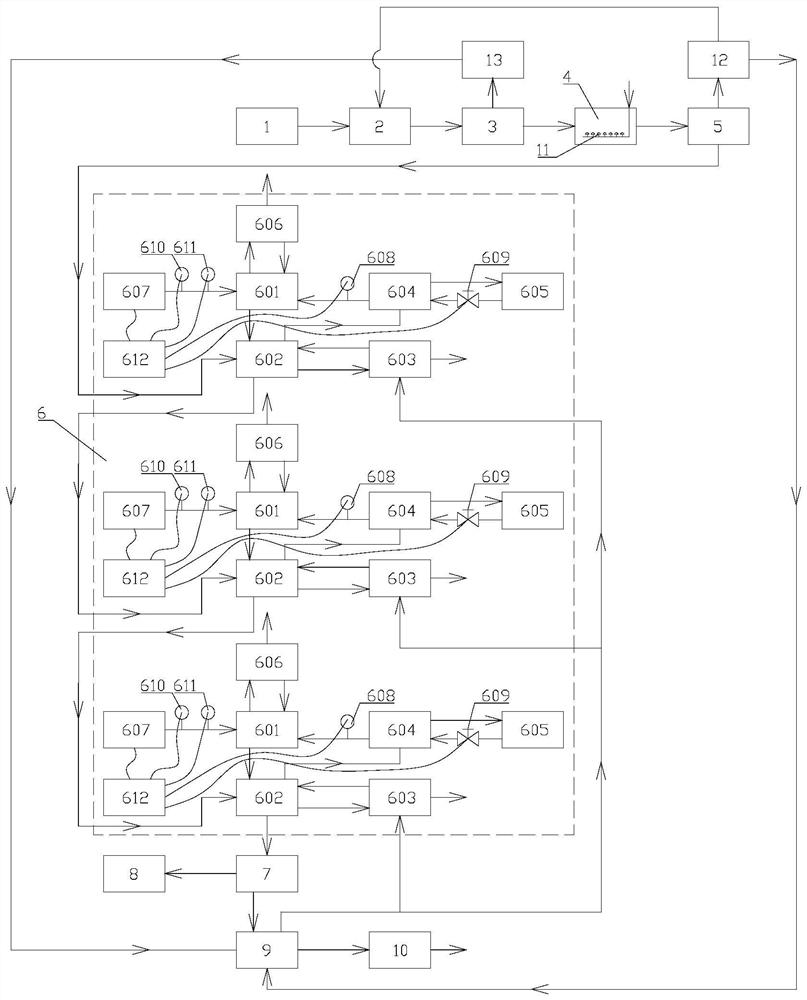

[0041] Example 1: Such as figure 1 As shown, a resource treatment system for sodium sulfate wastewater includes a collection cell 1, a first pH adjustment tank 2, a fenton reaction tank 3, a multi-function adjustment tank 4, a flat-flow sedimentation tank 5, 3 low temperature evaporation system 6 , The frozen crystalline device 7, sodium sulfate storage device 8, incinerator 9 and the exhaust gas treatment device 10; the liquid opening of the collecting pool 1 is connected to the first pH adjustment tank 2, the first pH adjustment tank 2 outlet The mouth is connected to the inlet port of the fenton reaction tank 3, and the liquid opening of the Fenton reaction tank 3 is in communication with the inlet port of the multi-function adjustment tank 4, and a aeration device 11 is provided in the multi-function adjustment pool 4. The liquid opening of the adjustment pool 4 is connected to the inlet port of the flat-flow sedimentation tank 5, and the supernatant exit of the flow sedimenta...

Embodiment 2

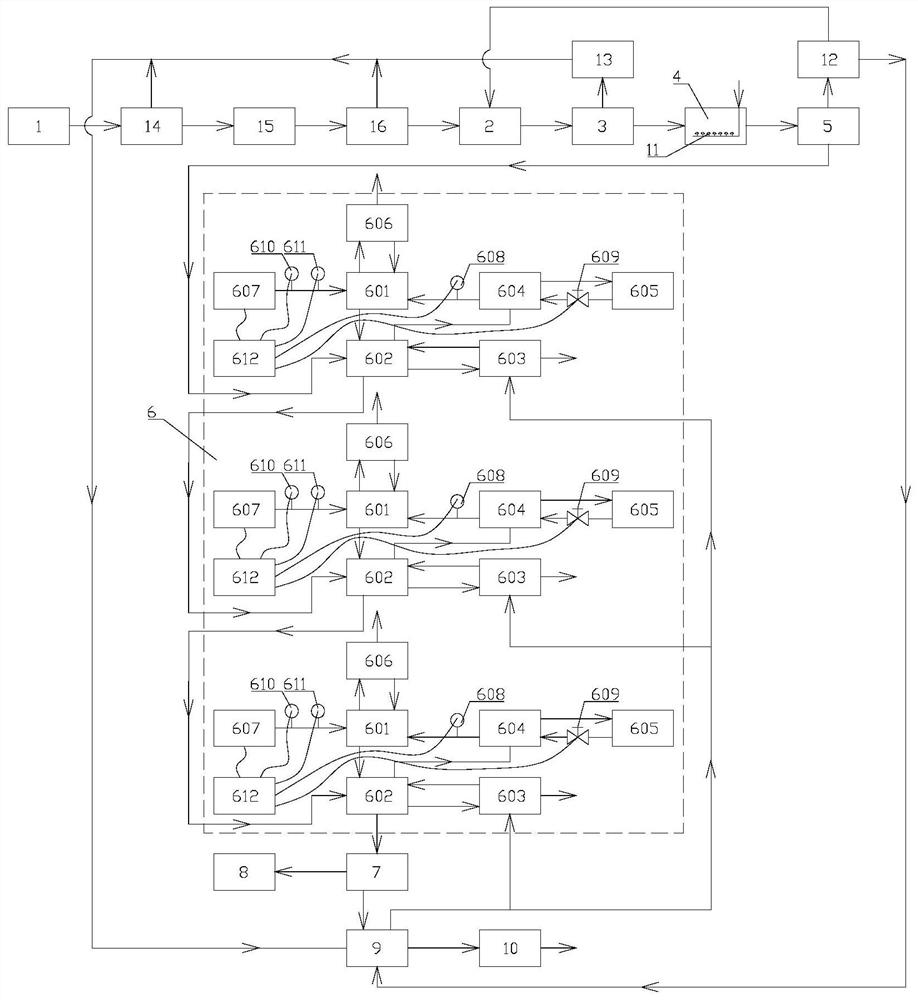

[0047] Example 2: Such as figure 2 As shown, a resource treatment system for sodium sulfate wastewater includes a collection cell 1, a first pH adjustment tank 2, a fenton reaction tank 3, a multi-function adjustment tank 4, a flat-flow sedimentation tank 5, 3 low temperature evaporation system 6 , The freezing crystal device 7, sodium sulfate storage device 8, incinerator 9, and exhaust gas treatment device 10; the overall structure is the same as in Example 1, and it is also, which further comprises iron powder oxidation devices 14, the second pH adjusting pool 15 and pre-frozen pool 16; the liquid opening of the collecting pool 1 is connected to the inlet port of the iron powder oxidation device 14; the liquid opening of the iron powder oxidative reduction device 14 is connected to the second pH adjustment pool 15. The liquid opening of the second pH adjustment pool 15 is connected to the inlet port of the pre-frozen pool 16; the liquid opening of the pre-frozen pool 16 is conn...

Embodiment 3

[0049] Example 3: The resource treatment method of sodium sulfate wastewater using the system, including the following steps:

[0050] (1) Fenton reaction: The low concentration wastewater is adjusted to 3-4 in the first pH adjustment tank 2, and then sent to the Fenton Reaction Tool 3, and then sulfate is added to the wastewater in the fenton reaction tank 3. Iron and hydrogen peroxide, iron sulfate investment amount of 4% of the amount of COD in wastewater, and the amount of hydrogen peroxide is 3% of the amount of COD in wastewater, and at a temperature of 20 ° C, the reaction is at 4 h, and the reaction is reacted Water; effective to oxidize the macromolecules in the wastewater, which effectively reduces the COD in the wastewater, neutralized the acidity of the wastewater, and then adds mixed concentrated to avoid wastewater to metal equipment and structures. Corrosion is produced to ensure the service life of the system.

[0051] (2) Aeration Induction: Send the reaction wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com