Manufacturing process for high-speed rail plate containing inorganic reinforcing fibers

A technology of inorganic reinforcement and manufacturing process, applied in the direction of manufacturing tools, ceramic molding machines, clay preparation devices, etc., can solve the problems of increased rigidity and reduced toughness, and achieve the effects of improving bonding, reducing raw material costs, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

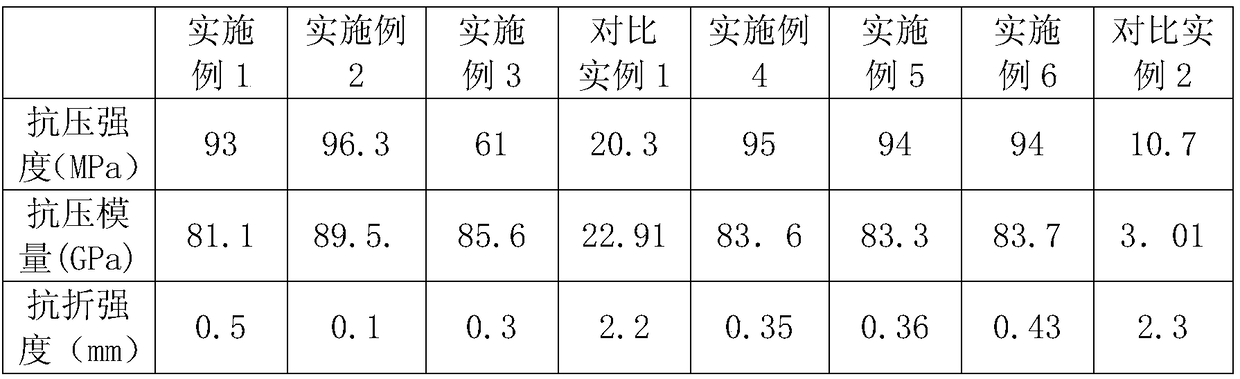

Examples

Embodiment 1

[0038] Manufacturing process of high-speed rail track slabs containing inorganic reinforced fibers:

[0039] Input the AR type untwisted glass long fiber and basalt long fiber with a mass ratio of 40:60 into the shuttle container filled with the mixed solution of EP01441-310 epoxy resin, dibutyl ester, curing agent T31, and acetone. The front-end input and the tail-end output, the AR type untwisted glass long fiber and basalt long fiber are braided into an inorganic non-metallic fiber rope with a diameter of 8mm in the twisting machine for use;

[0040] Pour EP 01441-310 epoxy resin, dibutyl ester, curing agent T31, acetone, P042.5R cement, and quartz sand with a particle size of 1.3 mm into the ring at a mass ratio of 100:8:6:6:30:60. Oxygen resin, then pour in dibutyl ester, pour in several times and stir evenly, then pour in curing agent T31 several times and stir evenly, finally pour acetone, cement, quartz sand in turn, stir evenly, fully ensure its fluidity and continuou...

Embodiment 2

[0047] Manufacturing process of high-speed rail track slabs containing inorganic reinforced fibers:

[0048] Input the AR type untwisted glass long fiber and basalt long fiber with a mass ratio of 50:50 into the shuttle container filled with the mixed solution of EP01441-310 epoxy resin, dibutyl ester, curing agent T31 and acetone. The front-end input and the tail-end output, the AR type untwisted glass long fiber and basalt long fiber are braided into an inorganic non-metallic fiber rope with a diameter of 24mm in the twisting machine for use;

[0049] Pour EP 01441-310 epoxy resin, dibutyl ester, curing agent T31, acetone, P042.5R cement, and 2.0mm quartz sand into the ring at a mass ratio of 100:13:9:11:80:110. Oxygen resin, then pour in dibutyl ester, pour in several times and stir evenly, then pour in curing agent T31 several times and stir evenly, finally pour acetone, cement, quartz sand in turn, stir evenly, fully ensure its fluidity and continuous stir;

[0050] The...

Embodiment 3

[0056] Manufacturing process of high-speed rail track slabs containing inorganic reinforced fibers:

[0057] Input the AR type untwisted glass long fiber and basalt long fiber with a mass ratio of 44:56 into the shuttle container filled with the mixed solution of EP01441-310 epoxy resin, dibutyl ester, curing agent T31 and acetone. The front-end input and the tail-end output, the AR type untwisted glass long fiber and basalt long fiber are braided into an inorganic non-metallic fiber rope with a diameter of 10mm in the twisting machine for use;

[0058] Pour EP 01441-310 epoxy resin, dibutyl ester, curing agent T31, acetone, P042.5R cement, and 1.5mm quartz sand into the ring at a mass ratio of 100:11:8:9:60:90. Oxygen resin, then pour in dibutyl ester, pour in several times and stir evenly, then pour in curing agent T31 several times and stir evenly, finally pour acetone, cement, quartz sand in turn, stir evenly, fully ensure its fluidity and continuous stir;

[0059] The imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com