Preparation method of anti-friction core-shell waterborne acrylate resin coating

A technology of water-based acrylic and ester resins, which is applied in the direction of coating, etc., can solve the problems of reduced friction, reduced compatibility of added materials and polyurethane, and large proportion of inorganic fillers, so as to reduce frictional resistance and significantly reduce drag effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

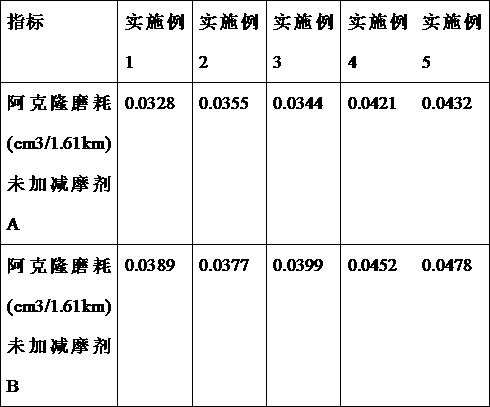

Examples

Embodiment 1

[0026] A method for preparing a friction-reducing core-shell type water-based acrylic resin coating, characterized in that: (1) Add the following raw materials in the following weight ratio to a 500ml three-necked flask: 40 g of water, 0.6 g of emulsifier (the ratio of all emulsifiers same), 0.4 g of acrylic acid, heat up to 40°C, stir for 30 minutes, add monomer A, emulsify for 30 minutes; heat up to 70°C and start to flow back water, heat up to 80°C and keep warm for 1 hour, dropwise add 0.2g of potassium persulfate (with 5g dissolved in water), the dropwise addition time continued for 1 hour, and reacted for 2 hours after the dropwise addition; then added 1 g of octamethylcyclotetrasiloxane and 1.2 g of aluminum chloride, stirred and reacted at 80° C. for 0.5 hour to obtain a core layer emulsion;

[0027] The A monomer is formed by mixing 1g of hydroxyethyl acrylate, 6g of butyl acrylate, 2g of methyl methacrylate, and 2.5g of ethyl acrylate;

[0028] (2) Add B monomer and ...

Embodiment 2

[0036] A method for preparing a friction-reducing core-shell water-based acrylic resin coating, which is characterized in that: (1) Add the following raw materials in the following weight ratio to a 500ml three-necked flask: 60 g of water, 1.4 g of emulsifier, 2.0 g of acrylic acid, Raise the temperature to 55°C, stir for 30 minutes, add A monomer, and emulsify for 60 minutes; when the temperature rises to 70°C, start to flow back water, heat up to 80°C and keep warm for 1 hour, add 0.5g of ammonium persulfate (dissolved in 5g of water), dropwise Continue for 2 hours, and react for 2 hours after the dropwise addition; then add 2 g of γ-chloropropyltriethoxysilane and 1.2 g of aluminum chloride, stir and react at 80° C. for 0.5 hours to obtain a core layer emulsion;

[0037] The A monomer is formed by mixing 2 g of hydroxyethyl acrylate, 8 g of butyl acrylate, 6 g of methyl methacrylate, and 3.5 g of ethyl acrylate;

[0038] (2) Add monomer B and 0.4g of ammonium persulfate (di...

Embodiment 3

[0046] A method for preparing a friction-reducing core-shell water-based acrylic resin coating, characterized in that: (1) Add the following raw materials in the following weight proportions to a 500ml three-necked flask: 50 g of water, 1.0 g of emulsifier, 1.2 g of acrylic acid, Raise the temperature to 48°C, stir for 30 minutes, add A monomer, and emulsify for 45 minutes; when the temperature rises to 70°C, start to flow back water, after raising the temperature to 80°C, keep warm for 1 hour, and dropwise add azobisisobutylamidine hydrochloride (AIBA, V- 50 initiator) 0.35g (dissolved with 5g water), the time of dropping continued for 1.5h, and after the dropwise addition, reacted for 2h; then added 1.5 g of 5,7-dihydroxy-4'-methoxy isoflavone and aluminum chloride 1.2g, stirred and reacted at 80°C for 0.5h to obtain a core layer emulsion;

[0047] The A monomer is formed by mixing 1.5 g of hydroxyethyl acrylate, 7 g of butyl acrylate, 4 g of methyl methacrylate, and 3 g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com