Preparation method of antibacterial coating for inner walls of recycled water storage tanks

An antibacterial coating and water recycling technology, applied in coatings, antifouling/underwater coatings, devices for coating liquids on surfaces, etc. Bacteriostatic agent leakage and other problems, to achieve the effect of low cost, strong self-cleaning ability, and enhanced anti-fouling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

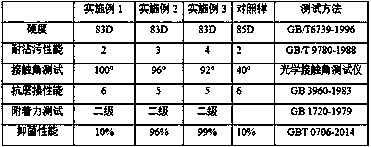

Examples

Embodiment 1

[0029] A method for preparing an antibacterial coating on the inner wall of a recovered water storage tank, the base material selected is a stainless steel substrate, specifically comprising the following steps:

[0030] 1. Pretreatment: The substrate is ultrasonicated for 5 minutes at room temperature with a surface eluent. The composition of the surface eluent is: triethanolamine (12%), alkylphenol polyoxyethylene ether (6%), sodium bicarbonate (1.5 %), ethanol (8.5%), pure water (72%). Then rinse the surface with ultra-pure water, and then soak it in strong alkaline electrolytic water for 1min. The components of the strong alkaline solution are: NaOH (0.5%), sodium bicarbonate (1%), sodium phosphate (2%), ethanol (6.5%), pure water (90%). Take it out and rinse the surface with ultrapure water, then soak it in 40°C ethanol solution for 5 minutes, finally rinse it with ultrapure water, put it in an oven at 70°C to dry for 4 hours, take it out and seal it for storage.

[003...

Embodiment 2

[0034] A method for preparing an antibacterial coating on the inner wall of a recovered water storage tank, the base material selected is a stainless steel substrate, specifically comprising the following steps:

[0035] 1. Pretreatment: The substrate is ultrasonicated for 5 minutes at room temperature with a surface eluent. The composition of the surface eluent is: triethanolamine (12%), alkylphenol polyoxyethylene ether (6%), sodium bicarbonate (1.5 %), ethanol (8.5%), pure water (72%). Then rinse the surface with ultra-pure water, and then soak it in strong alkaline electrolytic water for 1min. The components of the strong alkaline solution are: NaOH (0.5%), sodium bicarbonate (1%), sodium phosphate (2%), ethanol (6.5%) and pure water (90%) are taken out and rinsed with ultrapure water, then soaked in 40°C ethanol solution for 5 minutes, finally rinsed with ultrapure water, dried in an oven at 70°C for 4 hours, taken out and sealed for storage .

[0036] 2. Preparation of...

Embodiment 3

[0039] A method for preparing an antibacterial coating on the inner wall of a recovered water storage tank, the base material selected is a stainless steel substrate, specifically comprising the following steps:

[0040] 1. Pretreatment: The substrate is ultrasonicated for 5 minutes at room temperature with a surface eluent. The composition of the surface eluent is: triethanolamine (12%), alkylphenol polyoxyethylene ether (6%), sodium bicarbonate (1.5 %), ethanol (8.5%), pure water (72%). Then rinse the surface with ultra-pure water, and then soak it in strong alkaline electrolytic water for 1min. The components of the strong alkaline solution are: NaOH (0.5%), sodium bicarbonate (1%), sodium phosphate (2%), ethanol (6.5%) and pure water (90%) are taken out and rinsed with ultrapure water, then soaked in 40°C ethanol solution for 5 minutes, finally rinsed with ultrapure water, dried in an oven at 70°C for 4 hours, taken out and sealed for storage .

[0041]2. Preparation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com