Net-like structure

A structure and mesh technology, used in mattresses, other seating furniture, applications, etc., can solve the problems of poor durability, low hardness, and high content of hard components, and achieve the effect of excellent durability and low resilience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

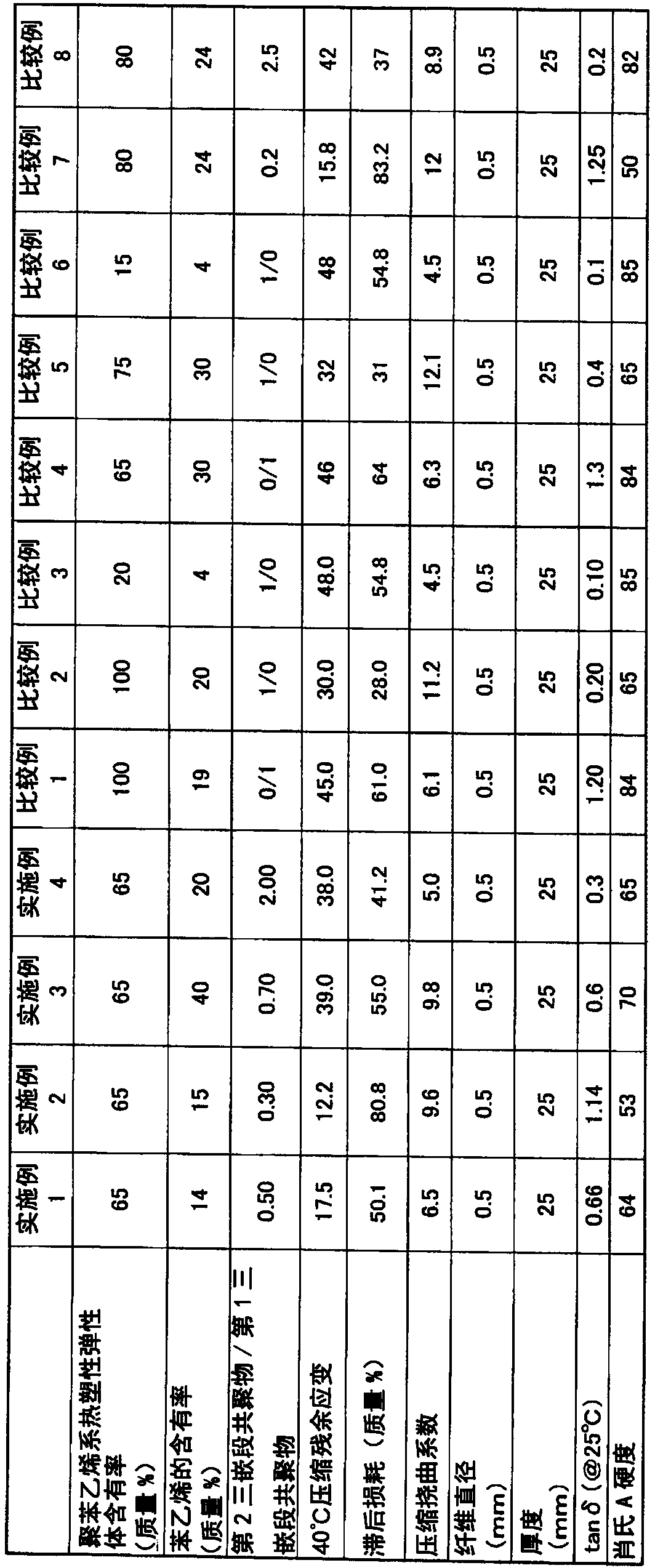

[0060] Hereinafter, although an Example is shown and this invention is demonstrated concretely, this invention is not limited to these. The measurement and evaluation of the characteristic value in an Example were performed as follows. In addition, the size of a sample is based on the size described below, but when the sample is insufficient, it measures using the sample size of a possible size.

[0061] (1) Existence and content of polystyrene-based thermoplastic elastomer

[0062] The presence of the polystyrene-based thermoplastic elastomer was confirmed by infrared absorption spectroscopy, and the content was measured by GPC. As the measurement device, a gel permeation chromatograph "L-7000 series" manufactured by Hitachi, Ltd. was used, TSKgel G4000HXL×2 columns (manufactured by Tosoh Corporation) were used as a column, and tetrahydrofuran was used as a solvent. Measurement was performed under the conditions of flow rate: 1 ml / min, concentration: 20 mg / 10 ml (sample / tet...

Synthetic example 1

[0091] In a 5-liter autoclave, 1,800 g of cyclohexane, 30 g of styrene monomer, and 0.32 g of n-butyllithium were added, and polymerized at 60°C for 1 hour, and then, 162 g of isoprene monomer was added, and polymerized at 60°C for 1 hour . Finally, 30 g of a styrene monomer was added, and it polymerized at 60 degreeC for 1 hour. The same amount of methanol was added to this active polymer solution to deactivate it, and then it was precipitated in a large amount of methanol to recover the polystyrene-based thermoplastic elastomer (S-1) containing isoprene. The obtained isoprene-containing polystyrene-based thermoplastic elastomer (S-1) had a styrene content of 30% by mass and a weight average molecular weight of 170,000. Here, "polystyrene-based thermoplastic elastomer (S-1) containing isoprene" means a 1st triblock copolymer.

Synthetic example 2

[0093] In a 5-liter autoclave, add 1,800 g of cyclohexane, 67.5 g of styrene monomer and 0.5 g of n-butyllithium, and polymerize at 60° C. for 1 hour, then add 315 g of 1,3-butadiene monomer, and °C for 1 hour. Finally, 67.5 g of styrene monomer was added, and it polymerized at 60 degreeC for 1 hour. The same amount of methanol was added to this active polymer solution to deactivate it, and then it was precipitated in a large amount of methanol to recover the polystyrene-based thermoplastic elastomer (S-2) containing butadiene. The obtained butadiene-containing polystyrene-based thermoplastic elastomer (S-2) had a styrene content of 30% by mass and a weight average molecular weight of 270,000. Here, the "polystyrene-based thermoplastic elastomer (S-2) containing butadiene" means the second triblock copolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile modulus | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com