Vibronic sensor

An electronic vibration and sensor technology, applied in the direction of instruments, flow characteristics, scientific instruments, etc., can solve the problems that can no longer ensure accurate measurement of density, and achieve the effect of simple measurement principle and speed increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

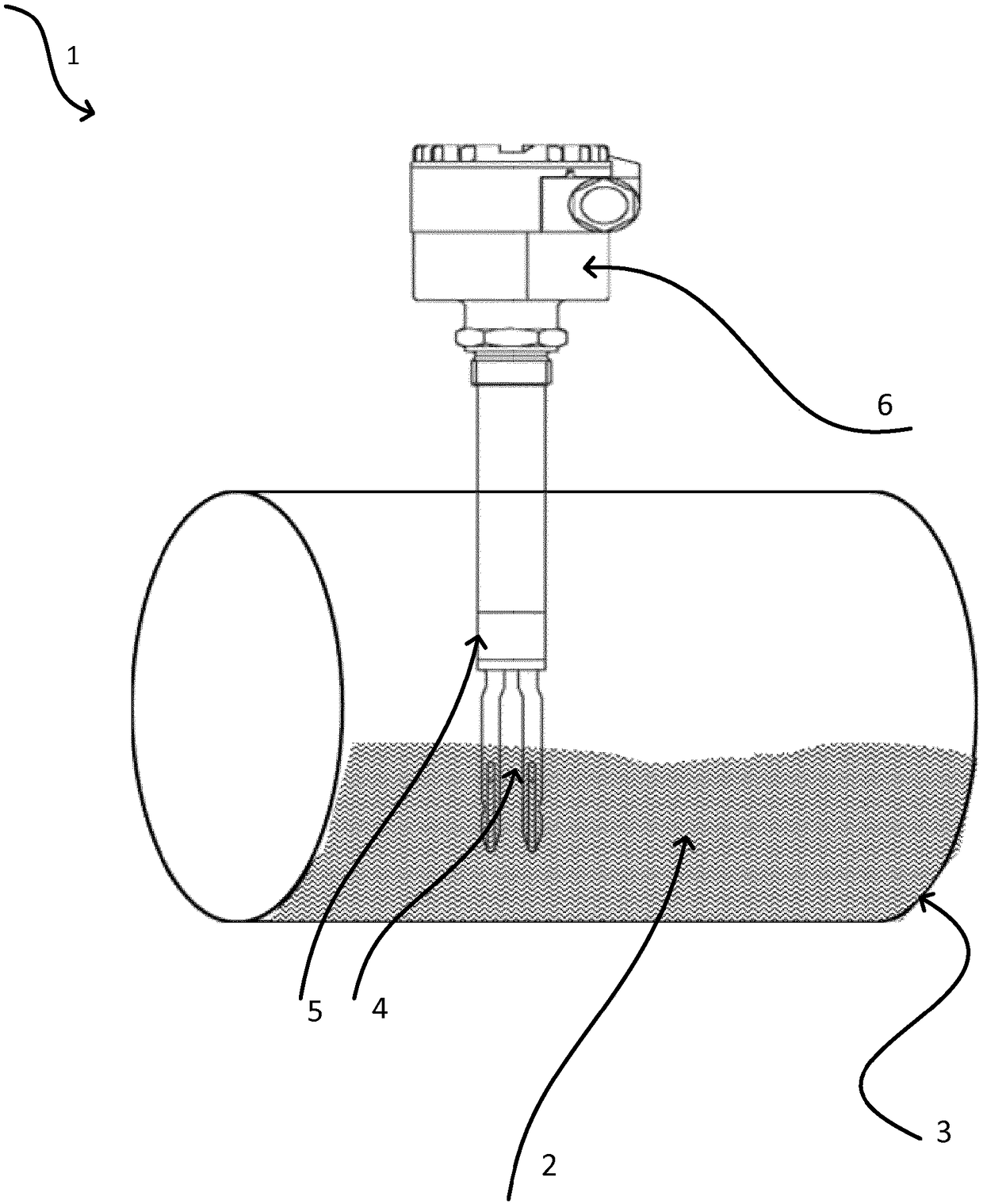

[0051] figure 1 An electronic vibration sensor 1 is shown comprising an oscillatable unit 4 in the form of an oscillating fork which extends partially into a medium 2 located in a container 3 . The oscillatable unit is excited by an exciter / receiver unit 5, eg a piezoelectric stack or a bimorph driver, to perform mechanical oscillations. However, it should be understood that other embodiments of the electronic vibration sensor are also within the scope of the present invention. An electronic unit 6 is also provided, via which signal recording, evaluation and / or feedback takes place.

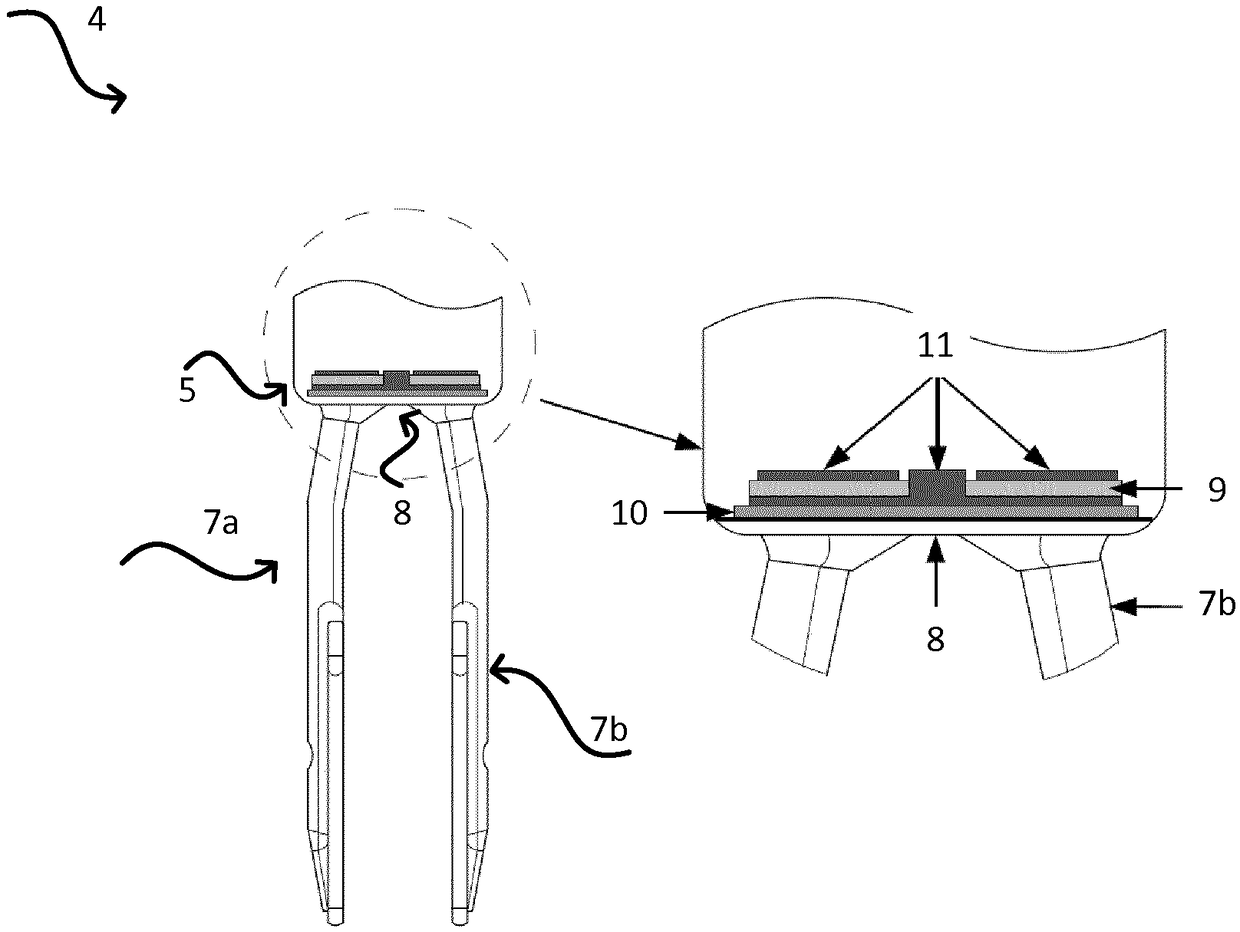

[0052] figure 2 An oscillatable unit 4 in the form of an oscillating fork is shown, such as integrated into, for example, an electronic vibration sensor sold by the applicant under the trademark LIQUIPHANT. The oscillating fork 4 comprises two oscillating tines 7 a and 7 b connected to a membrane 8 . In order for the oscillating teeth 7 a , 7 b to perform a mechanical oscillation, a force is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com