Resin composition for polarizer protective film, polarizer protective film

A technology of resin composition and protective film, applied in the direction of polarizing elements, etc., can solve the problems of high water absorption, non-proposed polarizer protective film, dimensional deformation, etc., and achieve the effect of excellent appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

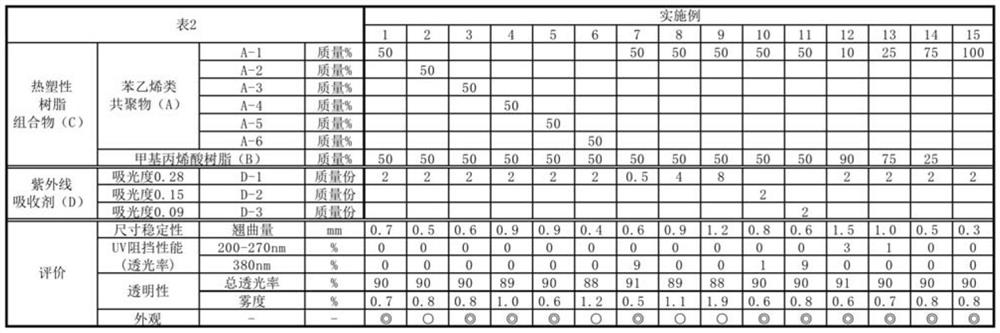

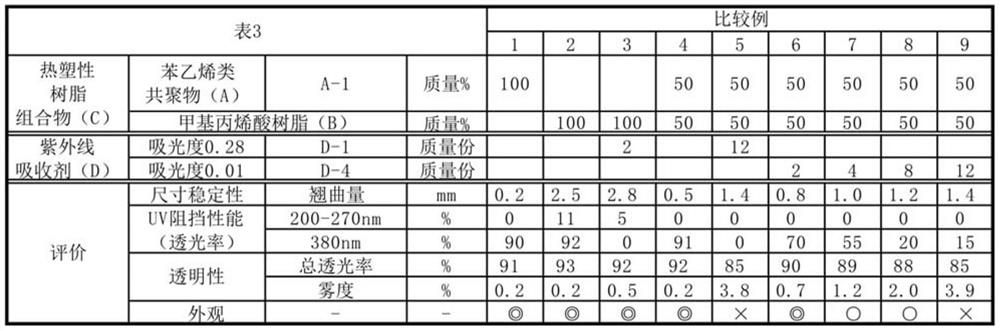

Examples

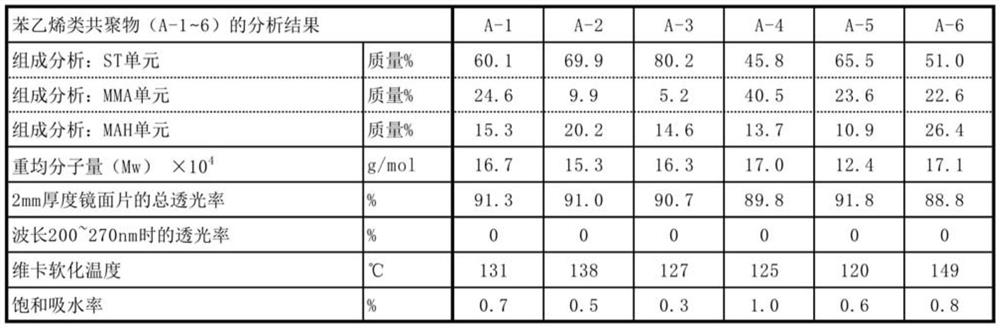

manufacture example

[0071] Prepare in advance a 20% maleic anhydride solution dissolved in methyl isobutyl ketone so that the concentration of maleic anhydride becomes 20% by mass, and tert-butylperoxy-2-ethylhexanoate becomes 2% by mass A 2% solution of tert-butylperoxy-2-ethylhexanoate obtained in methyl isobutyl ketone was diluted for polymerization. Drop into 20% maleic anhydride solution 2.6kg, styrene 26kg, methyl methacrylate 11.4kg, tert-dodecyl mercaptan 32g, methyl isobutyl ketone 2kg in the 120-liter autoclave with stirrer, will After replacing the gaseous phase with nitrogen, the temperature was raised to 87° C. over 40 minutes while stirring. After heating up, 20% maleic anhydride solution was continuously added at a batch rate of 1.5kg / hour and 2% tert-butyl peroxide was continuously added at a batch rate of 375g / hour for 8 hours while maintaining 87°C. – 2-Ethylhexanoate solution. Thereafter, the batchwise addition of the 2% tert-butylperoxy-2-ethylhexanoate solution was stopped,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com