Single-tower three-region desulfuration and white smoke-removal integrated device and method

The technology of a water retaining device and an absorption tower is applied in the field of flue gas purification, which can solve the problems of large land occupation, difficult implementation, and failure of the desulfurization system, and achieve the effects of improving heat transfer efficiency, low investment and operation cost, and reduced floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with embodiment, but protection scope of the present invention is not limited to this:

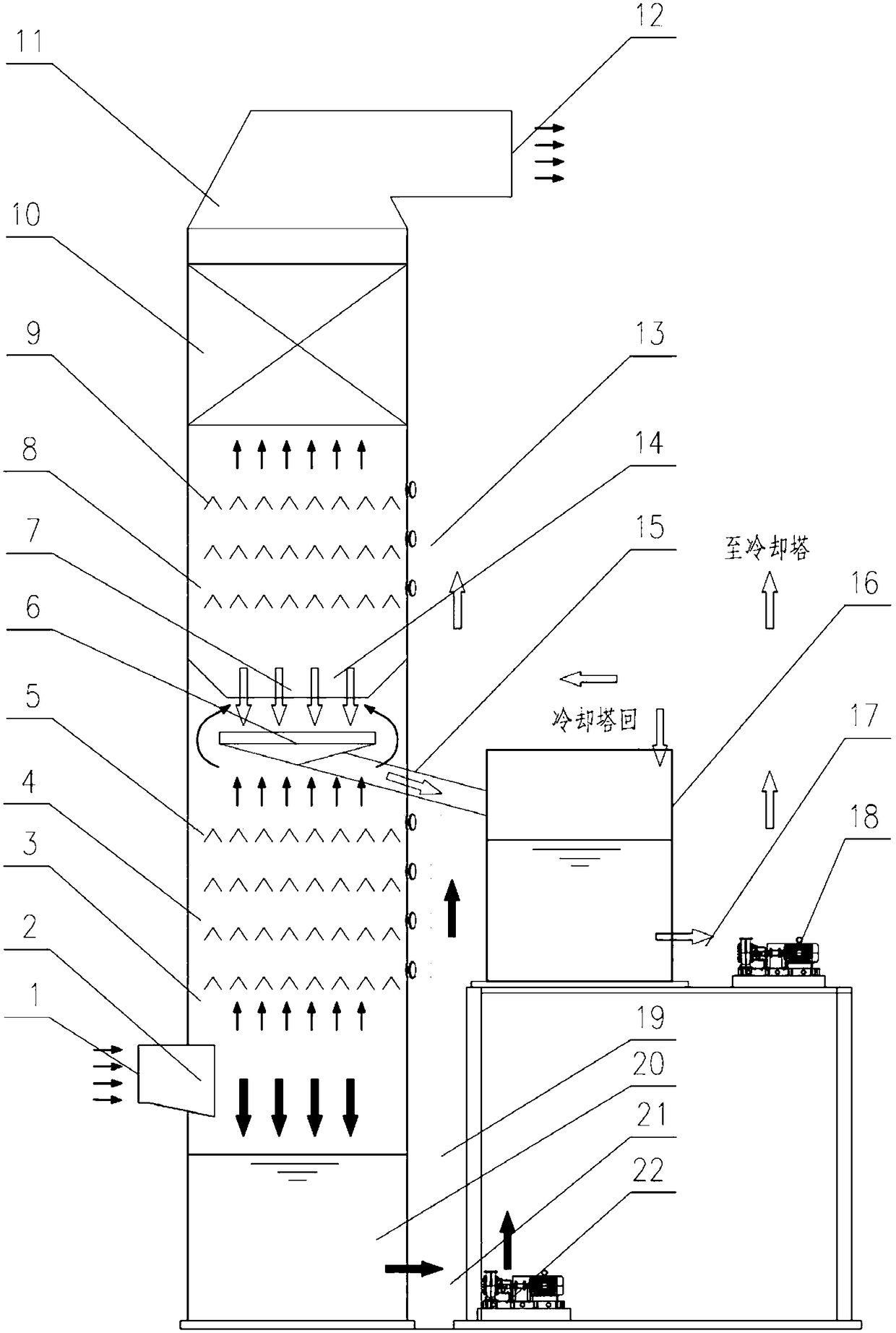

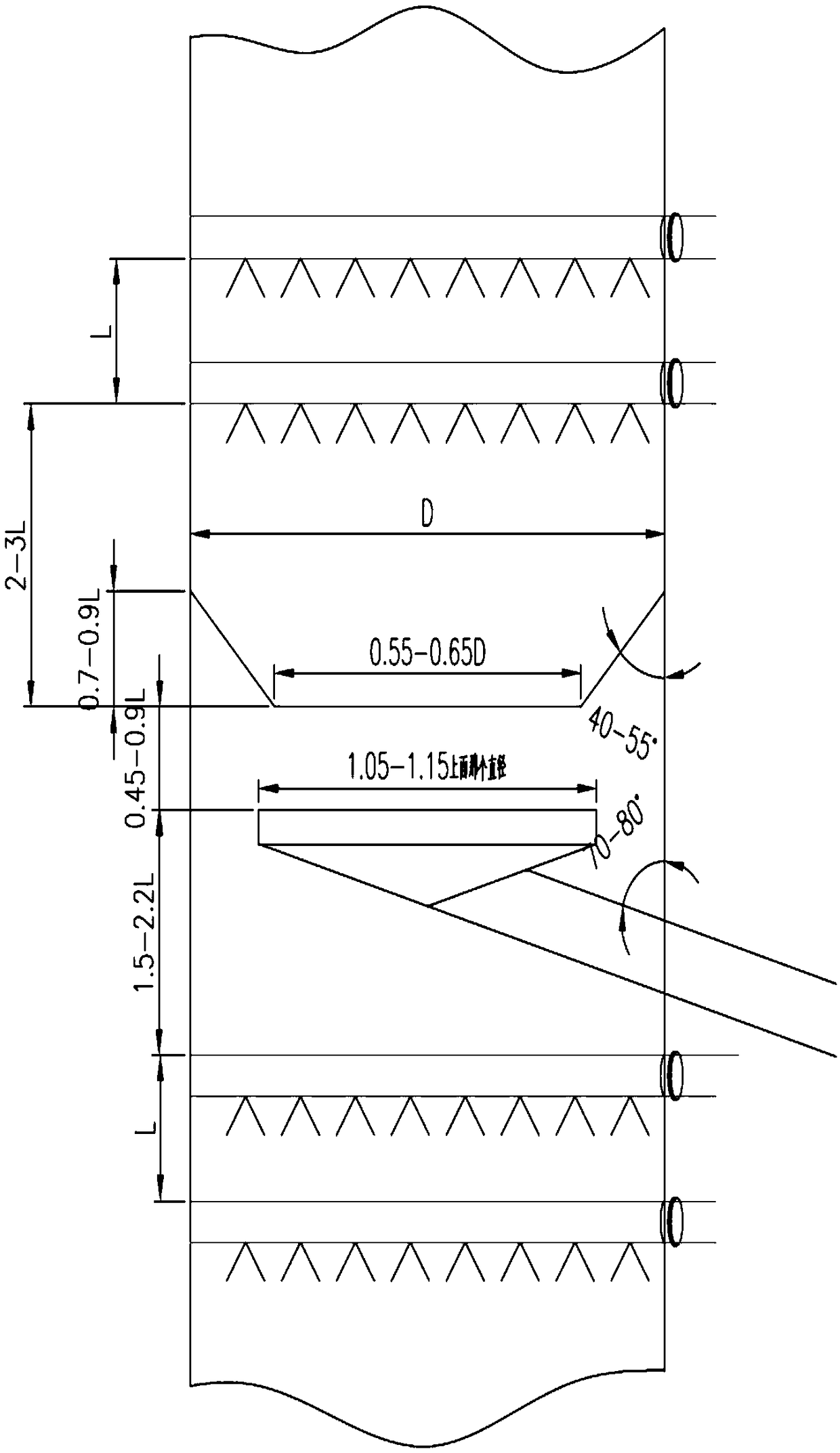

[0036] Such as figure 1 Or 2, a single-tower three-zone desulfurization and dewhitening integrated device, the device includes an absorption tower inlet flue (2), a desulfurization and dewhitening integrated tower (3), an absorption tower outlet flue (11) and a tower bottom The slurry tank (20), above the entrance of the absorption tower, is provided with a multi-stage slurry spray layer (4), a partition device (14) in the tower, a multi-stage cooling water spray layer (8) and a dust and mist removal device (10), the slurry spray layer (4) and the cooling water spray layer (8) are respectively provided with the slurry spray layer nozzle (5) and the cooling water spray layer nozzle (9), and the cooling water spray layer ( 8) The condensate is collected by the partition device (14) in the tower and then returned to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com