Large depth-of-fusion and large depth-to-width ratio perforated plasma arc welding device and welding method

A welding device and plasma arc technology, applied in the field of plasma welding, can solve problems such as molten pool collapse, small depth and width, and limited workpiece thickness, and achieve the effects of good stiffness, strong compression, and strong restraint of eddy currents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

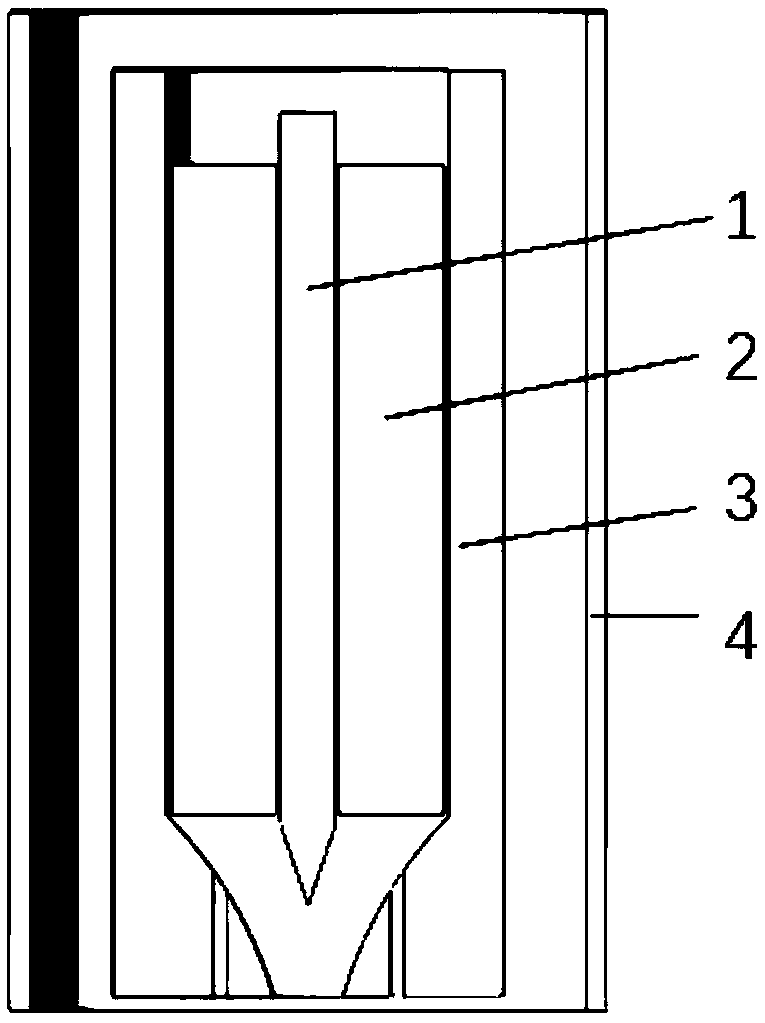

[0037] A perforated plasma arc welding device with large penetration depth and large depth-to-width ratio, including a welding torch. There is a gas hood, and the protective gas is passed between the water-cooled copper nozzle and the gas hood.

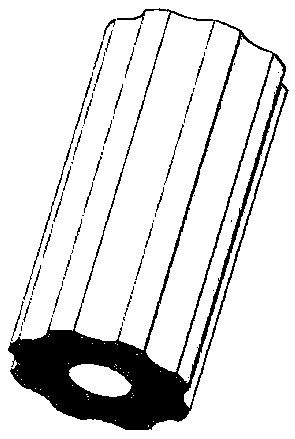

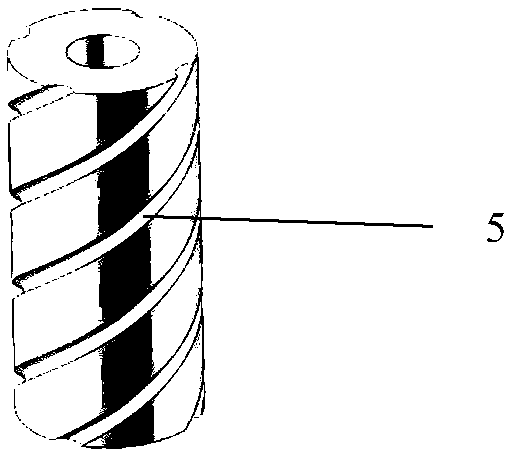

[0038] The outer surface of the porcelain sleeve is provided with a spiral guide groove, such as image 3 As shown, the ionized gas is passed between the porcelain sleeve and the water-cooled copper nozzle, and the arc is ejected from the end of the water-cooled copper nozzle after ionization. The ionized gas passes between the inner wall of the water-cooled copper nozzle and the diversion groove, and the ionized gas flows out from the outlet of the water-cooled copper nozzle. , the ion gas forms a vortex in the lower cavity of the water-cooled copper nozzle; the volume of the lower cavity of the water-cooled copper nozzle is smaller than that of the upper cavity, and the inner wall of the lower cavity is a streamlined inner wall.

...

Embodiment 2

[0041] A perforated plasma arc welding device with large penetration depth and large aspect ratio, its structure is as described in Example 1, the difference is that the diversion groove on the outer surface of the porcelain sleeve is an arc-shaped groove, and the arc size of the diversion groove is R1.4, the unit is mm, the number of diversion grooves is 4, and the number of turns of diversion grooves is 3 turns.

[0042] The ion gas is restricted by the diversion groove and the inner wall of the nozzle, and the restriction of the ceramic sleeve is not released until it is close to the tip of the tungsten electrode. The free path of the ion gas is short and its directivity is strong, which is beneficial to the increase of arc stiffness. Compared with the direct blowing air flow, the gas in the vortex converges spirally towards the center, and its center is a low-pressure area, which is conducive to the stability of the arc column at the center of the nozzle hole, which not onl...

Embodiment 3

[0044] A perforated plasma arc welding device with large penetration depth and large aspect ratio, its structure is as described in Embodiment 2, the difference is that the arc size of the diversion groove is R0.5, the unit is mm, and the number of diversion grooves 3, and the number of turns of the diversion groove is 1 turn.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com