Preparation method of Ag-Mg alloy type MgO film for high-energy particle bombardment

A high-energy particle, alloy-type technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problem of insufficient Mg oxidation of MgO film layer, achieve increased thickness, improve secondary emission coefficient, The effect of avoiding film contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and examples.

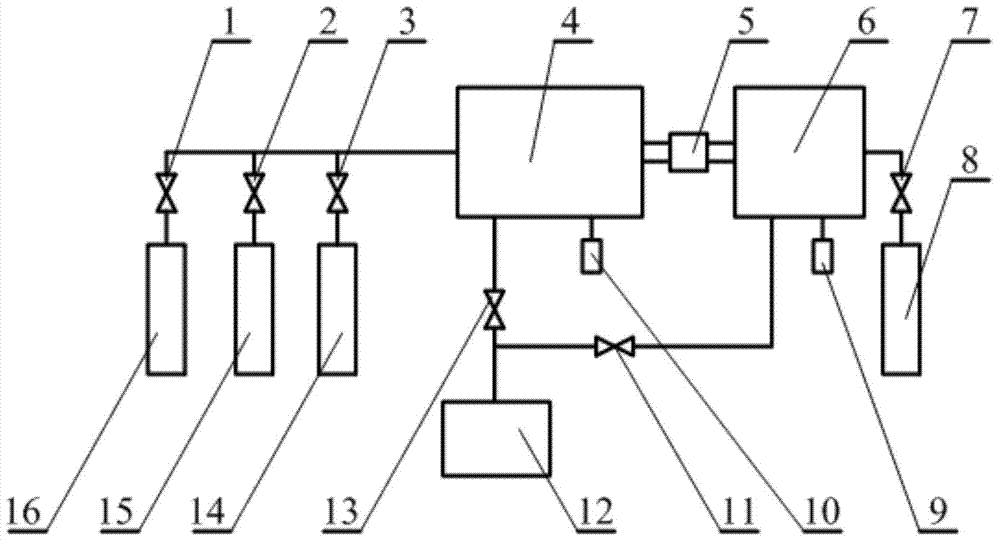

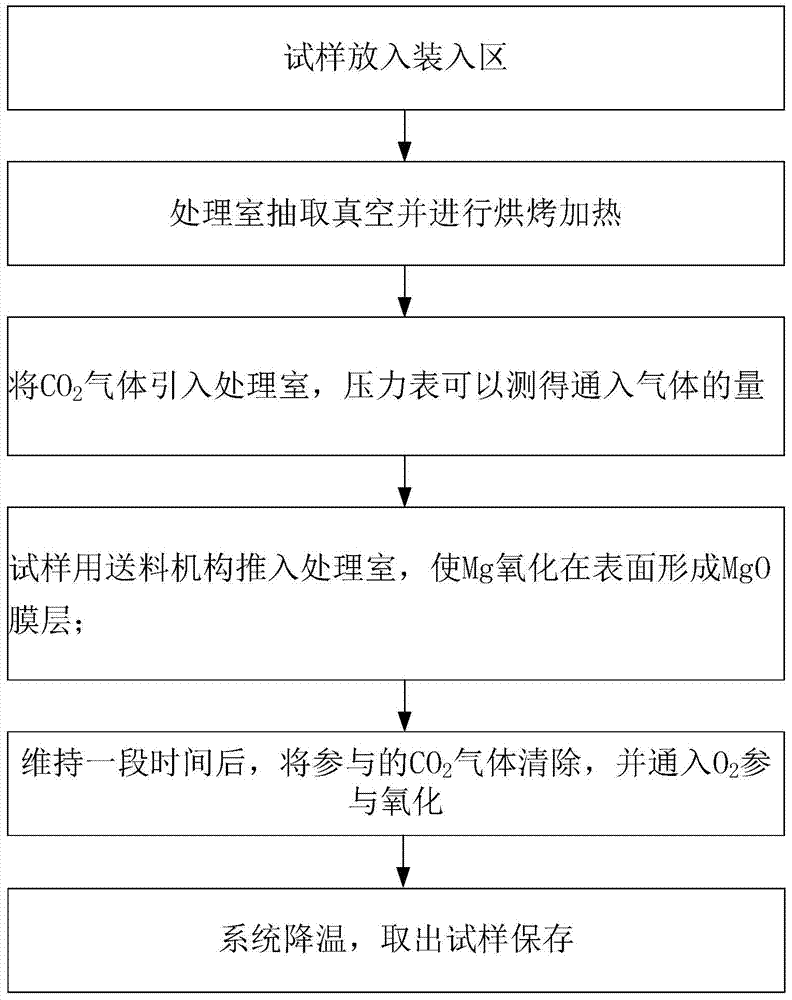

[0034] The invention provides a method for preparing an Ag-Mg alloy type MgO film for bombardment by high-energy particles. figure 1 The equipment shown was prepared. The equipment includes a processing chamber 4 and a loading area 6, the processing chamber 4 and the loading area 6 are connected by a pipeline, the pipeline is provided with a valve 5, the exhaust unit 12 is connected with the processing chamber 4 and the loading area 6, and the loading area 6 and N 2 Gas cylinder 8 and pressure gauge 9 are connected, and processing chamber 4 is connected to O 2 Cylinder 14, CO 2 Cylinder 15, N 2 Gas cylinder 16, pressure gauge 10 are connected. Concrete preparation steps are as follows:

[0035] Step 1, the sample is pretreated by the same pretreatment method as in the traditional preparation method, that is, the surface of the sample is degreased wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com