Mixer

A kneading machine and kneading technology, which is applied in the field of kneading machines, can solve problems such as easy accumulation of materials and uneven mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is further described in detail through specific implementation methods:

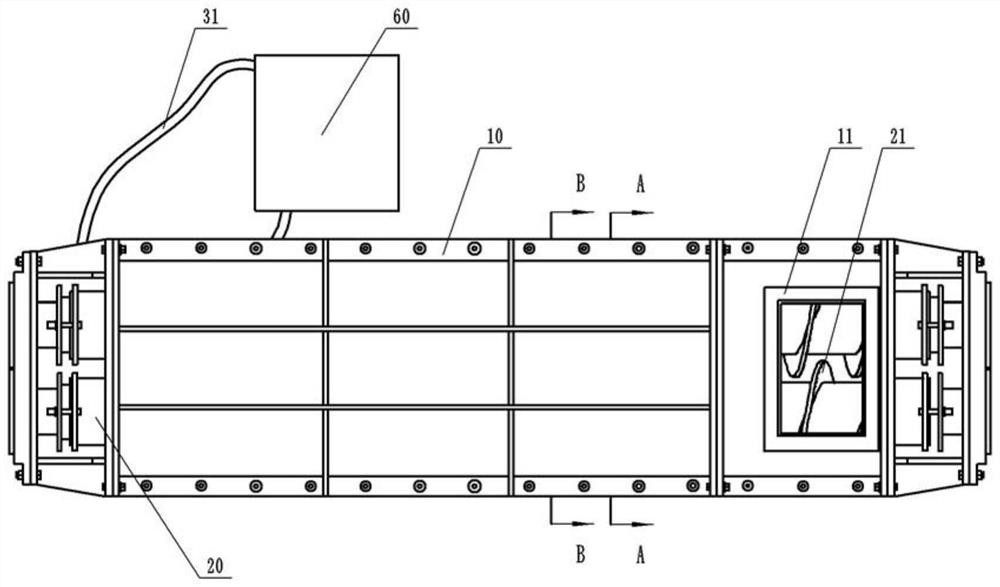

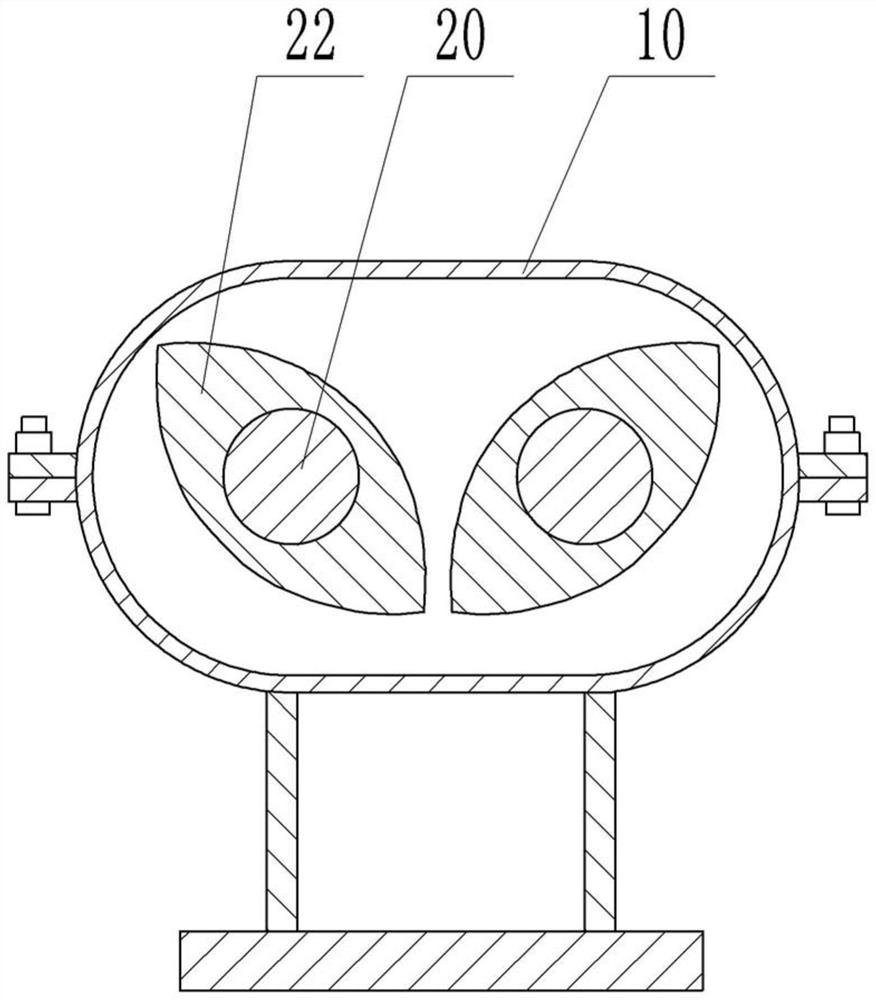

[0027] Instructions attached Figure 1-6 The reference signs in include: mixing cylinder 10, material inlet 11, discharge cylinder 12, rotor shaft 20, spiral blade 21, blade 22, transmission belt 23, power part 30, cooling pipe 31, closed space 32, transmission Shaft 40, cylindrical turning block 50, through groove 51, spring 52, baffle plate 53, cooling water tank 60, through cavity 61, plunger 62, connecting rod 621, one-way intake valve 63, one-way exhaust valve 64, rotating shaft 70, rotating vanes 71, cams 72, slots 721, cooling fins 80, cavities 81.

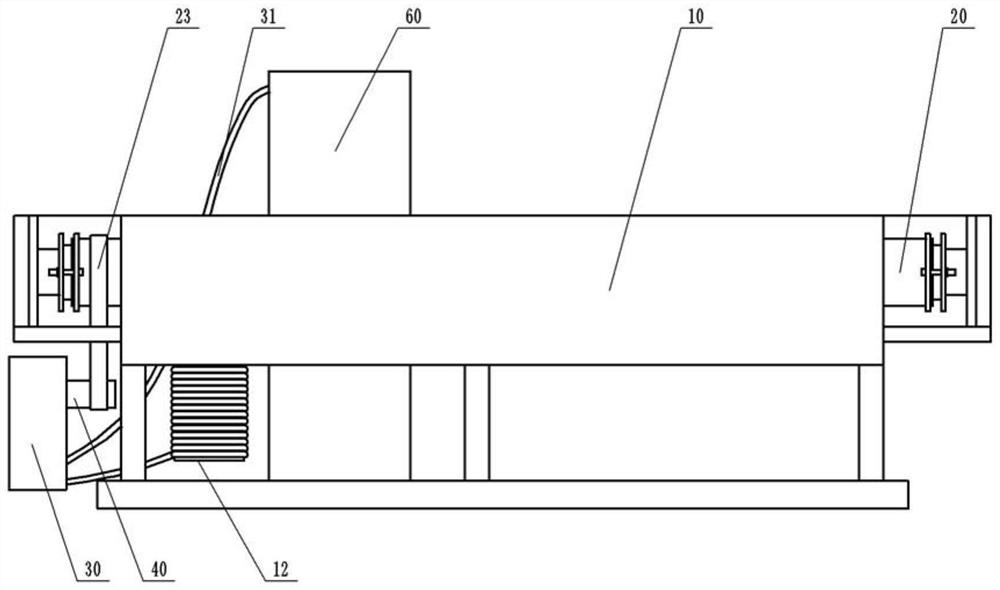

[0028] The embodiment is basically as attached figure 1 , attached figure 2 Shown: a mixing machine, including a mixing cylinder 10, a cooling system and a pair of rotor shafts 20, a pair of rotor shafts 20 run through the left and right sides of the mixing cylinder 10 and are connected to the mixing cylinder 10 in rotation, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com