Low-odor low-VOC (low volatile organic compounds) polyurethane high-elastic foam

A polyurethane, low-odor technology, applied in the field of foam materials and their preparation, can solve the problem of low dosage of additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

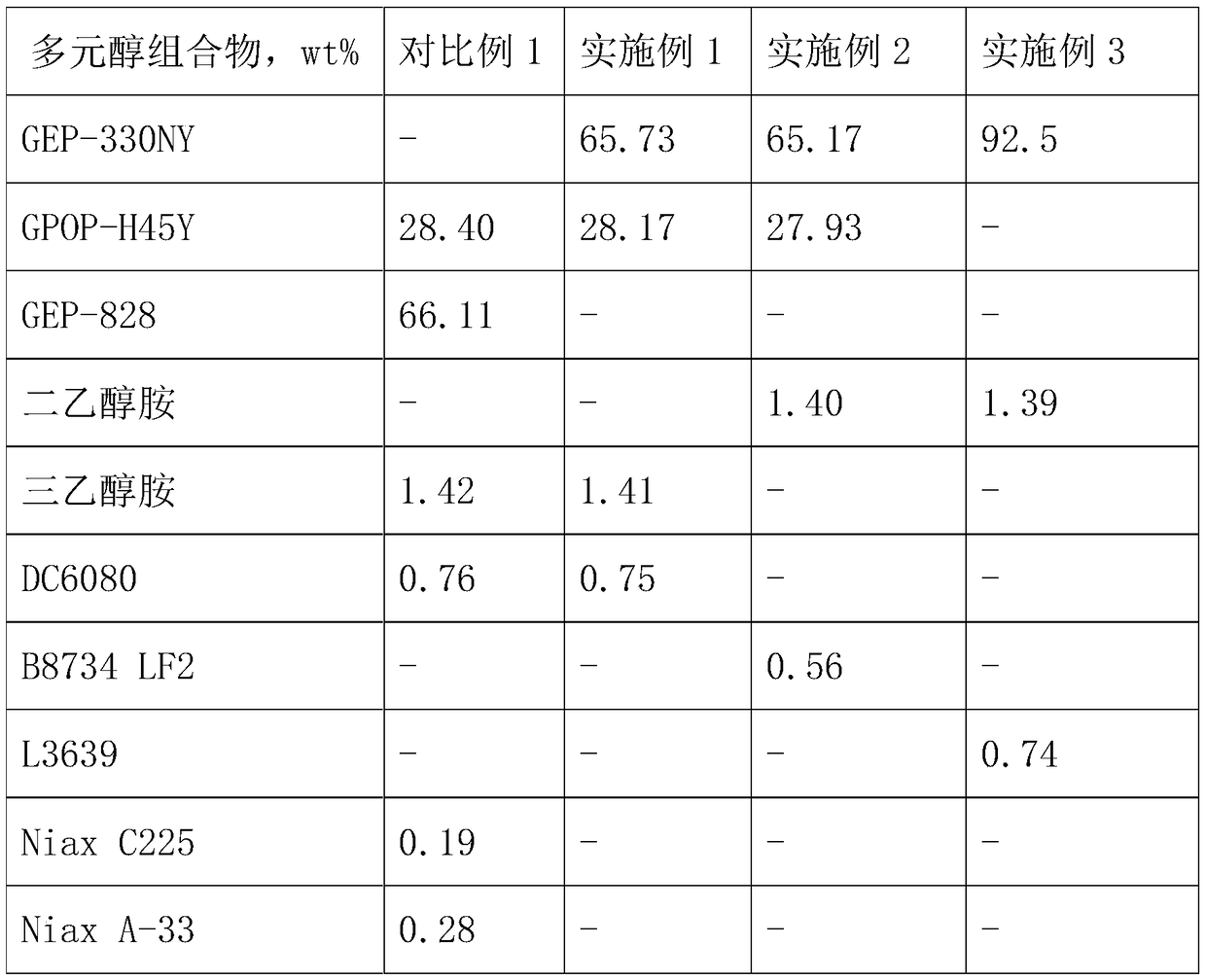

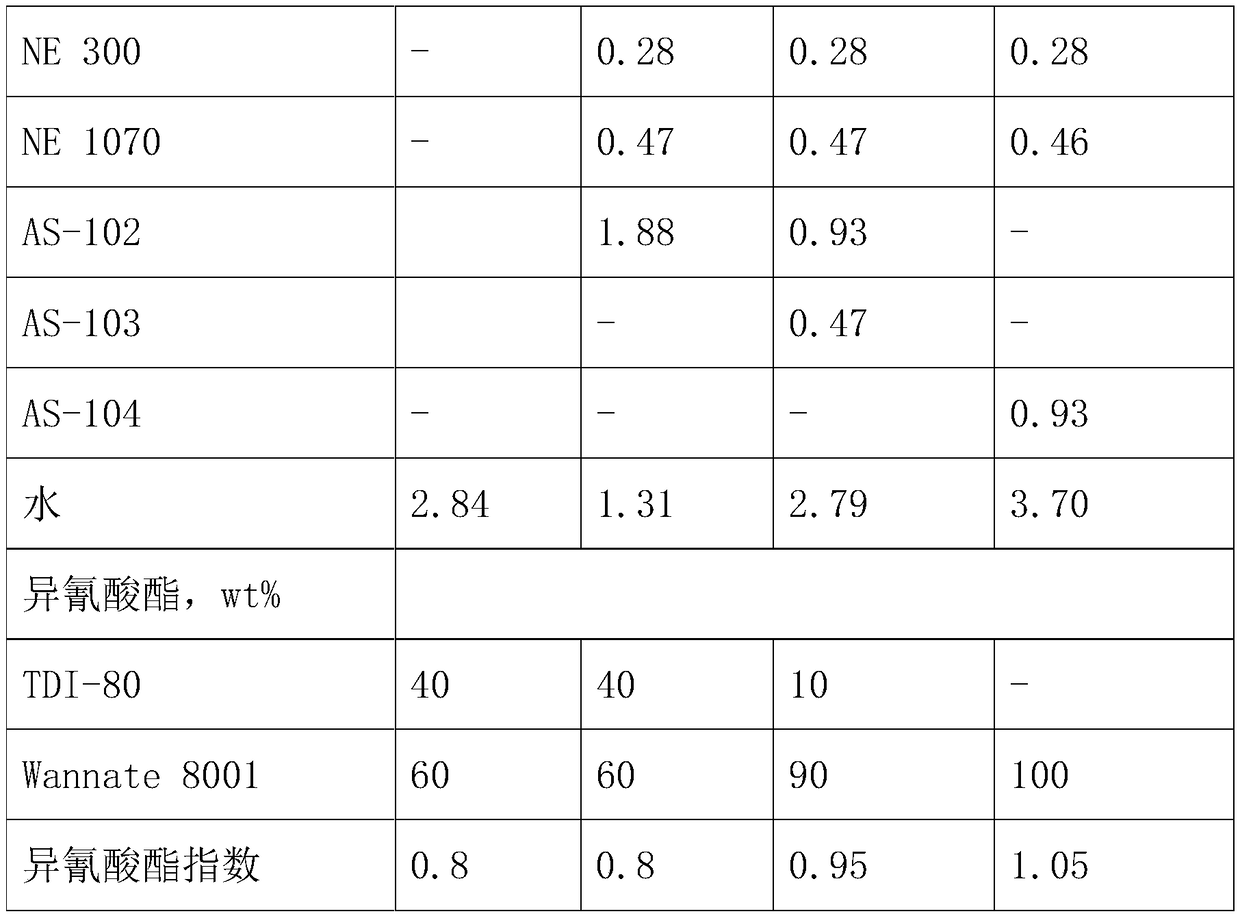

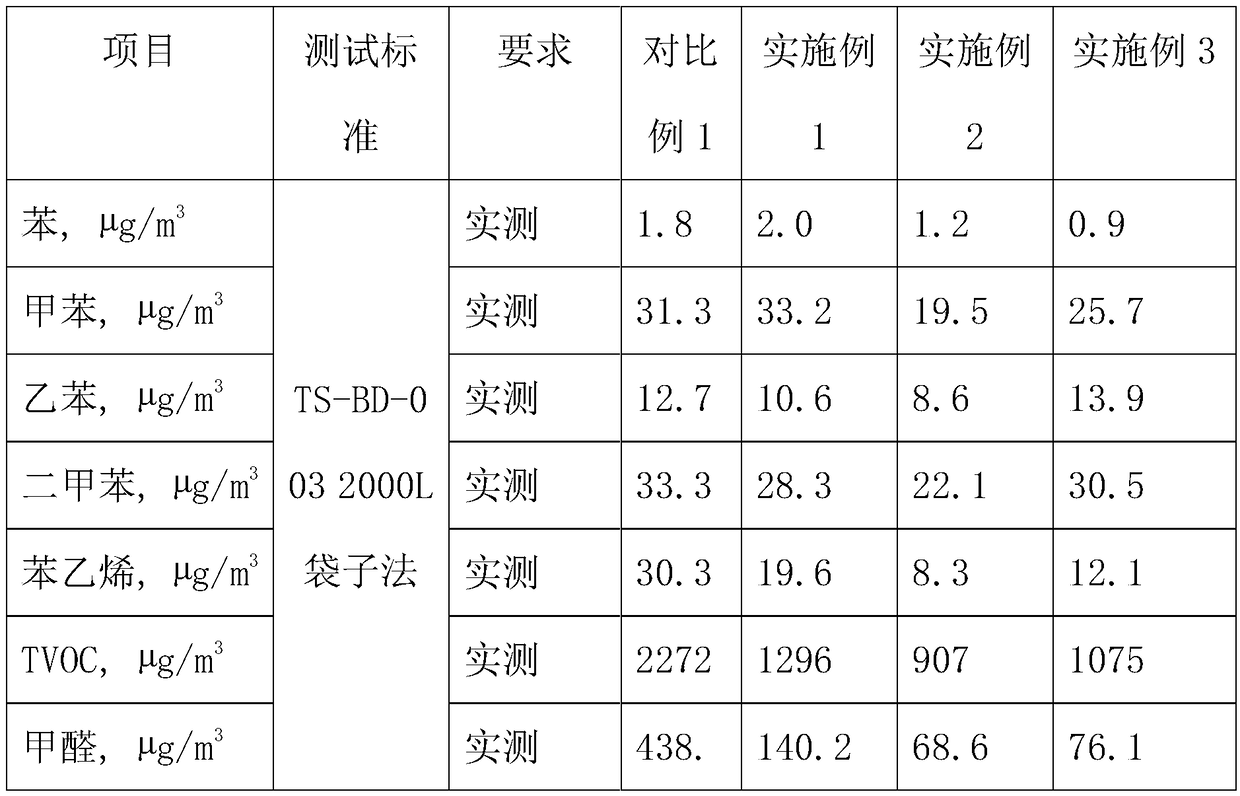

[0025] Table 1 is the formula of comparative example 1 and embodiment 1-3 product:

[0026] Table 1 embodiment formula

[0027]

[0028]

[0029] The raw materials stated in the table are:

[0030] GEP-330NY: Highly reactive polyether polyol, hydroxyl value 35mg KOH / g, functionality 3, formaldehyde content: 1.7μg / g, acetaldehyde content: 2.1μg / g, acrolein content: 0.8μg / g, Sinopec Shanghai Takahashi Branch;

[0031] GPOP-H45Y: Highly active polymer polyether polyol, hydroxyl value 21mg KOH / g, functionality 3, formaldehyde content: 2.3μg / g, acetaldehyde content: 4.1μg / g, acrolein content: N.D., Sinopec Shanghai High bridge branch;

[0032] GEP-828: Highly active polyether polyol, hydroxyl value 28mg KOH / g, functionality 3, formaldehyde content: 4.2μg / g, acetaldehyde content: 5.8μg / g, acrolein content: 4.4μg / g, Sinopec Shanghai Takahashi Branch;

[0033] Diethanolamine: commercially available;

[0034] Triethanolamine: commercially available;

[0035] DC6080, B8734 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com