Compound antibacterial coating containing silicon dioxide and preparation method thereof

A compound antibacterial and silicon dioxide technology, which is applied to biocide-containing paints, antifouling/underwater coatings, coatings, etc., can solve the problems of poor wear resistance of antibacterial coatings, hindering drug efficacy, uneven drug distribution, etc. , to achieve the effect of strong wear resistance, expanding the scope of application, and long duration of sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

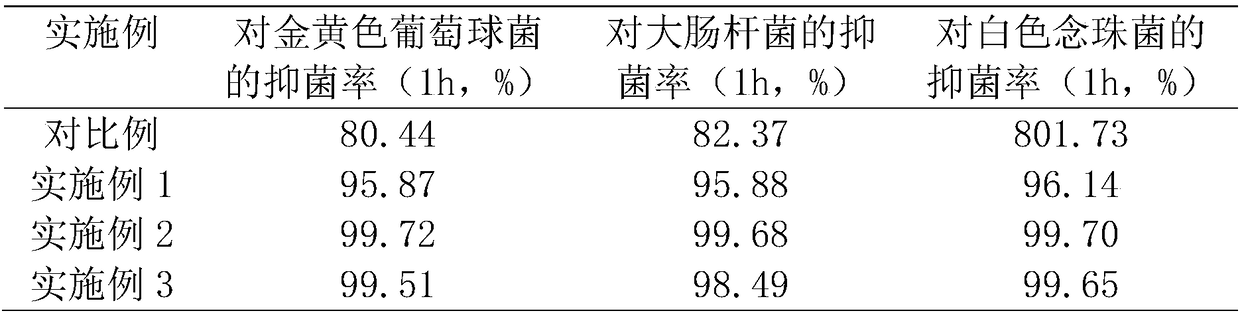

Examples

Embodiment 1

[0058] Embodiment 1: adopt method one to prepare the composite antibacterial coating containing silicon dioxide

[0059] 1) Take a certain amount of micron silver powder, put it into the radio frequency induction plasma powder making equipment, heat and spheroidize the powder, add 20wt% absolute ethanol to the prepared powder, disperse at a high speed, and then classify with a tubular centrifuge 2- 3 times, finally get a powder with good dispersibility and dry it in a vacuum oven at 35-45°C for use;

[0060] 2) Take a certain amount of Ti(OH) 4 , using radio frequency induction plasma to prepare nano-titanium dioxide powder, add 20wt% absolute ethanol to the prepared powder, disperse at high speed, then classify 2-3 times with a tubular centrifuge, and finally get a powder with good dispersibility at 35- Dry in a vacuum oven at 45°C for use;

[0061] 3) Preparation of composite antibacterial coating containing silicon dioxide:

[0062] ①Weigh the solid powder in proportion:...

Embodiment 2

[0069] Embodiment 2: adopt method two to prepare the composite antibacterial coating containing silicon dioxide

[0070] 1) Take a certain amount of micron silver powder, put it into the radio frequency induction plasma powder making equipment, heat and spheroidize the powder, add 20wt% absolute ethanol to the prepared powder, disperse at a high speed, and then classify with a tubular centrifuge 2- 3 times, finally get a powder with good dispersibility and dry it in a vacuum oven at 35-45°C for use;

[0071] 2) Take a certain amount of TiO(OH) 2 , using radio frequency induction plasma to prepare nano-titanium dioxide powder, add 20wt% absolute ethanol to the prepared powder, disperse at high speed, then classify 2-3 times with a tubular centrifuge, and finally get a powder with good dispersibility at 35- Dry in a vacuum oven at 45°C for use;

[0072] 3) Preparation of composite antibacterial coating containing silicon dioxide:

[0073] ① Weigh the solid powder in proportio...

Embodiment 3

[0080] Embodiment 3: adopt method three to prepare the composite antibacterial coating containing silicon dioxide

[0081] 1) Take a certain amount of micron silver powder, put it into the radio frequency induction plasma powder making equipment, heat and spheroidize the powder, add 20wt% absolute ethanol to the prepared powder, disperse at a high speed, and then classify with a tubular centrifuge 2- 3 times, finally get a powder with good dispersibility and dry it in a vacuum oven at 35-45°C for use;

[0082] 2) Take a certain amount of TiO 2 , using radio frequency induction plasma to prepare nano-titanium dioxide powder, add 20wt% absolute ethanol to the prepared powder, disperse at high speed, then classify 2-3 times with a tubular centrifuge, and finally get a powder with good dispersibility at 35- Dry in a vacuum oven at 45°C for use;

[0083] 3) Preparation of composite antibacterial coating containing silicon dioxide:

[0084] ① Weigh the solid powder in proportion:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com