Drilling stroke and pressure control system for vertical shaft sinking machine

A technology of pressure control and roadheader, which is applied to the automatic control system of drilling, drilling equipment, directional drilling, etc., and can solve the problem of improper control of the drilling process and drilling pressure of the excavation structure, complex cutter head structure, and affecting drilling efficiency, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

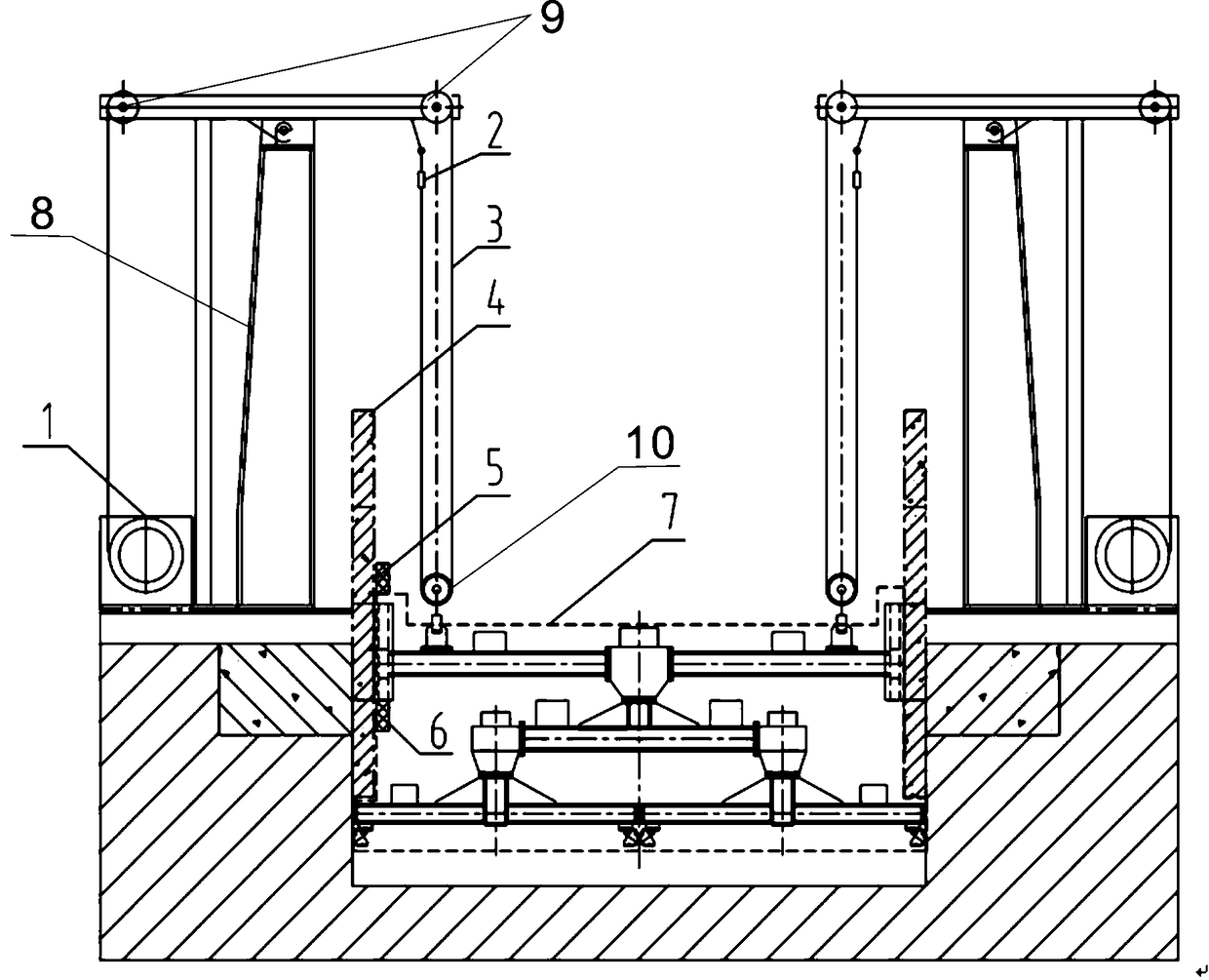

[0012] Such as figure 1 As shown, the drilling process and pressure control system for the sinking method shaft boring machine includes multiple synchronous winch systems, and the drilling speed is adjusted by controlling the flow rate of the synchronous hydraulic winch system to ensure the stable posture of the tunneling mechanism. It is distributed along the circumference of the shaft, corresponding to the multiple lifting positions on the shaft boring machine, and the multiple lifting positions are respectively arranged with movable pulleys 10; the synchronous winch system is composed of synchronous winch 1, wire rope 3 and bogie 8, and is set at the synchronous Two fixed pulleys 9 are installed on the bogie 8 on one side of the winch. One end of the steel wire rope is wound on the drum of the synchronous winch, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com