Fuel feeding proportion adjustable combustor

A burner and adjustable technology, applied in the field of manufacturing, can solve the problems of fluctuating flame, difficulty in stabilizing, and difficulty in adjusting flame direction, etc., to achieve the effect of changing blackness, improving glass quality, and good burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

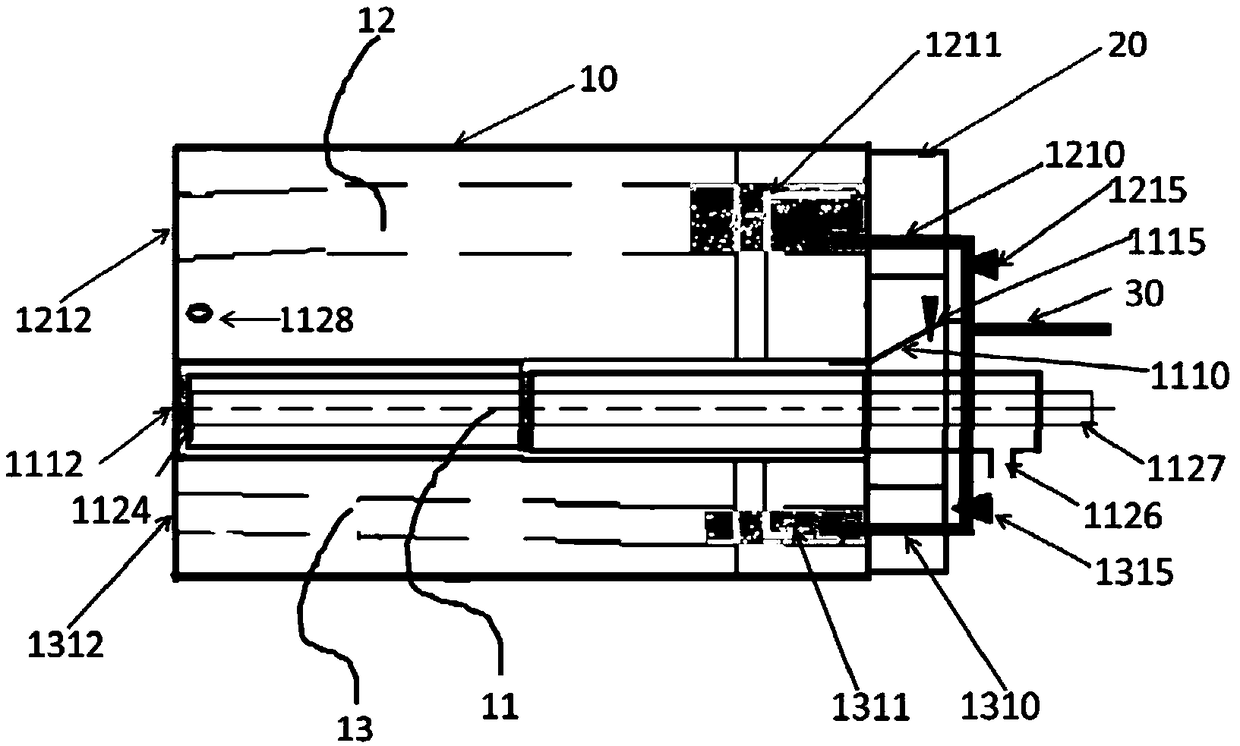

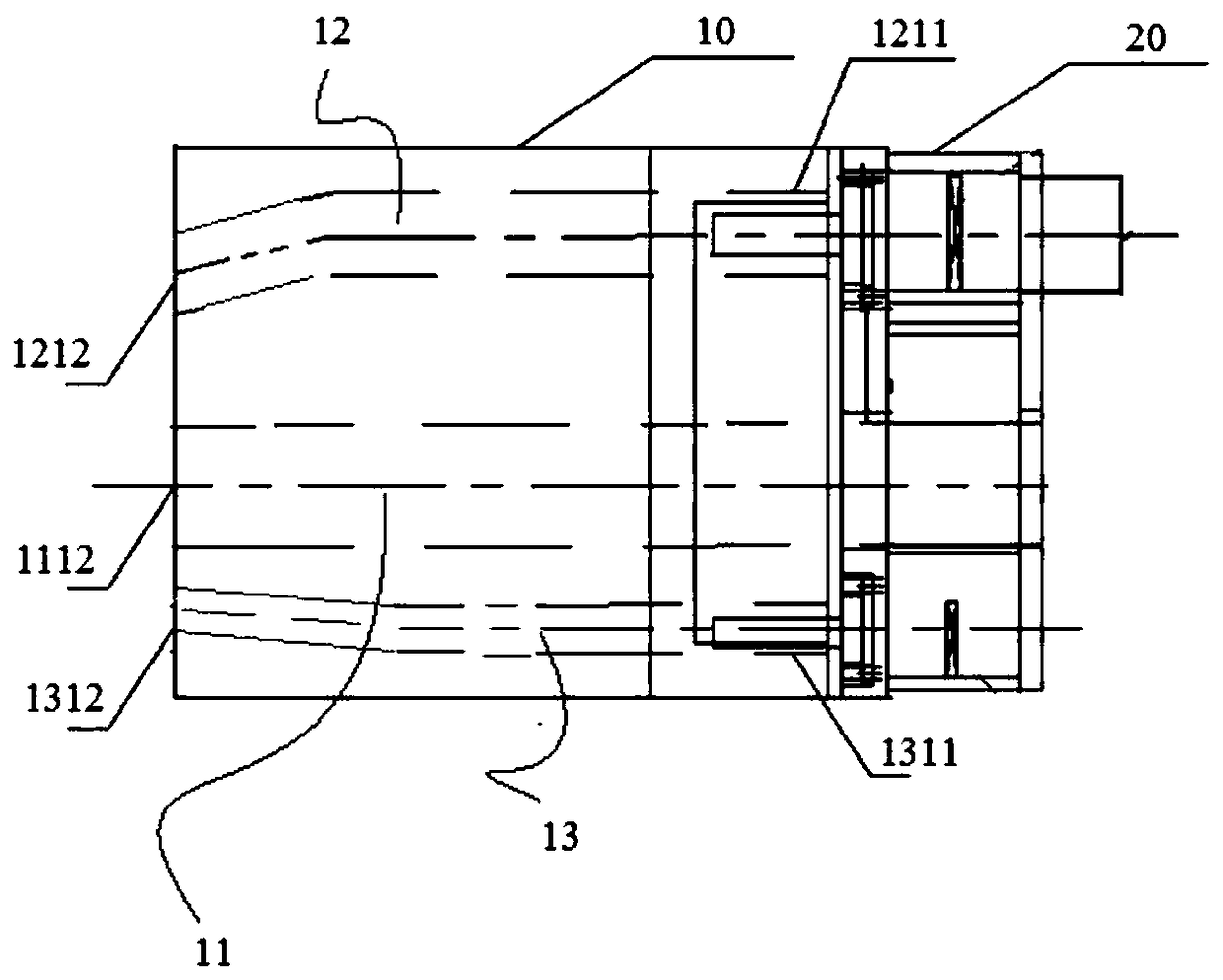

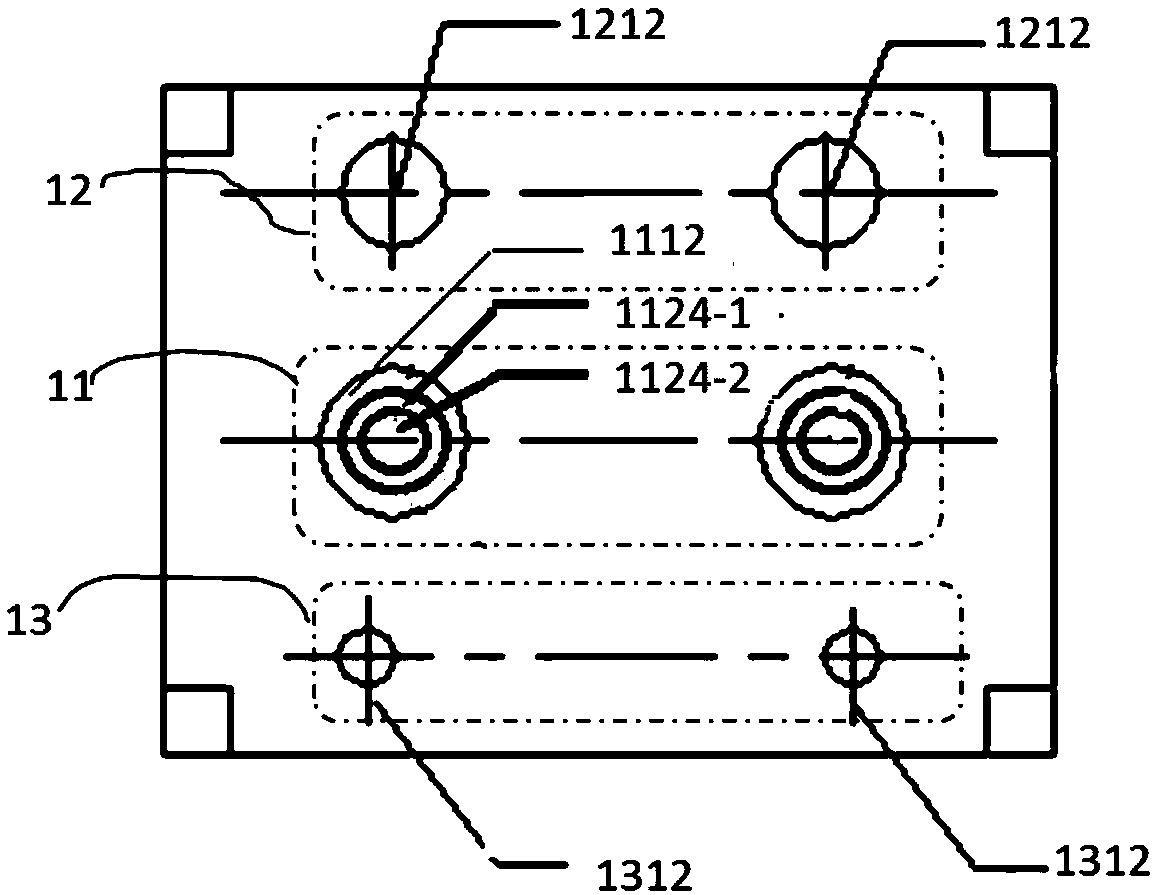

[0105] During the glass melting process, the figure 1 For the burner shown, the first outlet end of the first oxidizer passage of the burner has a first offset angle, and the first offset angle is selected as 2-8°, and the second outlet of the second oxidizer passage of the burner The end has a second offset angle, the second offset angle is selected from 1-5°, and the nozzle is selected Figure 4 The nozzle configuration shown, ie the outlet end of the nozzle does not have a diversion structure. The oxidant is pure oxygen, which is input from the main inlet 30, and the first oxidant supply system 12, the second oxidant supply system 13 and the fuel-third oxidant are respectively controlled by the first control unit 1215, the second control unit 1315, and the third control unit 1115. The oxidant flow distribution in the supply system 11 allows the oxidant to be mixed with the fuel at the desired time and location and maintains the desired flame direction. The second fuel is ...

Embodiment 2

[0107] The combustor and combustion method capable of adjusting the feeding ratio of the second fuel and the first fuel in the present invention will be described in detail below with reference to the embodiments.

[0108] In one embodiment of the present invention, a flat glass furnace with a daily output of 550 T / D adopts a typical sulfate-containing soda-lime-silica glass formula. Eleven burners are set at intervals on each side of the kiln, using pure oxygen / natural gas cross-flame combustion. A row of bubblers is installed in the kiln about 1800mm upstream of the hot spot. Under the designed target production conditions, the position of the target bubble boundary is about 1800mm upstream of the bubbler, and the position of the target material mountain line is about 1800mm upstream of the target bubble boundary. About 2500mm.

[0109] Due to the temperature difference between the hot spot and the feeding end, the surface glass liquid at the hot spot backflows toward the f...

Embodiment 3

[0119] The combustor and combustion method capable of adjusting the feed ratio of multiple fuels in the present invention will be described in detail below in conjunction with the examples. In this embodiment, the present invention can be used to control the combustion effect of fuels with unstable calorific value:

[0120] use Figure 5 For the burner shown, the first outlet end of the first oxidant passage of the burner has a first offset angle, and the first offset angle is selected as 6°, and the second outlet end of the second oxidizer passage of the burner has The second offset angle, the second offset angle is selected as 3°, and the nozzle is selected Figure 4The nozzle configuration shown, ie the outlet end of the nozzle does not have a diversion structure. The oxidant is pure oxygen, which is input from the main inlet, and the first control unit 1215, the second control unit 1315, and the third control unit 1115 control the first oxidant supply system 12, the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com