Four-corner tangential firing boiler and method for reducing furnace coking and outlet smoke temperature difference

A four-corner tangential and boiler technology, which is applied in the direction of combustion method, combustion air/fuel supply, combustion equipment, etc., to achieve the effects of reducing powder loss, reducing smoke temperature deviation, and maintaining rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

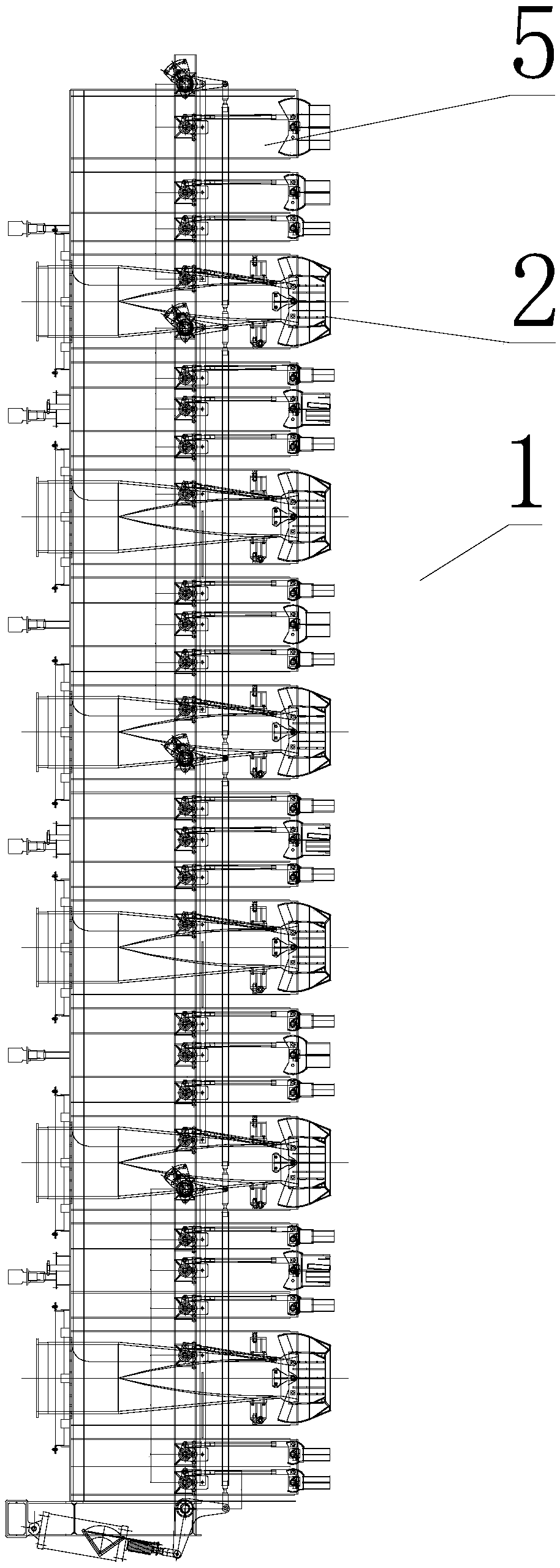

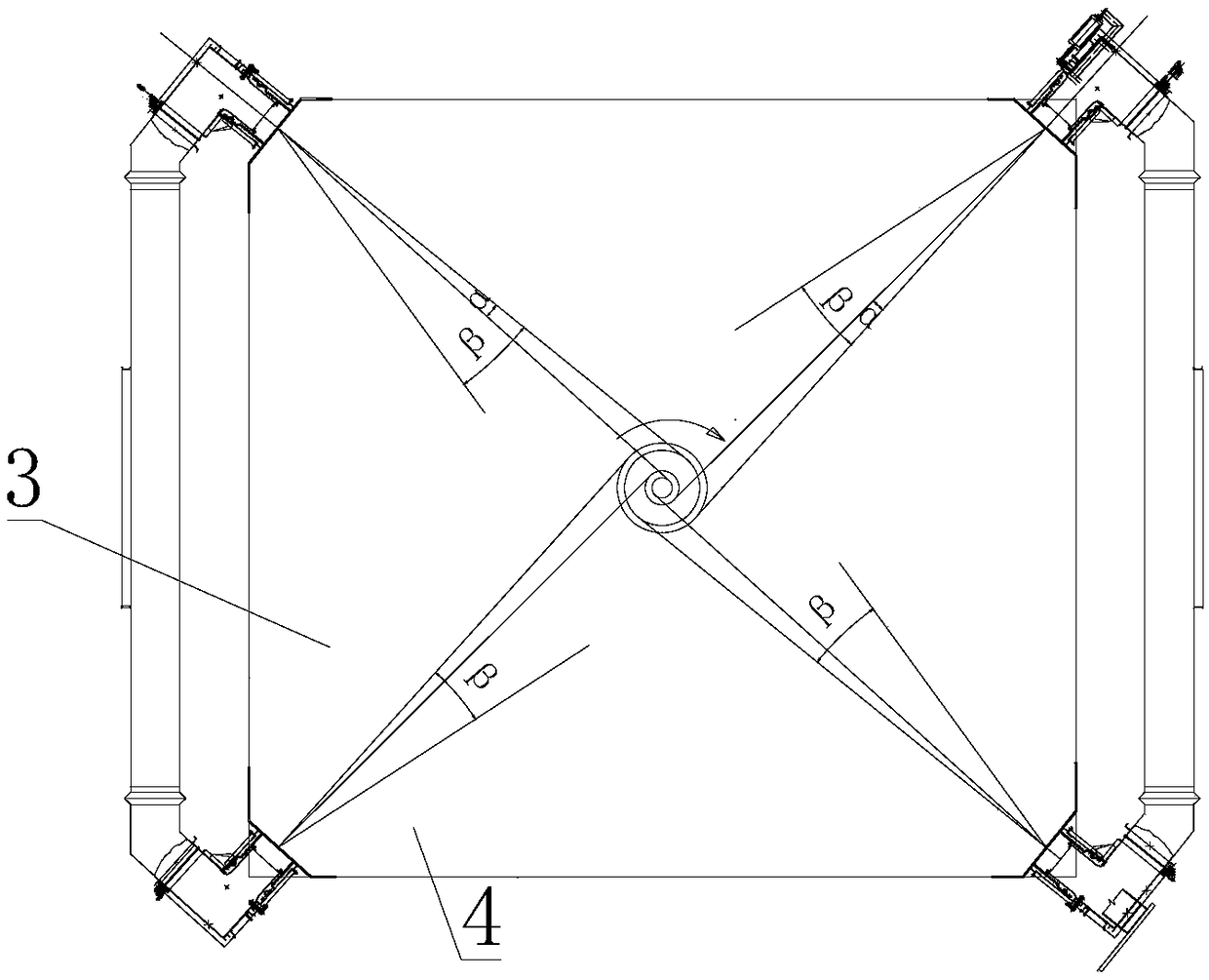

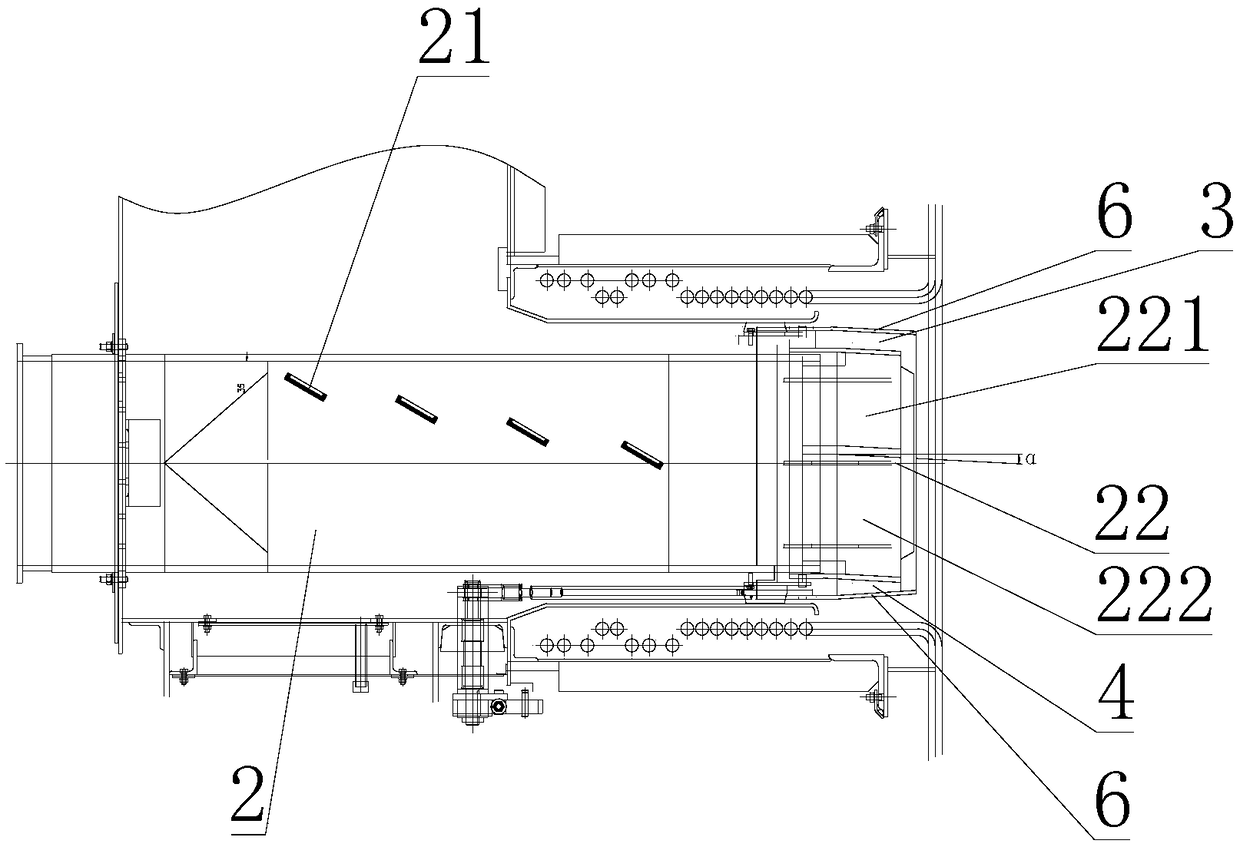

[0019] refer to figure 1 , figure 2 and image 3 , the four-corner tangential combustion boiler of the present invention includes a burner 1, and the burner 1 is respectively equipped with a horizontal thick-thin primary air nozzle 2 on the four corners of the same layer, and the inside of the horizontal thick-thin primary air nozzle 2 is spaced obliquely along the length direction A number of horizontal thick-thin deflectors 21 are provided. In this embodiment, the horizontal thick-thin deflectors 21 are guide vanes, and there are 4 pieces in total, which can make the primary air mixture graded to form two phases of thick and thin. According to the embodiment The coal-fired characteristics of the project, the density ratio is 6:4. A primary air nozzle 22 with a deflection angle α is provided at the end of the horizontal thick-thin primary air nozzle 2, and the deflection angle α of the primary air nozzle 22 is set to 3°-10°. In this embodiment, the deflection angle α is se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com