Low-damping capacitive acceleration sensor and preparation method thereof

An acceleration sensor, capacitive technology, applied in the measurement of acceleration, speed/acceleration/shock measurement, instruments, etc., can solve the problems of unreachable, high sensitivity, unadjustable, etc., to reduce the damping coefficient of the film, reduce the system noise, The effect of increasing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

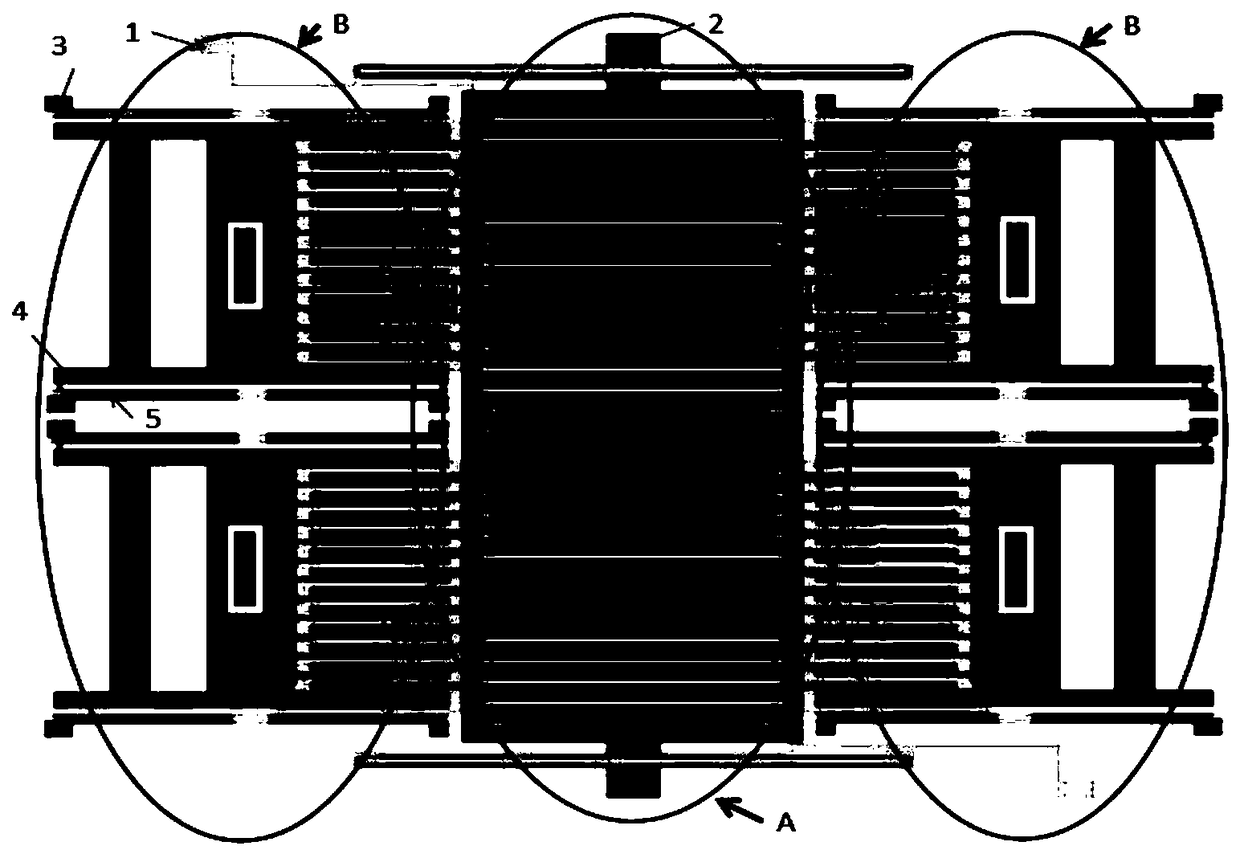

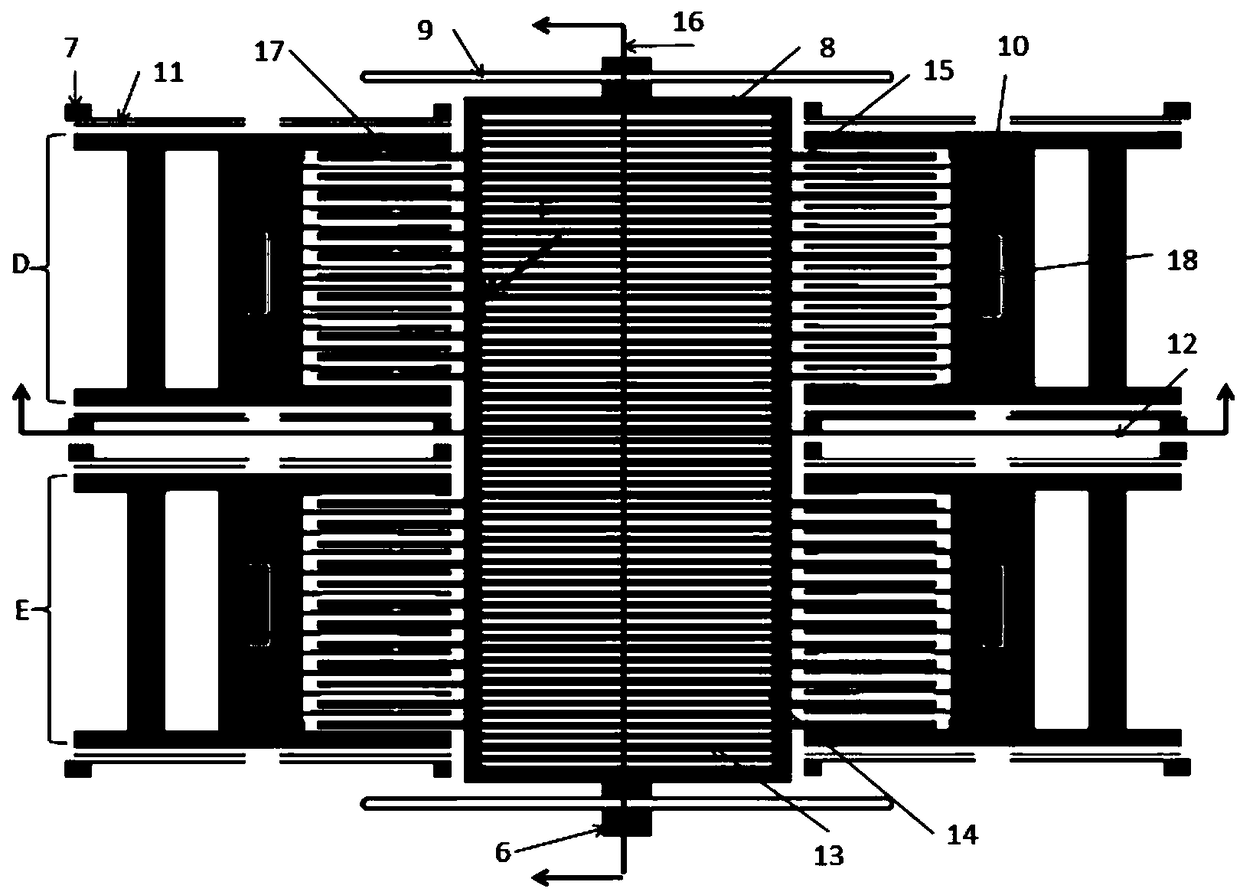

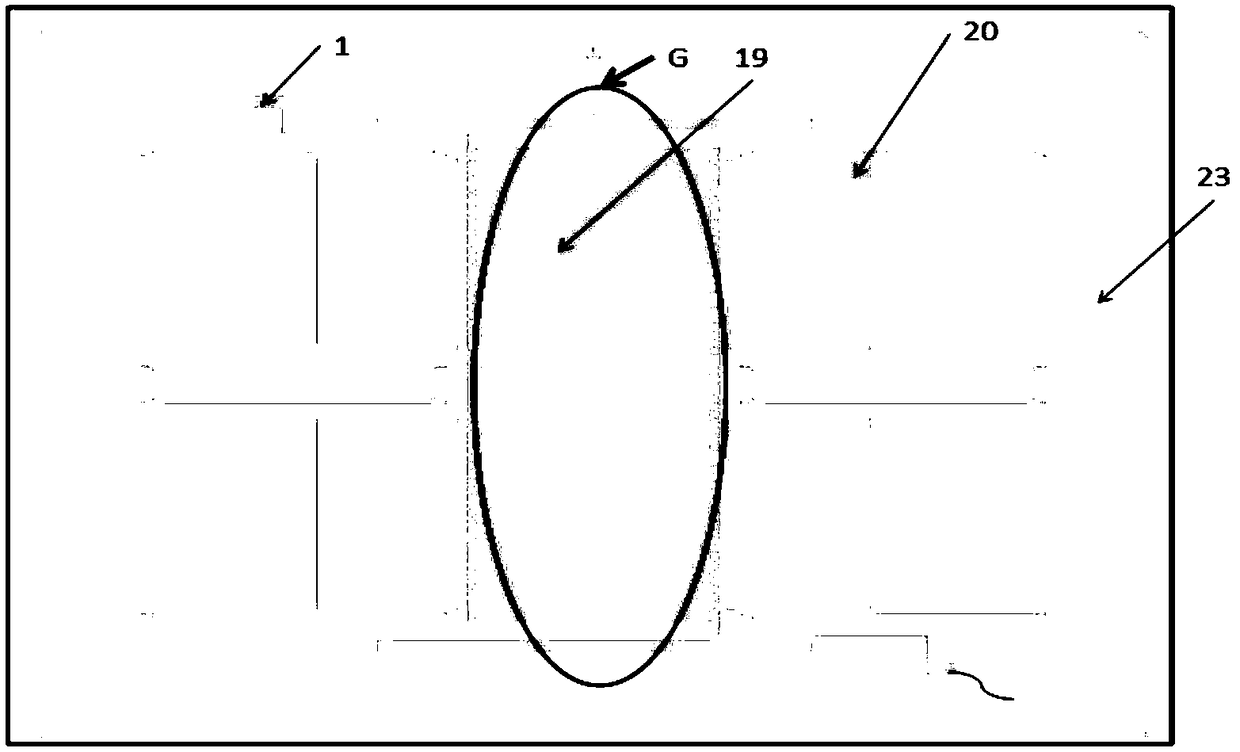

[0044] combine Figure 1 to Figure 5 , the overall structure of the present invention will be described.

[0045] A low-damping capacitive acceleration sensor comprises a glass substrate 23 and an aluminum electrode 19 on its upper surface, a first electrode lead point 1 on the aluminum electrode 19, a first anchor point 6 and a second anchor point fixed on the glass substrate 23. An anchor point 7, a second electrode lead point 2 on the first anchor point 6, a third electrode lead point 3 on the second anchor point 7, a silicon sensitive mass 8 that can move longitudinally over the aluminum electrode 19, The first U-shaped silicon cantilever beam 9 that connects the first anchor point 6 with the silicon sensitive mass 8, the silicon fixed electrode 10 that is suspended above the aluminum electrode 19 and can move longitudinally, connects the second anchor point 7 with the silicon fixed electrode 10 connected to the second U-shaped silicon cantilever beam 11 , the second alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com