Manufacturing method for aluminum honeycomb cores

A manufacturing method, the technology of aluminum honeycomb, applied in the direction of material gluing, connecting components, mechanical equipment, etc., can solve the problems of irregular aluminum honeycomb core cells, poor product quality stability, and limited application fields, so as to reduce processing and manufacturing costs, The effect of high degree of processing automation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

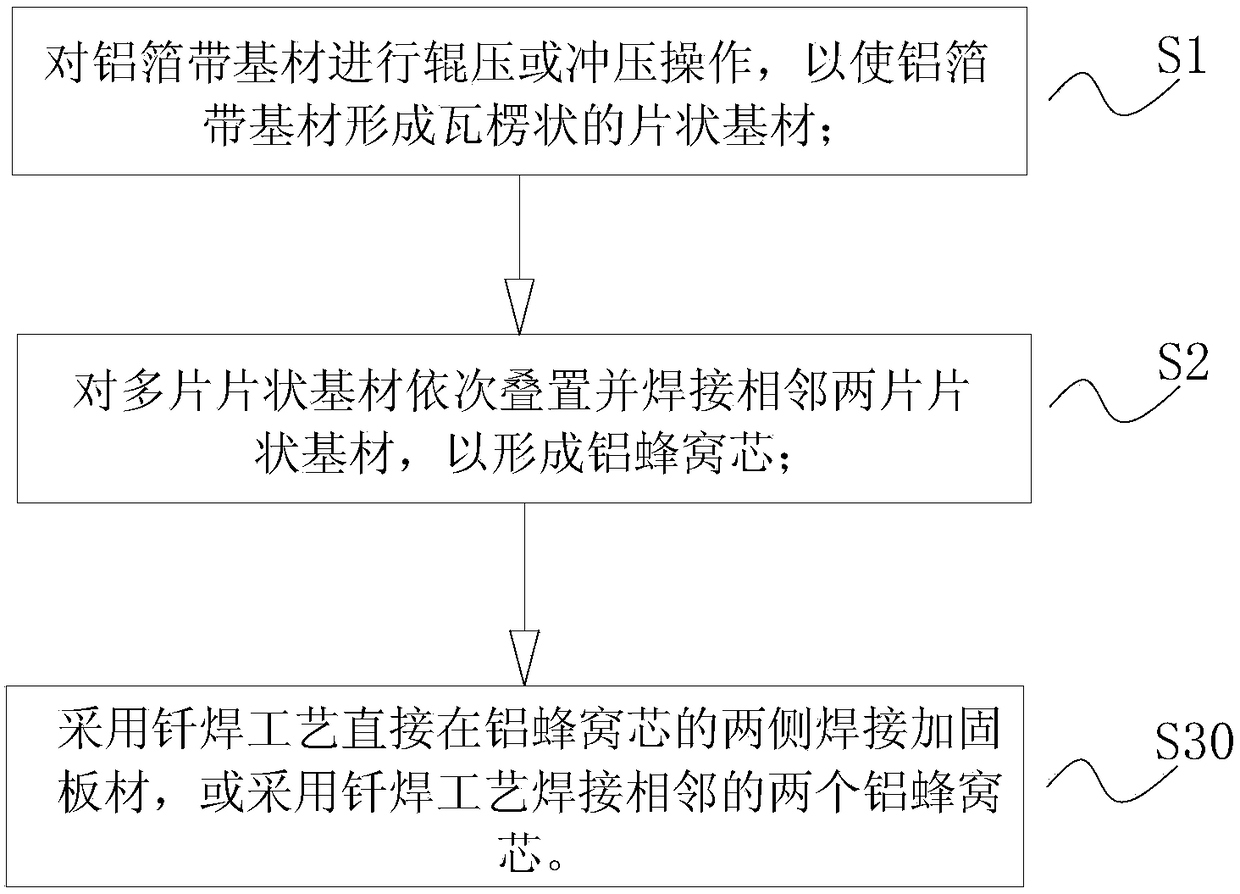

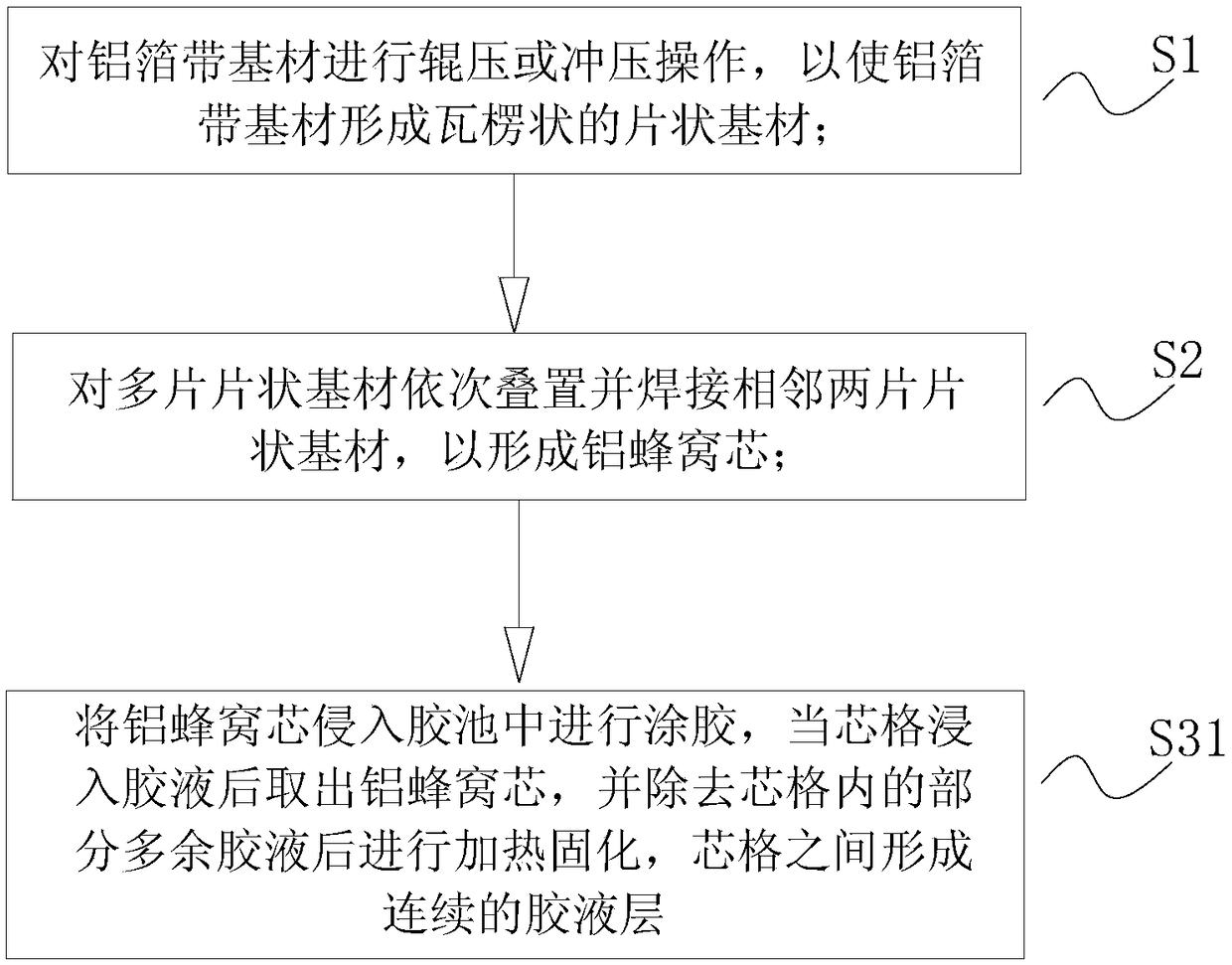

[0036] Such as figure 2 , Figure 5 to Figure 7 As shown, the manufacturing method of the aluminum honeycomb core includes: Step S1, rolling or stamping the aluminum foil strip substrate 201, so that the aluminum foil strip substrate 201 forms a corrugated sheet substrate 100; and Step S2, for multiple The sheet-shaped substrates 100 are stacked sequentially and two adjacent sheet-shaped substrates 100 are welded to form the aluminum honeycomb core 1 .

[0037] The manufacturing method of this aluminum honeycomb core effectively avoids the stretching process in the traditional manufacturing method, that is, does not rely on the stretching process to form a hexagonal core grid, so the aluminum honeycomb core 1 provided by the present invention is used to manufacture The aluminum honeycomb core 1 is not limited by the condition of being stretched and formed into a hexagon, which solves the problem that the sheet-like base material 100 is too thick or too wide to be easily stre...

Embodiment 2

[0056] Such as figure 1 As shown, the difference between this embodiment and Embodiment 1 is that step S30 is also included after step S2, using a brazing process to directly weld reinforcement plates on both sides of the aluminum honeycomb core 1, or using a brazing process to weld reinforcement plates on both sides of the aluminum honeycomb core 1 Welding between core layers. If the reinforcement plates are welded on both sides of the aluminum honeycomb core 1 or the two adjacent honeycomb cores 1 are welded by brazing, there is no need to use the dipping process on the aluminum honeycomb core 1, and the structural strength of the aluminum honeycomb core 1 can also be improved. . Welding two adjacent aluminum honeycomb cores 1 by brazing process includes brazing between corrugated sheet substrates 100. Compared with the cemented aluminum honeycomb core 1 after brazing, the aluminum honeycomb core 1 can make the core layer A firm metallurgical bond is formed between them, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com