Fiber reinforced composite sleeper and preparation method thereof

A fiber-reinforced sleeper technology, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of thin profiles and limited preparation, and achieve the effects of increasing shear strength, improving durability, and improving the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

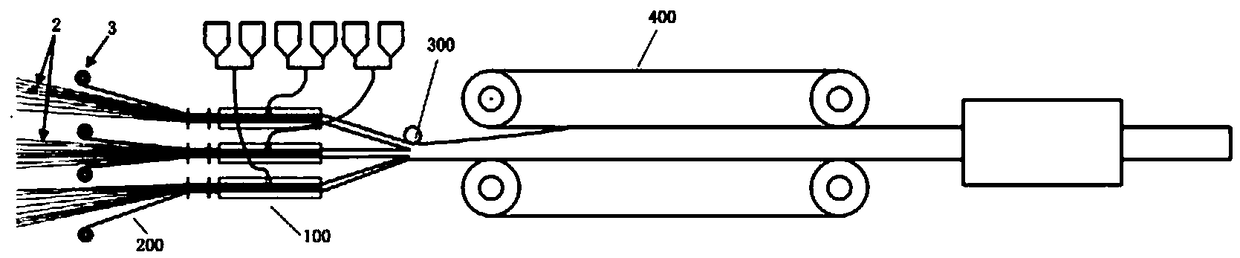

[0038] like Figure 1-3 As shown, the embodiment of the present invention provides a method for preparing a fiber-reinforced synthetic sleeper, comprising the following steps:

[0039] S1. Guide the yarn, import the reinforcing fiber material into the injection box 100;

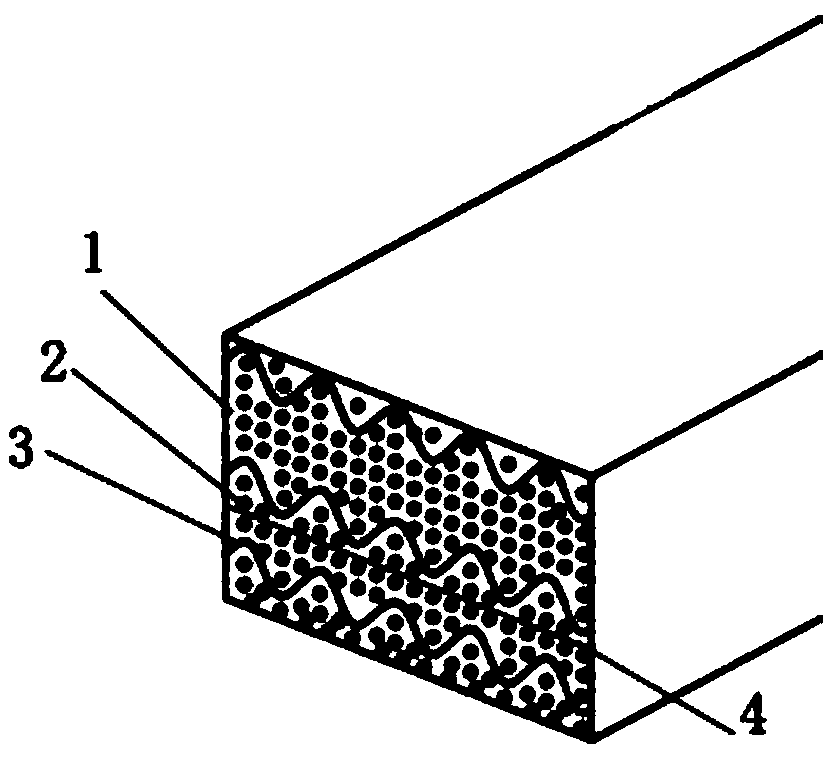

[0040] S2. Impregnation, injecting the foamed resin matrix 1 into the injection box 100, so that the reinforcing fiber material is impregnated in the foamed resin matrix 1;

[0041] S3. Post-processing, extruding, molding, cooling and cutting the foamed resin matrix 1 with the reinforcing fiber material distributed inside and / or on the surface to obtain the fiber reinforced synthetic sleeper.

[0042]Wherein, the yarn guiding in step S1 refers to guiding at least one of the reinforcing fiber materials into the injection box 100 through the yarn guiding device 200 . The reinforcing fiber material can be any one or several fiber rovings of 1200tex-9600tex, and can also be expanded into ply yarns. The yarn gu...

Embodiment 1

[0051] In this embodiment, three injection boxes 100 are used to prepare the fiber-reinforced composite sleeper. Each injection box 100 has the same size, 235 mm in width, 14 mm in thickness, and 1500 mm in length. The width is 235mm and the surface density is 300g / m 3 There are 4 layers of glass fiber grid cloth, which are arranged on the upper and lower ends of the upper and lower injection boxes 100 and 100 respectively, and enter the injection cavity 104 together with the glass fibers. In terms of parts by mass, the formula of the fiber-reinforced synthetic sleeper is as follows: 100 parts of polyurethane isocyanate, 100 parts of polyol mixture, 30 parts of glass fiber grid cloth, and 170 parts of continuous glass fiber. The reinforcing fiber content is 50% in total.

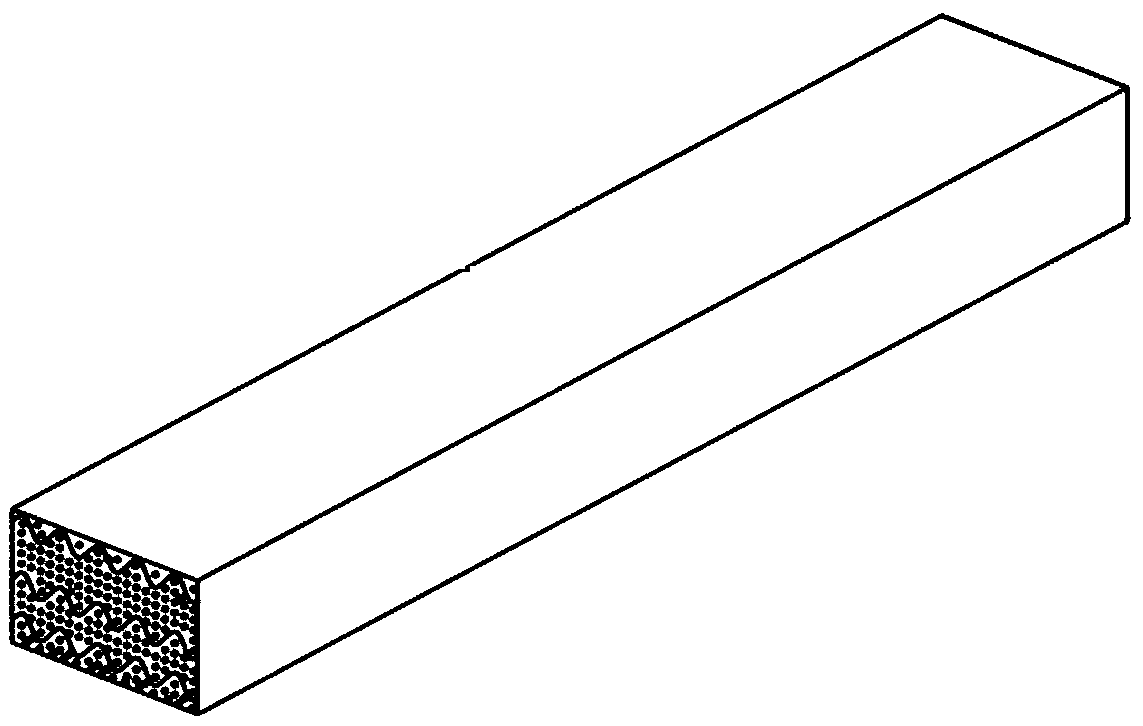

[0052] Through steps S1 to S3, the production density is 740kg / m 3 Several synthetic sleepers were bonded to each other to obtain an integral synthetic sleeper with a thickness of 75mm. Then two integral ...

Embodiment 2

[0054] In this embodiment, six glue injection boxes 100 are used, and each of the glue injection boxes 100 has the same size, 235mm in width, 14mm in thickness, and 1500mm in length. With a width of 235mm and a surface density of 300g / m 3 There are 6 layers of glass fiber grid cloth, which enter the glue injection cavity 104 together with the glass fibers. In terms of parts by mass, the formula of the fiber-reinforced synthetic sleeper is as follows: 100 parts of polyurethane isocyanate, 100 parts of polyol mixture, 40 parts of glass fiber grid cloth, and 200 parts of continuous glass fiber. The reinforcing fiber content is 55% in total.

[0055] Through steps S1 to S4, the production density is 740kg / m 3 , a synthetic sleeper base material with a thickness of 145mm. The synthetic sleeper base material is made into such a Figure 8 Synthetic sleeper products shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com