Preparation method of ultrathin cubic born nitride film

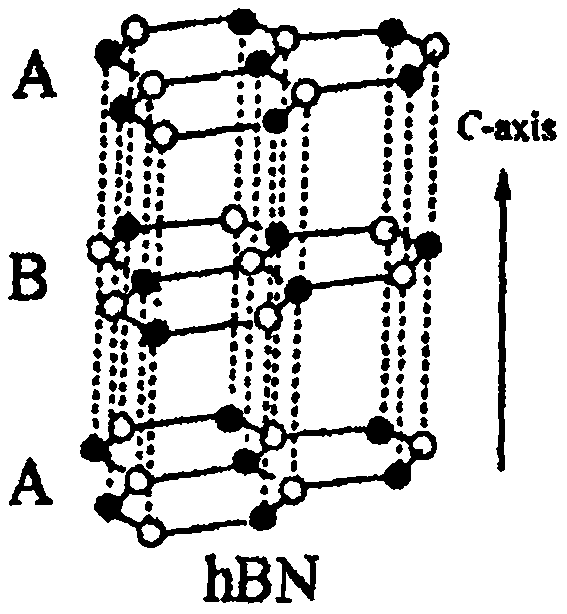

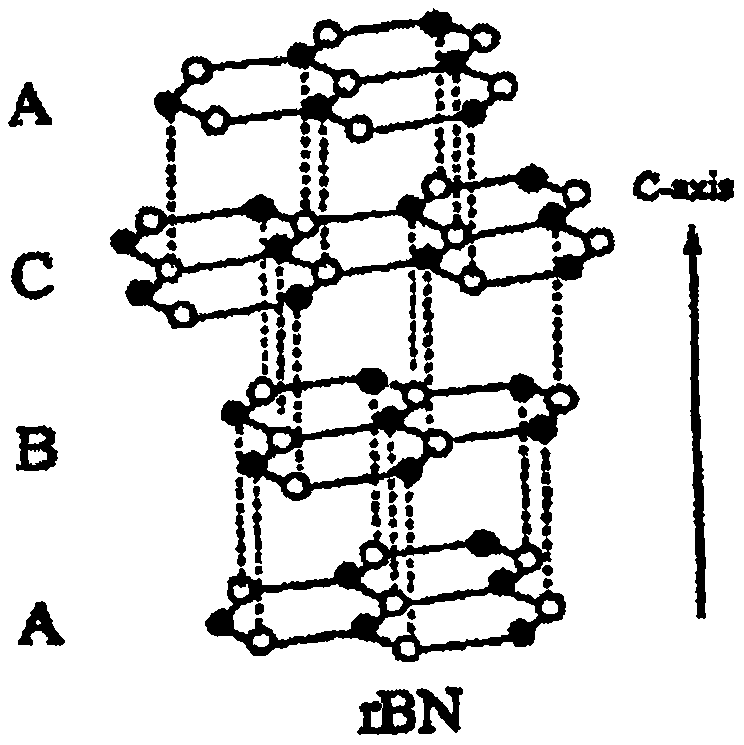

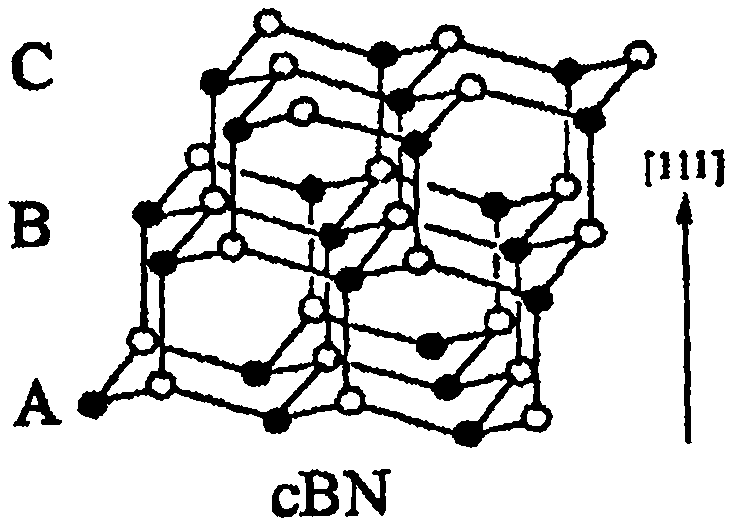

The technology of cubic boron nitride and boron nitride, which is applied in the field of cubic boron nitride preparation, can solve the problems of low synthesis rate and low utilization rate of raw materials, and achieve the effects of low cost, easy industrialized mass production and improved conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Put 4.73g of sodium amide and 3.5g of boron oxide into an autoclave, raise it from room temperature to 600°C at a rate of 10°C / min, and maintain at 600°C for 6 hours.

[0026] (2) After washing the product with concentrated hydrochloric acid and deionized water, put it into a vacuum oven, heat it to 60° C., and keep it for 4 hours.

[0027] (3) Put the trigonal boron nitride powder into a ball mill jar, pour in nitrogen gas as a protective gas, and ball mill it at room temperature for 20 hours at a speed of 700 r / min to obtain two-dimensional boron nitride.

[0028] (4) Fully mix two-dimensional boron nitride powder with a mass ratio of 100:5:5:7, lithium nitride, titanium nitride, and aluminum nitride powder, and press it into a cylindrical shape.

[0029] (5) Put it into the top press, and process under high temperature and high pressure, the temperature is 1400°C, the pressure is 4.0GPa, and the time is 5min.

[0030] (6) Take out the product, and use acid-base ...

Embodiment 2

[0032] (1) Put 4.73g of sodium amide and 3.5g of boron oxide into an autoclave, raise it from room temperature to 600°C at a rate of 10°C / min, and maintain at 600°C for 8 hours.

[0033] (2) After washing the product with concentrated hydrochloric acid and deionized water, put it into a vacuum oven, heat it to 60° C., and keep it for 4 hours.

[0034] (3) Put the trigonal boron nitride powder into a ball mill jar, pour in nitrogen gas as a protective gas, and ball mill it at room temperature for 20 hours at a speed of 700 r / min to obtain two-dimensional boron nitride.

[0035] (4) Fully mix two-dimensional boron nitride powder with a mass ratio of 100:5:5:7, lithium nitride, titanium nitride, and aluminum nitride powder, and press it into a cylindrical shape.

[0036] (5) Put it into the top press, and process under high temperature and high pressure, the temperature is 1400°C, the pressure is 4.0GPa, and the time is 5min.

[0037] (6) Take out the product, and use acid-base ...

Embodiment 3

[0039] (1) Put 4.73g of sodium amide and 3.5g of boron oxide into an autoclave, raise it from room temperature to 600°C at a rate of 10°C / min, and maintain at 600°C for 6 hours.

[0040] (2) After washing the product with concentrated hydrochloric acid and deionized water, put it into a vacuum oven, heat it to 60° C., and keep it for 4 hours.

[0041] (3) Put the trigonal boron nitride powder into a ball mill jar, pour in nitrogen gas as a protective gas, and ball mill for 10 hours at room temperature with a rotation speed of 700 r / min to obtain two-dimensional boron nitride.

[0042] (4) Fully mix two-dimensional boron nitride powder with a mass ratio of 100:5:5:7, lithium nitride, titanium nitride, and aluminum nitride powder, and press it into a cylindrical shape.

[0043] (5) Put it into the top press, and process under high temperature and high pressure, the temperature is 1400°C, the pressure is 4.0GPa, and the time is 5min.

[0044] (6) Take out the product, and use ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com