Method for separating straight-chain olefins from alkyl alkene containing material flow

A technology for straight-chain olefin and alkene streams, which can be used in adsorption purification/separation, distillation purification/separation, chemical change purification/separation, etc. High efficiency, high purity and low energy consumption

Inactive Publication Date: 2019-03-22

INNER MONGOLIA YITAI COAL BASED NEW MATERIALS RES INST CO LTD

View PDF13 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the route of this process is relatively complicated, and the operation energy consumption is high, resulting in very high investment and operating costs, and this technology can only separate C6 and C8 components, and cannot separate components with high carbon numbers.

[0009] The separation process in the above technical documents all adopts the traditional extractive distillation process. Since the difference between the boiling points of α-olefins and impurities (isomeric olefins) is extremely small, the cost of separation by extractive distillation process is very high, the amount of solvent used is large and the recovery is difficult. Does not meet the needs of current social development

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

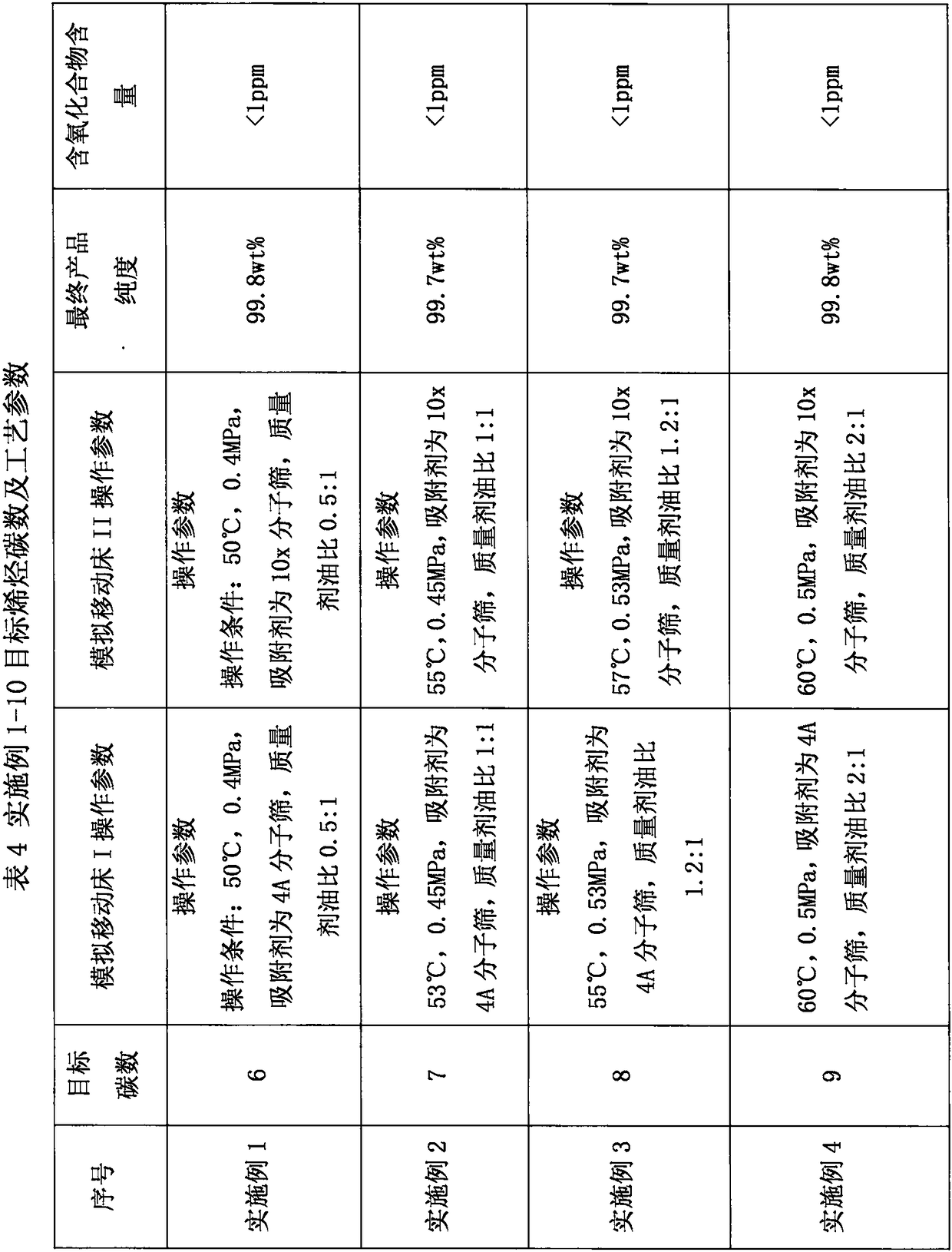

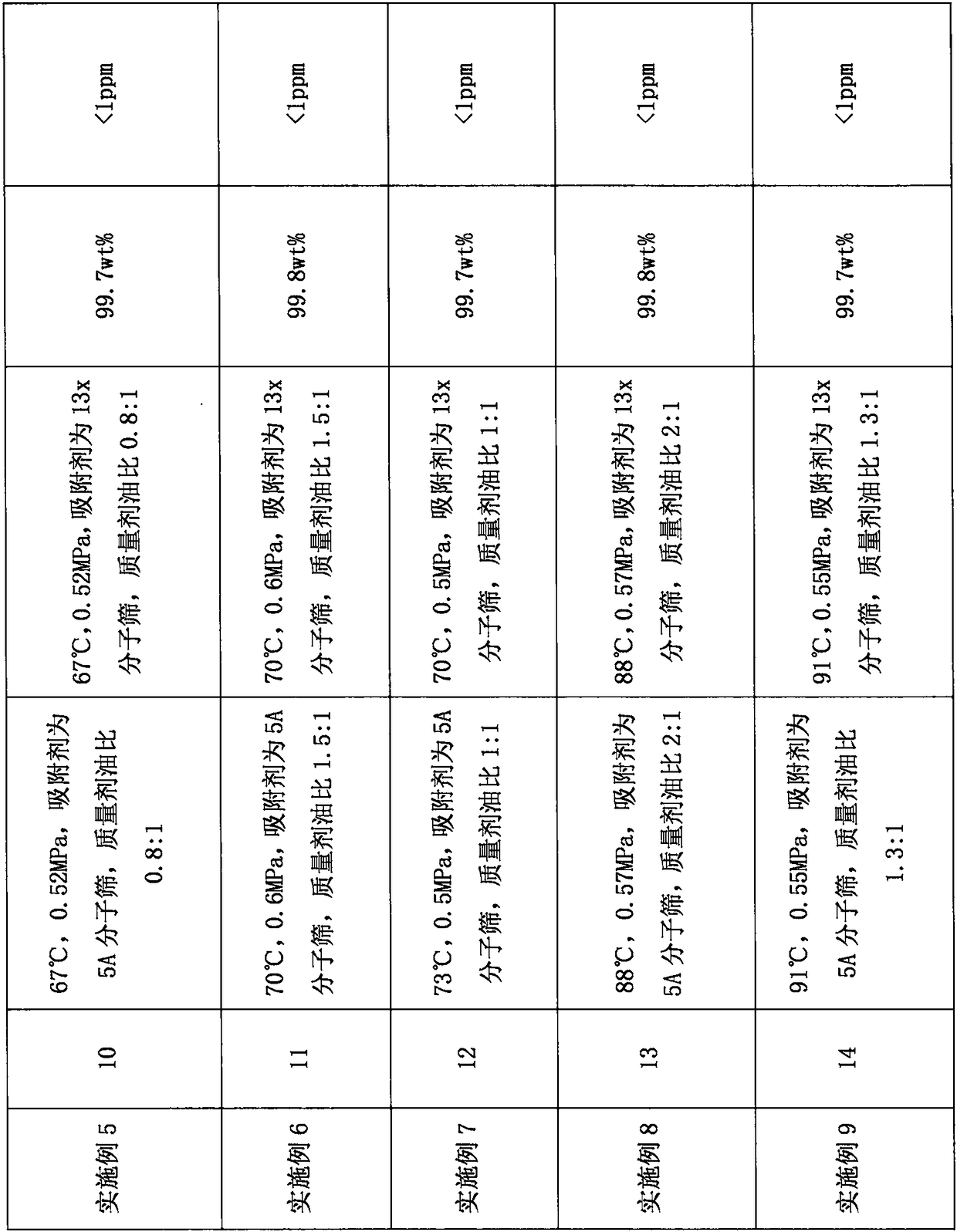

Embodiment 1-11

[0062] The processing methods of Examples 1-11 are basically the same, but the operating parameters are slightly different, and the relevant step parameters are shown in Table 4.

[0063]

[0064]

[0065]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

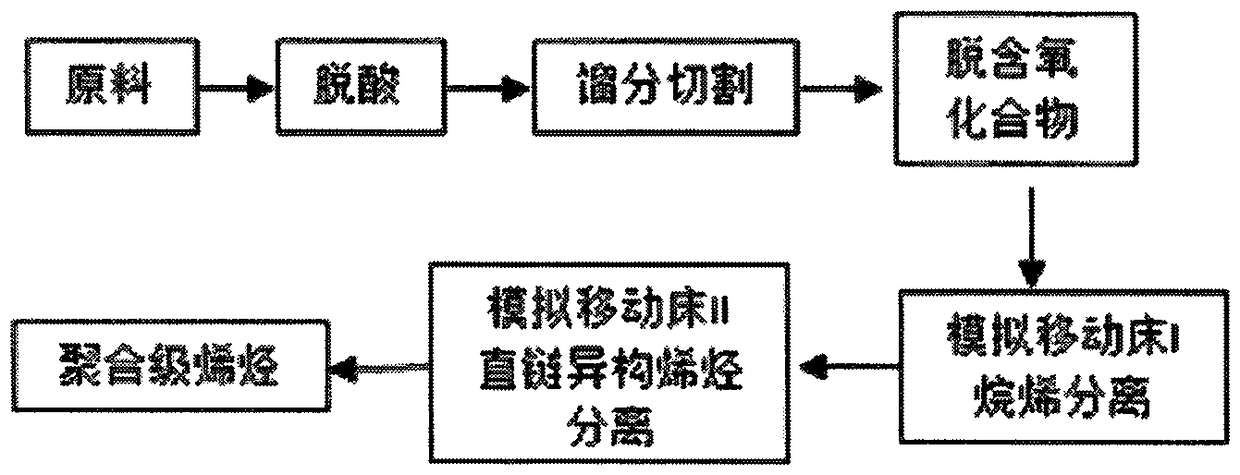

The invention provides a method for separating straight-chain olefins from alkyl alkene containing material flows. The method comprises the steps that coal based fischer-tropsch synthetic oil is usedas raw materials; the range of the target olefin carbon number is 4 to 18; the raw materials are subjected to the steps of deacidification, fraction cutting, oxygenated chemical removal, alkyl alkeneseparation, isomer separation and absorption drying treatment; a polymer grade straight-chain olefin product is obtained. Compared with the traditional rectification and extraction process, the methodhas the advantages that the product purity is high; the yield is high; the energy consumption is low; the production cost is obviously reduced.

Description

technical field [0001] The invention relates to a method for separating linear olefins from a stream containing alkanes, in particular to a method for separating linear olefins by means of a simulated moving bed. Background technique [0002] Fischer-Tropsch synthetic oil products contain a large amount of valuable chemical raw materials - olefins, which are key raw materials for the production of other fine chemical products and have an extremely significant impact on their downstream industries. [0003] At present, domestic and foreign follow-up processing methods for Fischer-Tropsch synthetic oil products mainly focus on distillation and rectification. [0004] Patents US7217852 and US7294253 proposed a distillation method of Fischer-Tropsch synthetic oil and the middle distillate obtained by distillation. The middle distillate contains methyl, ethyl, propyl and other branched chains, and C9~C16 components account for the total More than 90% of the distillate oil, the m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): C07C7/148C07C7/04C07C7/08C07C7/13

Inventor 钱震武靖为李俊诚张晶泉菅青娥张晓龙高源邬学霆陈浩庭

Owner INNER MONGOLIA YITAI COAL BASED NEW MATERIALS RES INST CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap