Straight-chain olefin production method capable of being monitored on line

A technology of linear olefins and production methods, which is applied in the processing of hydrocarbon oil, instruments, measuring devices, etc. It can solve the problems of small application range of detection samples, large deviation of olefin detection repeatability and reproducibility, and achieve product quality control , to achieve rapid response and reduce the effect of the pre-processing process

Pending Publication Date: 2020-09-11

INNER MONGOLIA YITAI COAL BASED NEW MATERIALS RES INST CO LTD

View PDF13 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method uses near-infrared spectroscopy to detect gasoline online in the pipeline, and the scope of application of the detection sample is small, and the repeatability and reproducibility of olefin detection have large deviations

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-11

[0107] The treatment methods of Examples 1-11 are basically the same, but the operating parameters are slightly different, and the relevant step parameters are shown in Table 4.

[0108] Table 4 embodiment 1-10 target olefin carbon number and process parameters

[0109]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

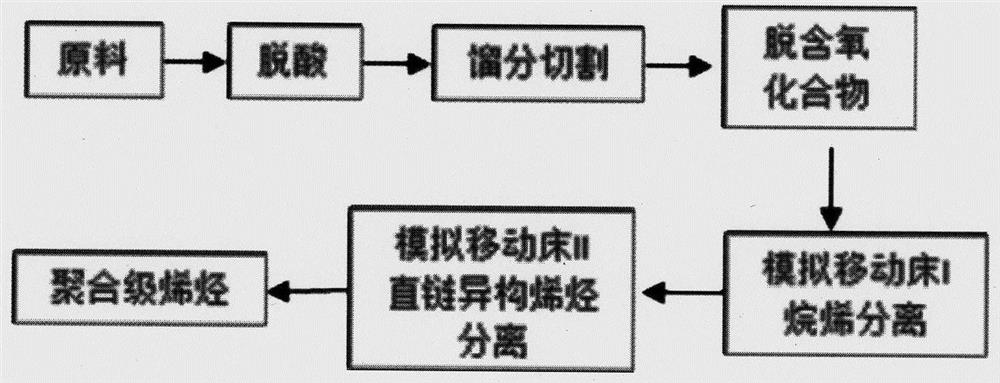

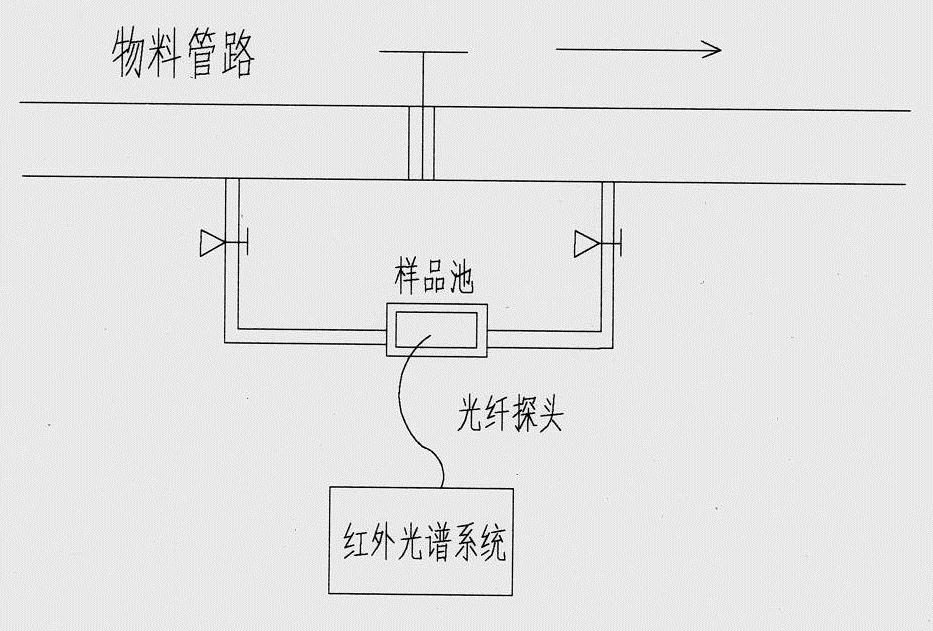

The invention relates to a straight-chain olefin production method capable of being monitored on line. Coal-based Fischer-Tropsch synthetic oil serving as a raw material undergoes deacidification, fraction cutting, oxygen-containing compound removal, alkene separation and isomer separation so as to obtain a polymer-grade olefin product with the olefin carbon number N ranging from 4 to 18; and in the production process, the contents of olefin, alkane and alkyne in the raw material are measured in real time by adopting an online mid-infrared spectrometer, and the operation conditions of each process step are adjusted in real time according to the detection result. The method can be used for producing the straight-chain olefin with high efficiency, low energy consumption, high response speedand high product purity.

Description

technical field [0001] The invention relates to a production method of linear olefins capable of on-line monitoring, in particular to a production method for real-time determination of the content of olefins, alkanes and alkynes and corresponding adjustment of operating conditions. Background technique [0002] Fischer-Tropsch synthetic oil products contain a large amount of valuable chemical raw materials - olefins, which are key raw materials for the production of other fine chemical products and have an extremely significant impact on their downstream industries. [0003] At present, domestic and foreign follow-up processing methods for Fischer-Tropsch synthetic oil products mainly focus on distillation and rectification. [0004] Patents US7217852 and US7294253 proposed a distillation method for Fischer-Tropsch synthetic oil and the middle distillate oil obtained by distillation. The middle distillate oil contains branched chains such as methyl, ethyl, and propyl groups,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10G57/00G01N21/3577

CPCC10G57/00G01N21/3577G01N21/274

Inventor 李俊诚钱震张晓龙武靖为高源邬学霆陈浩庭

Owner INNER MONGOLIA YITAI COAL BASED NEW MATERIALS RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com