Method for preparing perfluoroalkyl iodine through catalytic distillation telomerization

A perfluoroalkyl iodide and catalytic distillation technology, which is applied in chemical instruments and methods, preparation of halogenated hydrocarbons, chemical industry, etc., can solve problems affecting the normal operation of industrial devices, catalysts cannot be recycled, and the content of hydrogen-containing by-products is large. problems, to achieve the effect of avoiding hydrogen-containing by-products, avoiding difficulties in solid-liquid separation, and good product composition distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

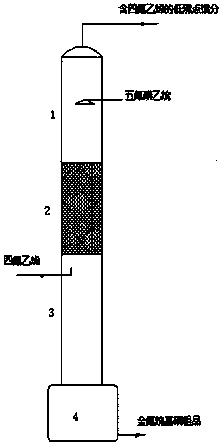

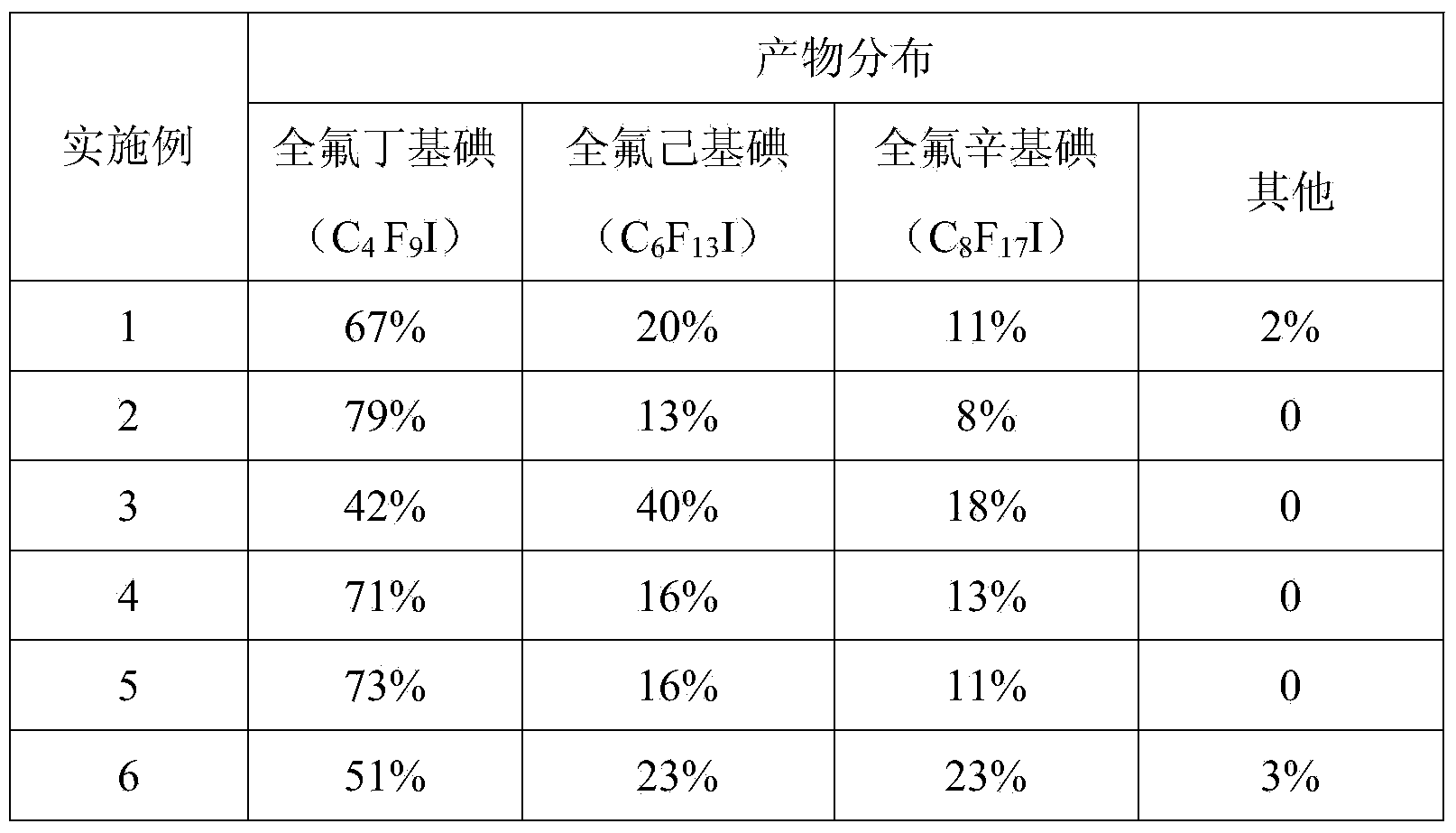

[0027] The inner diameter of the catalytic distillation tower is φ1000mm, the reaction section 2 is divided into three sections, and each section is filled with phosphor bronze wire mesh corrugated packing Xiangshi Huaxing Chemical Equipment Packing Co., Ltd. Production, model 125, specific surface area 125m 2 / m 3 , according to the mass percentage, the composition is: 2% tin, 0.4% phosphorus, 0.08% lead, and the rest is copper) 2m high, C 2 f 5 I is continuously added from the rectifying section 1 at the upper part of the reaction section 2, and gas-phase tetrafluoroethylene is continuously added from the stripping section 3 at the lower part of the reaction section 2. The reaction conditions are: C 2 f 5 The molar ratio of I and tetrafluoroethylene is 1:5; the reaction pressure is 1.0 MPa; the temperature of the reaction section is 70° C., the low-boiling fraction containing tetrafluoroethylene is extracted from the top of the tower, and the perfluoroalkyl iodide crude...

Embodiment 2

[0029] The inner diameter of the catalytic distillation tower is φ1000mm, the reaction section 2 is divided into five sections, and each section is filled with phosphor bronze wire mesh corrugated packing Xiangshi Huaxing Chemical Equipment Packing Co., Ltd. Production, model 250, specific surface area 250m 2 / m 3 , according to the mass percentage content: tin 3%, phosphorus 0.3%, lead 0.05%, the rest is copper) 1m high, C 2 f 5 I is continuously added from the rectifying section 1 at the upper part of the reaction section 2, and gas-phase tetrafluoroethylene is continuously added from the stripping section 3 at the lower part of the reaction section 2. The reaction conditions are: C 2 f 5 The molar ratio of I and tetrafluoroethylene is 1:3; the reaction pressure is 0.8MPa; the temperature of the reaction section is 80° C., the low-boiling fraction containing tetrafluoroethylene is extracted from the tower top, and the perfluoroalkyl iodide crude product is continuously ...

Embodiment 3

[0031] The inner diameter of the catalytic distillation tower is φ1000mm, the reaction section 2 is divided into one section, and each section is filled with phosphor bronze wire mesh corrugated packing Xiangshi Huaxing Chemical Equipment Packing Co., Ltd. Production, model 500, specific surface area 500m 2 / m 3 , according to the mass percentage, the composition is: 4% tin, 0.2% phosphorus, 0.1% lead, and the rest is copper) 5m high, C 2 f 5 I is continuously added from the rectifying section 1 at the upper part of the reaction section 2, and gas-phase tetrafluoroethylene is continuously added from the stripping section 3 at the lower part of the reaction section 2. The reaction conditions are: C 2 f 5The molar ratio of I and tetrafluoroethylene is 1:7; the reaction pressure is 0.6MPa; the temperature of the reaction section is 85° C., the low-boiling fraction containing tetrafluoroethylene is extracted from the tower top, and the perfluoroalkyl iodide crude product is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com