A kind of method that utilizes salicylic acid residue to decompose and recover sodium phenolate

A technology of salicylic acid and sodium phenolate, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of high cracking temperature and low yield of phenol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

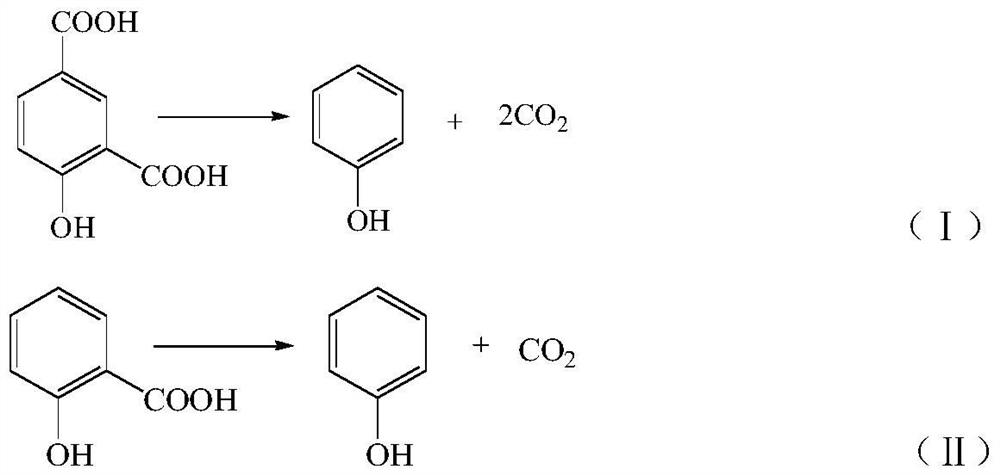

[0032] The mass composition of salicylic acid residues: 32.3% of water, 48.1% of salicylic acid, 10.6% of 4-hydroxyisophthalic acid, 0.8% of p-hydroxybenzoic acid, 8.2% of inorganic salts and other components.

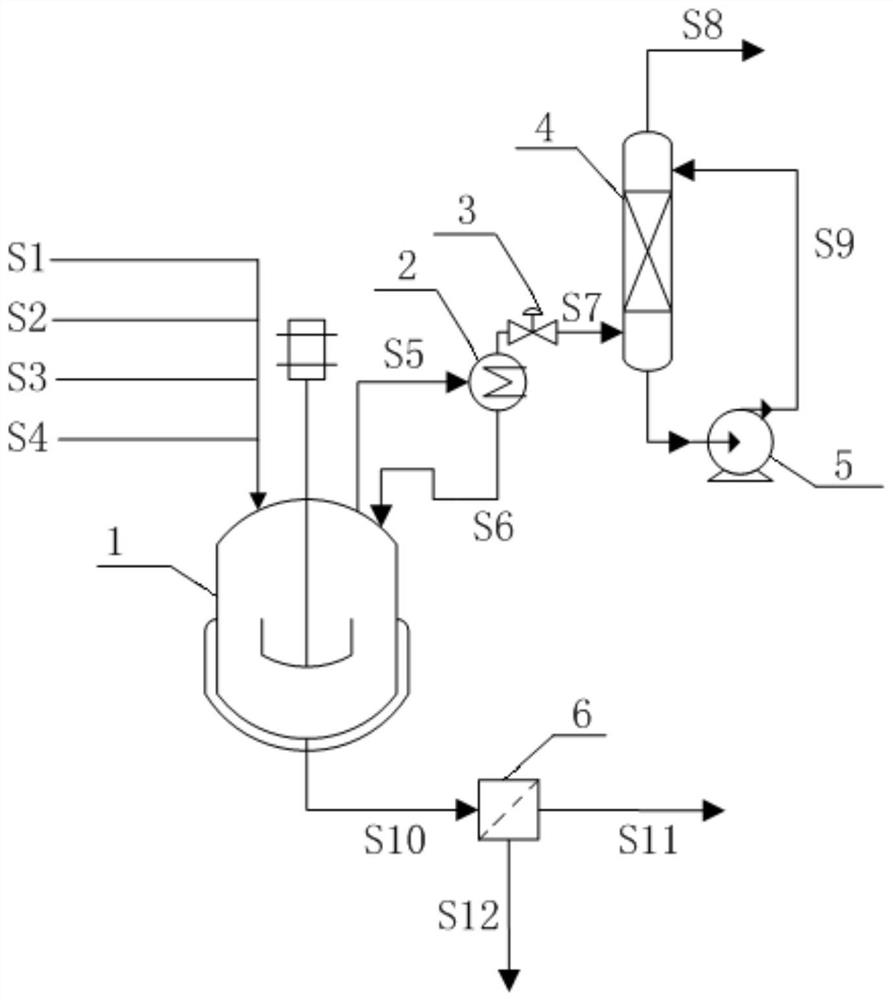

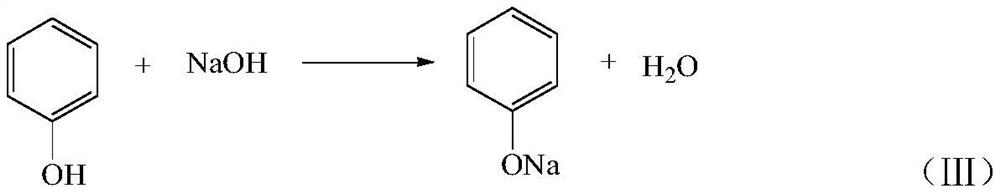

[0033] Add 5000kg of reaction medium water (S1) in the reactor 1. After starting the stirring, add 2000kg of salicylic acid residue (S2), and the ratio of residue to water is 0.4:1. Seal the feeding port, after the nitrogen replacement is qualified, close the pressure regulating valve 3 on the exhaust line, start heating the material in the reactor 1, set the reaction temperature to 180°C (at this temperature, the saturated vapor pressure of water is 1.02MPa), and the condenser 2 To cool the water, open the washing water pump 5 to feed the washing tower 4 with washing water (S9), and the washing water is recycled. When the pressure rises to 1.3MPa, the opening pressure regulating valve 3 is set to automatic, and the pressure setting value is 1.3MPa. The reaction exha...

Embodiment 2

[0035] Salicylic acid residue quality composition, the proportioning of residue and water is the same as Example 1. The reaction temperature is set at 200° C. (the saturated vapor pressure of water at this temperature is 1.55 MPa), and the reaction pressure set value is 1.8 MPa. After 150 minutes of reaction, the exhaust gas was reduced, the pressure regulating valve 3 was automatically closed, and the reaction was completed. Other operations are the same as Example 1. This reaction obtains 7200kg of sodium phenate solution, the sodium phenate content of sampling analysis is 13.1%, and the calculated phenol yield is 98.2%.

Embodiment 3

[0037] The salicylic acid residue quality composition is the same as Example 1. The ratio of residue to water is 0.3:1, 1500kg and 5000kg respectively. The reaction temperature is set at 210° C. (the saturated vapor pressure of water at this temperature is 1.91 MPa), and the reaction pressure is set at 2.3 MPa. After 70 minutes of reaction, the exhaust gas was reduced, the pressure regulating valve 3 was automatically closed, and the reaction was completed. Add about 550kg of 50% sodium hydroxide solution (S3), the pH is 12.6, and then add 20kg of activated carbon (S4). Other operations are the same as Example 1. This reaction obtains about 6700kg of sodium phenate solution, and the sodium phenate content of sampling analysis is 10.5%, and the calculated phenol yield is 97.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com