Preparation method for polymercaptan compound containing 1,3,5-trithian structure and application thereof

A technology of polythiol compound and trithiane, which is applied in the field of optical materials, can solve the problems that catalysts cannot be reused, does not meet environmental protection requirements, and has a large output of waste acid, and achieves good heat resistance, high refractive index, and no three wastes. The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

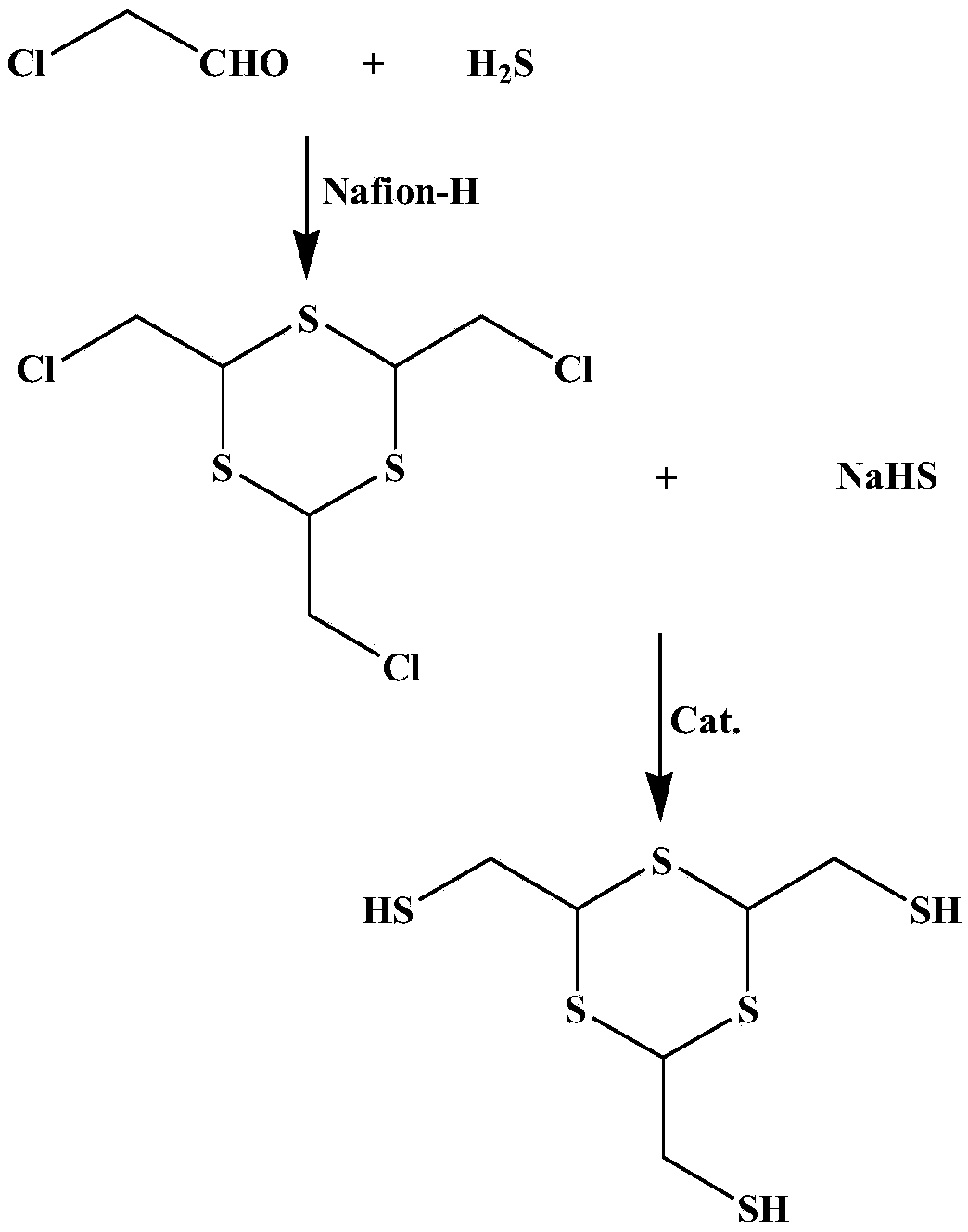

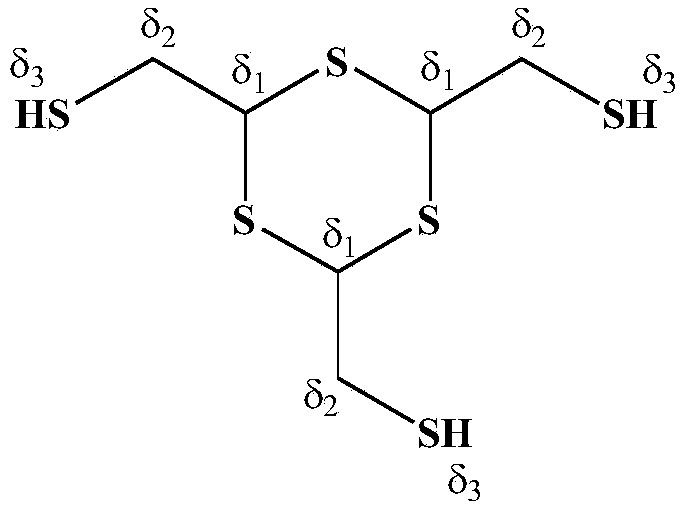

[0026] The invention provides a method for preparing a polythiol compound containing a 1,3,5-trithiane structure, comprising the following steps:

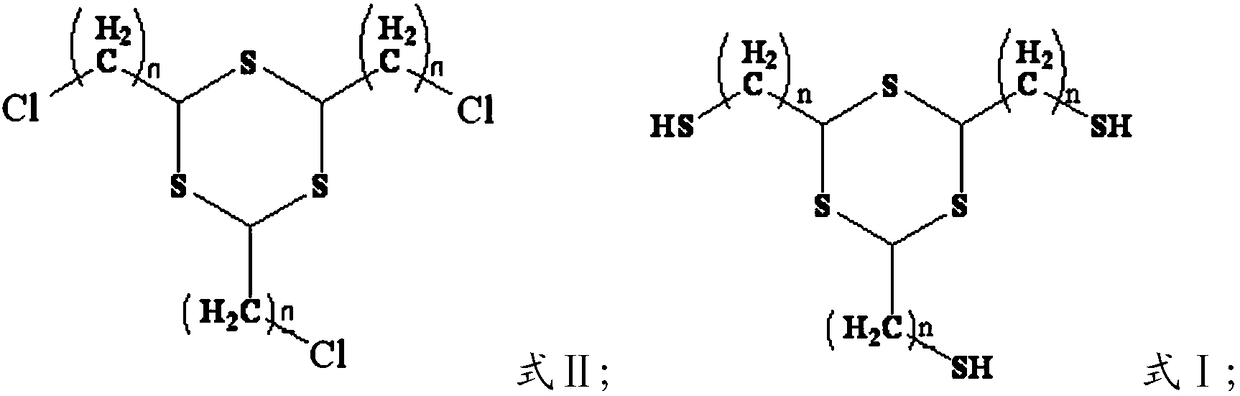

[0027] Under the phase transfer catalyst, react 2,4,6-trichloroalkyl-1,3,5-trithiane with the structure of formula II with sodium hydrosulfide to obtain the 1,3,5-containing compound with the structure of formula I -polythiol compound of trithiane structure;

[0028]

[0029] Wherein, the value of n is 1 or 2.

[0030] In this method, only by reacting 2,4,6-trichloroalkyl-1,3,5-trithiane with sodium hydrosulfide, a 1,3,5-trithiane-containing structure having the structure of formula I can be obtained. The polythiol compound, the method is simple, no three wastes are discharged, it meets the requirements of environmental protection, and the reaction conversion rate is high. In addition, it also has high selectivity, high economic utilization rate of atoms, and the prepared products have high refractive index and high Abbe value...

Embodiment 1

[0060] The strong acid type catalyst Nafion-H was prepared with reference to the preparation method recorded in the Chinese patent whose application number is CN2014102780510A.

[0061]The prepared mesoporous material supported strong acid catalyst Nafion-H was installed in a tubular reactor, and the ClCH with a mass fraction of 35% was accurately measured 2 CHO aqueous solution 200g and H 2 S gas is passed into the reactor at the same time for reaction, and the temperature is controlled at 50-52°C throughout the process. After the reaction is completed, stop the flow of H 2 S gas, after filtering the reaction liquid, 49.35 g of 2,4,6-trichloromethyl-1,3,5-trithiane solid can be obtained.

[0062] Weigh 42.53g of 2,4,6-trichloromethyl-1,3,5-trithiane solid and dissolve it in methanol solution to obtain 2,4,6-trichloromethyl-1,4,6-trichloromethyl- 1,3,5-trithiane solution, pour it into the autoclave, add 0.013g of tetrabutylammonium bromide catalyst and 131.48g of NaHS soluti...

Embodiment 2

[0065] The strong acid type catalyst Nafion-H was prepared with reference to the preparation method recorded in the Chinese patent whose application number is CN2014102780510A.

[0066] The prepared mesoporous material supported strong acid catalyst Nafion-H was installed in the tubular reactor, and the ClCH with a mass fraction of 32% was accurately measured 2 CHO aqueous solution 200g and H 2 S gas is passed into the reactor at the same time for reaction, and the temperature is controlled at 50-52°C throughout the process. After the reaction is completed, stop the flow of H 2 S gas, after filtering the reaction liquid, 55.37 g of 2,4,6-trichloromethyl-1,3,5-trithiane solid can be obtained.

[0067] Weigh 42.53g of 2,4,6-trichloromethyl-1,3,5-trithiane solid and dissolve it in methanol solution to obtain 2,4,6-trichloromethyl-1,4,6-trichloromethyl- 1,3,5-trithiane solution, pour it into the autoclave, add 0.013g of tetrabutylammonium bromide catalyst and 100.08g of NaHS sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com