A kind of low-temperature curable polyester resin and its preparation method and application

A polyester resin, curing technology, applied in polyester coatings, powder coatings, coatings, etc., can solve the problem of high energy consumption, achieve high activity, reduce energy consumption, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

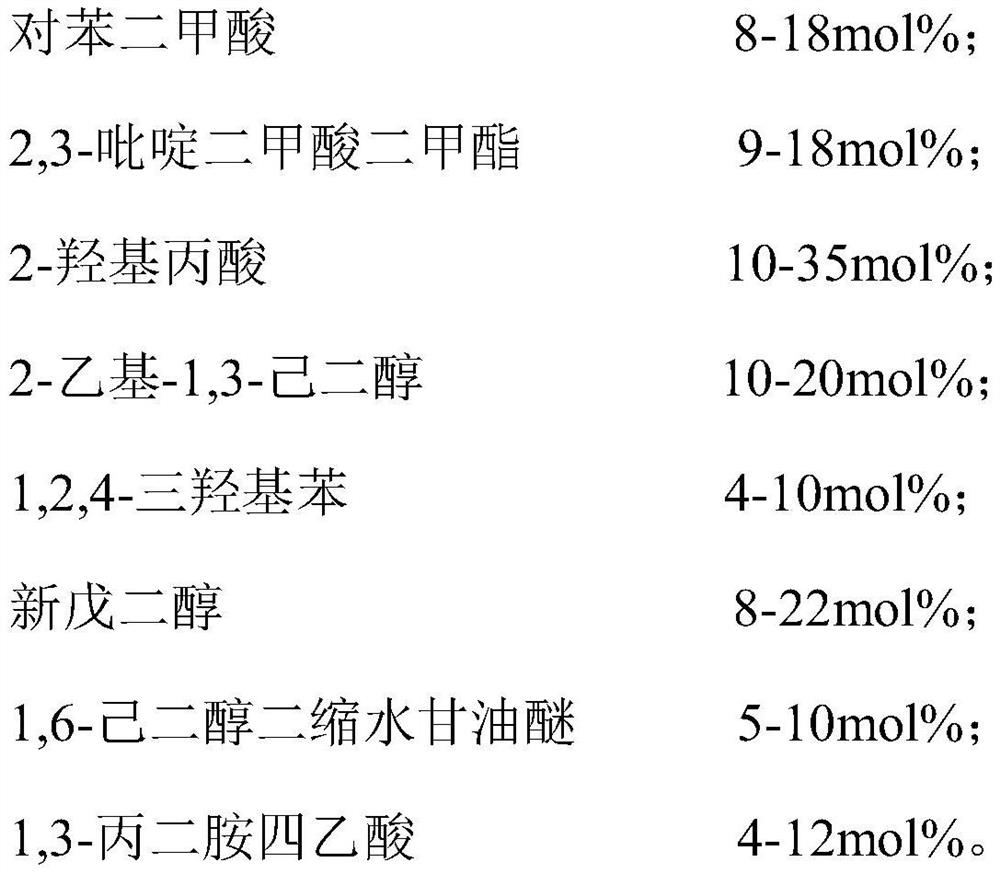

[0024] The low-temperature curing polyester resin described in this embodiment, based on the total amount of the polyester resin, its preparation raw materials include the following molar amounts of raw material components:

[0025]

[0026] The preparation method of the low-temperature curing type polyester resin described in the present embodiment comprises the following steps:

[0027] (1) Mix the terephthalic acid and dimethyl 2,3-pyridinedicarboxylate in the formulation amount, and control the temperature to be lower than 130°C for heating and melting;

[0028] (2) Add the 2-ethyl-1,3-hexanediol, neopentyl glycol, and 1,6-hexanediol diglycidyl ether in the formula amount to the above-mentioned mixed material, and add the selected amount of the The above-mentioned catalyst, under the protection of nitrogen, gradually raised the temperature to 200°C for reaction; then added the 2-hydroxypropionic acid and 1,2,4-trihydroxybenzene in the formula amount, slowly raised the t...

Embodiment 2

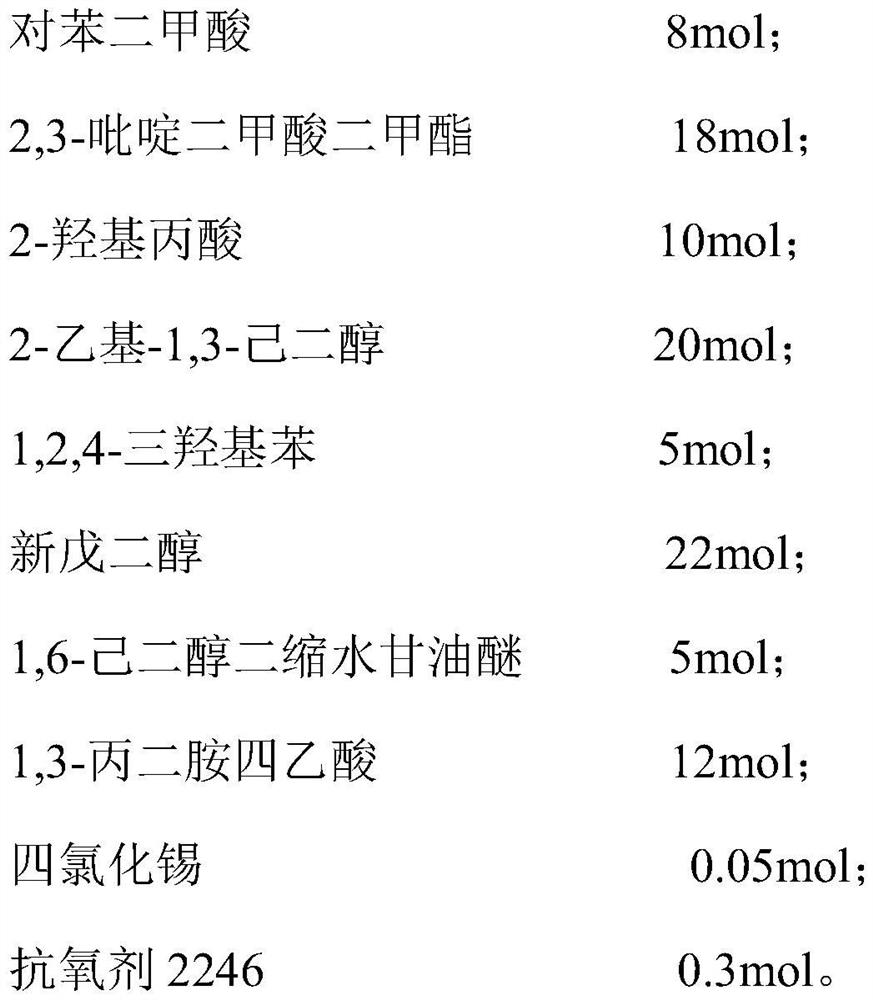

[0033] The low-temperature curing polyester resin described in this embodiment, based on the total amount of the polyester resin, its preparation raw materials include the following molar amounts of raw material components:

[0034]

[0035] The preparation method of the low-temperature curing type polyester resin described in the present embodiment comprises the following steps:

[0036] (1) Mix the terephthalic acid and dimethyl 2,3-pyridinedicarboxylate in the formulation amount, and control the temperature to be lower than 130°C for heating and melting;

[0037] (2) Add the described 2-ethyl-1,3-hexanediol, neopentyl glycol, 1,6-hexanediol diglycidyl ether of formula amount to above-mentioned mixture material, and add the selected amount of all The above catalyst, under the protection of nitrogen, gradually raised the temperature to 190°C for reaction; then added the formula amount of 2-hydroxypropionic acid and 1,2,4-trihydroxybenzene, slowly raised the temperature and...

Embodiment 3

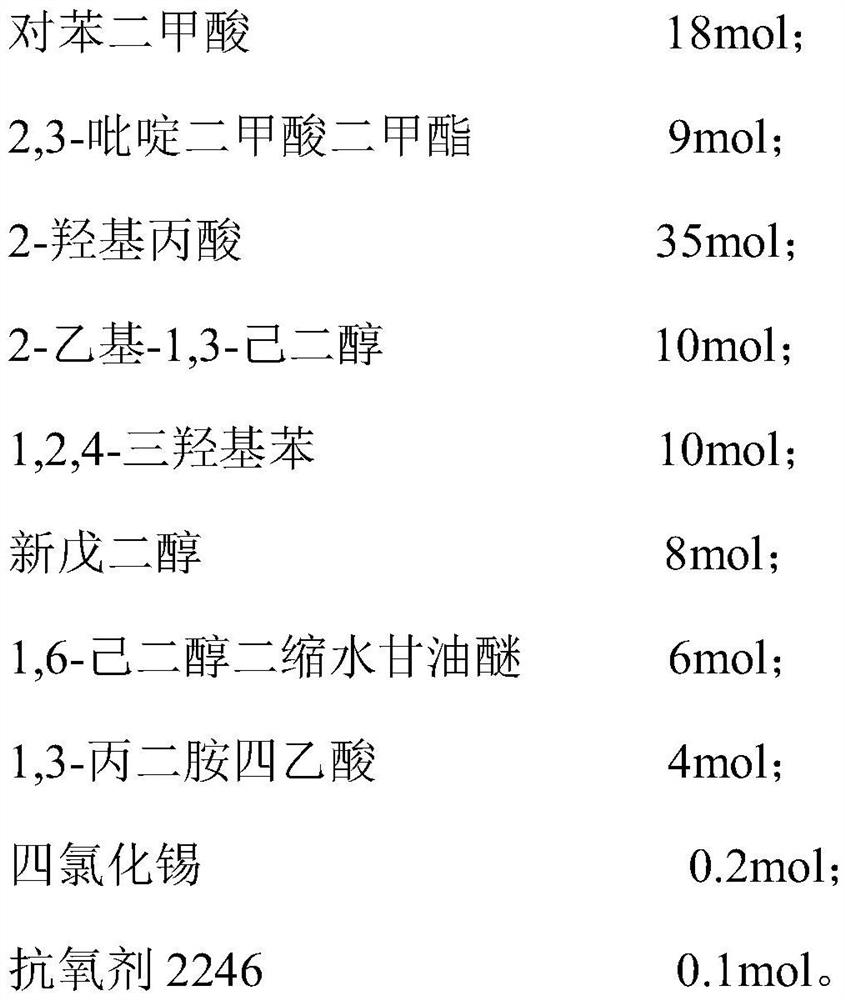

[0042] The low-temperature curing polyester resin described in this embodiment, based on the total amount of the polyester resin, its preparation raw materials include the following molar amounts of raw material components:

[0043]

[0044]

[0045] The preparation method of the low-temperature curing type polyester resin described in the present embodiment comprises the following steps:

[0046] (1) Mix the terephthalic acid and dimethyl 2,3-pyridinedicarboxylate in the formulation amount, and control the temperature to be lower than 130°C for heating and melting;

[0047] (2) Add the described 2-ethyl-1,3-hexanediol, androstenediol, neopentyl glycol, 1,6-hexanediol diglycidyl ether of formulation amount in the above-mentioned mixed material, and Add a selected amount of the catalyst, under the protection of nitrogen, gradually raise the temperature to 195°C for reaction; then add the formula amount of 2-hydroxypropionic acid and 1,2,4-trihydroxybenzene, slowly raise t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com