Talcum powder master batch and preparation method thereof

A technology of talcum powder masterbatch and polyolefin resin, which is applied in the field of talc powder masterbatch and its preparation, can solve the problems of high cost, low scratch-resistant efficiency, low odor, etc., and achieve improved rigidity, improved scratch resistance, and reduced The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

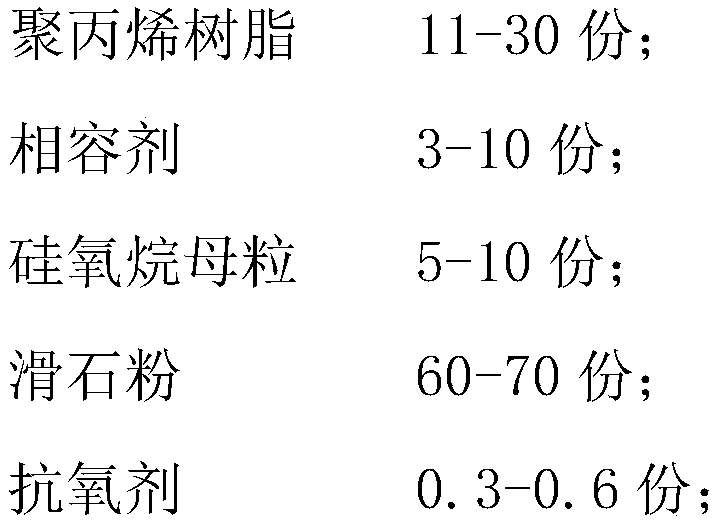

[0039] A kind of talcum powder masterbatch, it comprises following component by raw material weight part:

[0040] 16 parts of polypropylene resin;

[0041] 6 parts of compatibilizer;

[0042] 8 parts of silicone masterbatch;

[0043] 70 parts of talcum powder;

[0044] 0.4 part of antioxidant.

[0045] The compatibilizer is composed of polyolefin resin and dialkyl-terminated amino silicone oil in a weight ratio of 5:1.

[0046] Preparation method: Step 1: Add polypropylene resin, compatibilizer, and siloxane masterbatch to the internal mixer according to the weight of the raw materials and stir for 1-2 minutes, then add talcum powder and antioxidant for melting and banburying at 180°C , so that the talc powder and the carrier are fully mixed to obtain a premix; the above premix is fed into a twin-screw granulator through forced feeding, melted and extruded at an extrusion temperature of 150-200°C, and air-cooled and pelletized . Step 2: Put the pellets prepared in Ste...

Embodiment 2

[0049] A kind of talcum powder masterbatch, it comprises following component by raw material weight part:

[0050] 30 parts of polypropylene resin;

[0051] 3 parts of compatibilizer

[0052] 5 parts of silicone masterbatch;

[0053] 60 parts of talcum powder;

[0054] 0.3 parts of antioxidant.

[0055] The compatibilizer is composed of polyolefin resin and dialkyl-terminated amino silicone oil in a weight ratio of 3:1.

[0056]Preparation method: Step 1: Add polypropylene resin, compatibilizer, and siloxane masterbatch to the internal mixer according to the weight of the raw materials and stir for 1-2 minutes, then add talcum powder and antioxidant for melting and banburying at 180°C , so that the talc powder and the carrier are fully mixed evenly to obtain a premix; the above premix is fed into a twin-screw granulator through forced feeding, melted and extruded at an extrusion temperature of 150-200 ° C, air-cooled and pelletized . Step 2: Put the pellets in Step 1 i...

Embodiment 3

[0059] A kind of talcum powder masterbatch, it comprises following component by raw material weight part:

[0060] 11 parts of polypropylene resin;

[0061] 10 parts of compatibilizer;

[0062] 10 parts of silicone masterbatch;

[0063] 70 parts of talcum powder;

[0064] 0.6 part of antioxidant.

[0065] The compatibilizer is composed of polyolefin resin and dialkyl-terminated amino silicone oil in a weight ratio of 3.5:1.

[0066] Preparation method: Step 1: Add polypropylene resin, compatibilizer, and siloxane masterbatch to the internal mixer according to the weight of the raw materials and stir for 1-2 minutes, then add talcum powder and antioxidant for melting and banburying at 180°C , so that the talc powder and the carrier are fully mixed evenly to obtain a premix; the above premix is fed into a twin-screw granulator through forced feeding, melted and extruded at an extrusion temperature of 150-200 ° C, air-cooled and pelletized . Step 2: Put the pellets in Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com