Tea stain detergent and preparation method thereof

A cleaning agent and tea scale technology, applied in the field of cleaning agents, can solve the problems of poor stability of sodium percarbonate, unsatisfactory tea scale removal effect, and difficulty in effectively removing tea scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

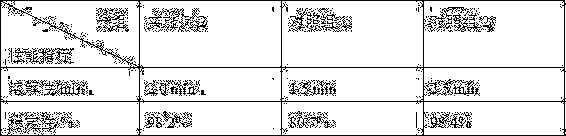

Image

Examples

Embodiment 1

[0018] A tea stain cleaner, the main component of the tea stain cleaner is sodium percarbonate, the average particle diameter of the sodium percarbonate particles is 300 μm, the surface of the sodium percarbonate particles is provided with a coating layer, the The coating is made from a mixture of citric acid and sodium citrate. The preparation method of the tea stain cleaner is as follows: respectively take citric acid and sodium citrate and dissolve them in deionized water to obtain a mixed solution of citric acid and sodium citrate. In the mixed solution, the total mass of citric acid and sodium citrate Ratio of 35%, then spray sodium percarbonate particles with the mixed solution in the fluidized bed, after spraying is completed, dry at 55°C to get final product; wherein, the mass ratio of citric acid and sodium citrate is 2:5 .

Embodiment 2

[0020] A tea stain cleaner, the main component of the tea stain cleaner is sodium percarbonate, the average particle diameter of the sodium percarbonate particles is 500 μm, the surface of the sodium percarbonate particles is provided with a coating layer, the The coating is made from a mixture of citric acid and sodium citrate. The preparation method of the tea stain cleaner is as follows: respectively take citric acid and sodium citrate and dissolve them in deionized water to obtain a mixed solution of citric acid and sodium citrate. In the mixed solution, the total mass of citric acid and sodium citrate Ratio is 40%, then spray sodium percarbonate particles with the mixed solution in the fluidized bed, after spraying is completed, dry at 60°C to get final product; wherein, the mass ratio of citric acid and sodium citrate is 2:6 .

Embodiment 3

[0022] A tea stain cleaner, the main component of the tea stain cleaner is sodium percarbonate, the average particle diameter of the sodium percarbonate particles is 800 μm, the surface of the sodium percarbonate particles is provided with a coating layer, the The coating is made from a mixture of citric acid and sodium citrate. The preparation method of the tea stain cleaner is as follows: respectively take citric acid and sodium citrate and dissolve them in deionized water to obtain a mixed solution of citric acid and sodium citrate. In the mixed solution, the total mass of citric acid and sodium citrate Ratio is 50%, then spray sodium percarbonate particles with the mixed solution in the fluidized bed, after spraying is completed, dry at 70°C to get final product; Wherein, the mass ratio of the citric acid and sodium citrate is 2: 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com