80 kg-grade low-carbon equivalent low-crack sensitivity large-thickness hydroelectric steel and manufacturing method thereof

A manufacturing method and carbon equivalent technology, applied in the field of metal materials, can solve problems such as failure to meet requirements, failure to guarantee low-temperature toughness reserves, failure to meet the requirements of high-strength steel, etc., and achieve the effect of improving the yield and excellent tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

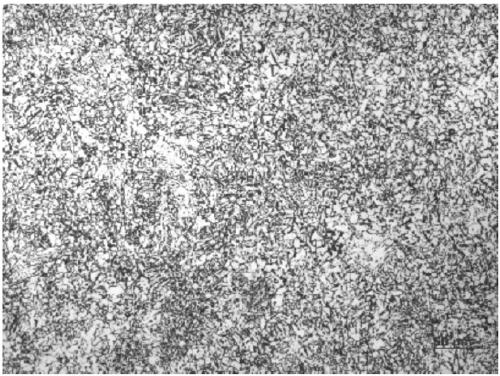

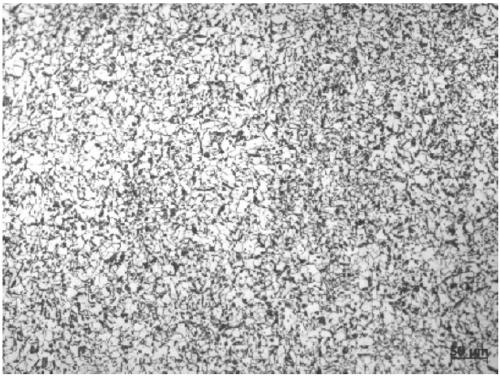

Image

Examples

Embodiment 1

[0038] The thickness of the hydropower steel plate designed in Example 1 is 150mm.

[0039] The production process of large thickness hydropower steel plate is as follows:

[0040] Allocation of smelting raw materials according to the chemical composition of the above-mentioned large-thickness hydropower steel plate, followed by KR molten iron pretreatment→converter smelting→LF refining→RH refining→continuous casting→slow cooling of blank hood→heating→high pressure water descaling→controlled rolling→hot straightening→ Steel plate stack slow cooling or cover slow cooling → quenching and tempering.

[0041] The specific process of heating, rolling and controlled cooling is: heating the continuous casting slab to 1220-1280 ℃ for 3 hours, descaling with high-pressure water after being released from the furnace, and performing two-stage controlled rolling (rough rolling and finishing rolling). The first stage of controlled rolling (i.e. rough rolling) is 1040℃~1080℃, the second st...

Embodiment 1

[0043] For example 1: water quenching of the steel plate with a quenching machine: the heating temperature is 900° C., and the time in the furnace is 230 minutes.

[0044] Temper in a continuous furnace at 630°C, stay in the furnace for 630 minutes, and cool in air after taking out the furnace.

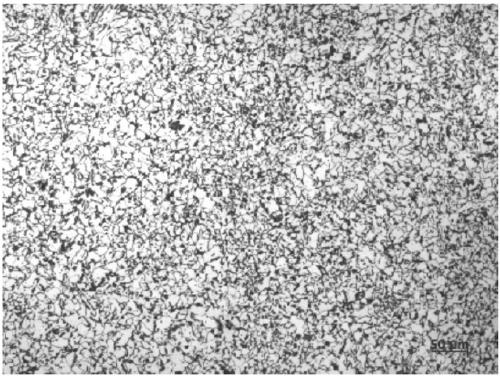

Embodiment 2

[0045] For Example 2: water quenching of the steel plate with a quenching machine: heating temperature 920°C, furnace time 330min.

[0046] Temper in a continuous furnace at 650°C, stay in the furnace for 420 minutes, and air-cool after taking out the furnace.

[0047] The finished steel plate produced by the above manufacturing process has low carbon equivalent, low crack sensitivity, high strength, and good plasticity and toughness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com