Bionic cultivation method for dendrobium officinale

A technology of Dendrobium officinale and a cultivation method, which is applied in the directions of cultivation, soilless cultivation, botanical equipment and methods, etc., can solve the problems of low polysaccharide content of Dendrobium officinale, difficult to popularize in a large area, uncontrollable environment, etc., and achieves improved growth and survival. rate, improve germination rate, save labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

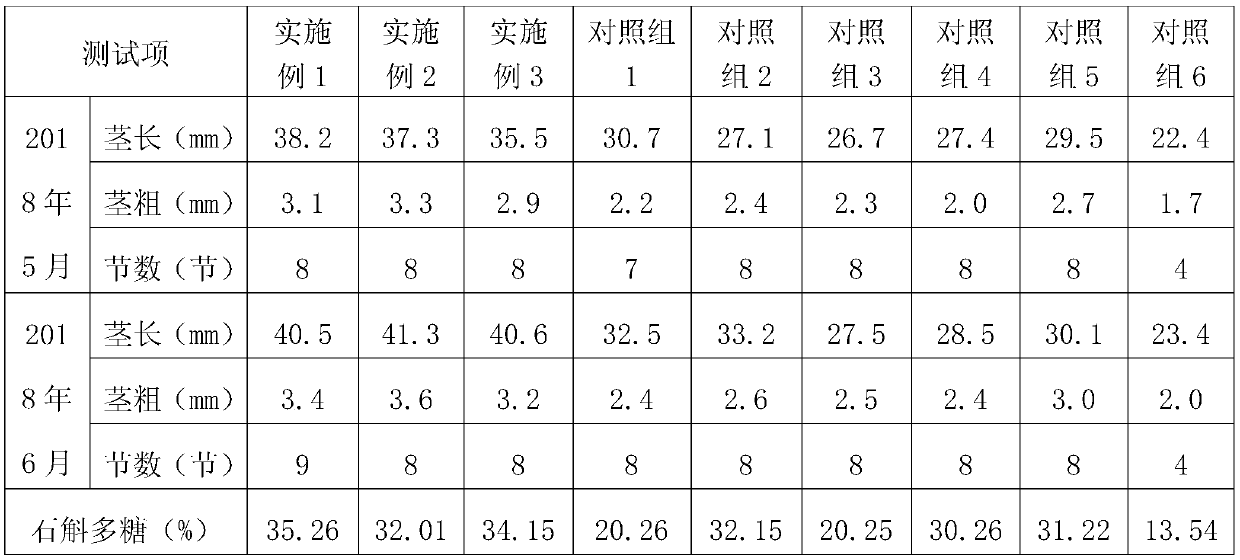

Embodiment 1

[0032] The substrate 5 of this embodiment is composed of the following components by weight: 12 parts of clay, 21 parts of fermented sheep manure, 7 parts of starch, 5 parts of quicklime, and 10 parts of plant enzyme; wherein, the starch is glutinous rice starch; Its preparation method is as follows: after the above-mentioned raw materials are fully mixed, add water and knead while stirring, knead the mixture into a ball, and squeeze it by hand so that water can come out to obtain the matrix 5 of the present application.

[0033] The plant enzyme used in the present embodiment is made from probiotics, Dendrobium officinale root, Dendrobium officinale leaf, kudzu root, pineapple, fir sawdust, sodium selenite, amino acid and sodium alkylbenzene sulfonate, wherein, Dendrobium officinale leaf, Dendrobium officinale root, kudzu root and pineapple are all fresh plants; the preparation method of plant enzyme is as follows:

[0034] (1) Strain expansion and preparation: mix brown suga...

Embodiment 2

[0046] The substrate 5 of the present embodiment is made up of the following components by weight: 18 parts of clay, 27 parts of fermented sheep manure, 17 parts of starch, 15 parts of quicklime, and 17 parts of plant enzyme; wherein, starch is flour and cassava Starch is obtained by mixing the starch at a mass ratio of 1:1; the preparation method is as follows: fully mix the above raw materials, add water and knead while stirring, knead the mixture into a ball, and squeeze it by hand to obtain the matrix 5 of the application.

[0047] The plant enzyme used in the present embodiment is made from probiotics, Dendrobium officinale root, Dendrobium officinale leaf, kudzu root, pineapple, fir sawdust, sodium selenite, amino acid and sodium alkylbenzene sulfonate, wherein, Dendrobium officinale leaf, Dendrobium officinale root, kudzu root and pineapple are all fresh plants; the preparation method of plant enzyme is as follows:

[0048] (1) Strain expansion and preparation: mix brow...

Embodiment 3

[0060] The substrate 5 of the present embodiment is made up of the following components by weight: 16 parts of clay, 23 parts of fermented sheep manure, 12 parts of starch, 8 parts of quicklime, and 14 parts of plant enzyme; wherein, the starch is glutinous rice starch, It is obtained by mixing flour and potato starch at a ratio of 1:1:1; the preparation method is as follows: mix the above-mentioned raw materials thoroughly, add water and knead while stirring, knead the mixture into a ball, and squeeze the water by hand to obtain the matrix 5 of this application .

[0061] The plant enzyme used in the present embodiment is made from probiotics, Dendrobium officinale root, Dendrobium officinale leaf, kudzu root, pineapple, fir sawdust, sodium selenite, amino acid and sodium alkylbenzene sulfonate, wherein, Dendrobium officinale leaf, Dendrobium officinale root, kudzu root and pineapple are all fresh plants; the preparation method of plant enzyme is as follows:

[0062] (1) Str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com