Preparation method for dried tremella

A production method and technology of jade fungus, which are applied in the preservation of fruits/vegetables by dehydration, food science, etc., can solve the problems of natural drying method, such as large land area, affecting the quality of dry products, market circulation enterprise benefits, and increasing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1 A kind of preparation method of dry product jade fungus

[0014] A kind of preparation method of dried jade fungus, concrete steps are as follows:

[0015] 1) Harvesting: stop watering for 3 hours before harvesting, so that the water on the surface of the ears evaporates, and the water content is below 95%. For the mature ear piece with white spores visible on the surface, choose the ear piece with a complete color and white color, and clean the base of the material and other impurities;

[0016] 2) Pre-cooling: Seal and pack the screened ear piece in a ziplock bag, do not compact it hard to affect the shape of the ear, store it in a refrigerator at 0°C-4°C for 2 hours, and carry out pre-cooling treatment;

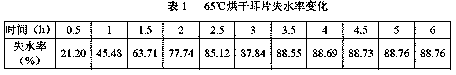

[0017] 3) Drying: Use a fruit and vegetable dryer with a power of 250W, a rated voltage of 220V, and hot air circulation; set the temperature of the dryer to 65°C, and basically reach 40°C after 30 minutes of preheating. Lay the ear pieces evenly in a...

Embodiment 2

[0021] Example 2 The effect of drying temperature on the product of jade fungus

[0022] By setting different temperature gradients, namely 35°C, 45°C, 55°C, 65°C, comparing the color, wet-dry ratio and rehydration rate of dried jade fungus at different temperatures, and optimizing the drying temperature;

[0023] By using the Color Flex by Hunter lab 45 / 0 colorimeter to identify the color of the dry products obtained by drying at different temperatures, it can be seen that with the increase of temperature, the L (lightness), a (red-green), b (yellow blue) shows irregular changes, and there are significant differences among the four temperatures, 65°C △ The highest value indicates that the color properties of dried ear pieces obtained by drying at 65°C are better;

[0024] The analysis of the wet-dry ratio and rehydration rate of jade fungus at different drying temperatures showed that there was no significant difference in the wet-dry ratio and rehydration rate among the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com