Porous-particle composite iron for treating inorganic and organic pollutants in liquid and gas

An organic pollutant, porous technology, applied to porous granular iron, the application of the above-mentioned porous granular iron in the treatment of inorganic and organic pollutants in liquids and gases, the preparation of the above-mentioned porous granular iron, the above-mentioned porous particles In the field of iron regeneration, it can solve the problems of low reactivity and low specific surface of iron filings of large iron particles, and achieve the effect of high processing activity, high water permeability and low density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Iron powder is mixed with polyvinyl alcohol, the agglomerated iron is treated at a temperature of 110° C., and sieved to obtain a porous granular iron product with a particle size in the range of 0.42-1.19 mm. Table 1 lists the properties of the porous iron granules and the commercial non-porous iron granules. The density of the porous granular product is four times smaller than that of the free granular iron, and its specific surface area is significantly higher than that of the free granular iron.

[0047] Table 1. Properties of Porous Pellet Iron and Commercial Non-porous Pellets

[0048] product

Specific surface area (m 2 / g)

Particle size (mm)

Density (g / mL)

porous granular iron

3.7

0.42-1.19

1.0-1.2

commercialnon-porousgranular iron

<0.5

0.282-0.50

4.3

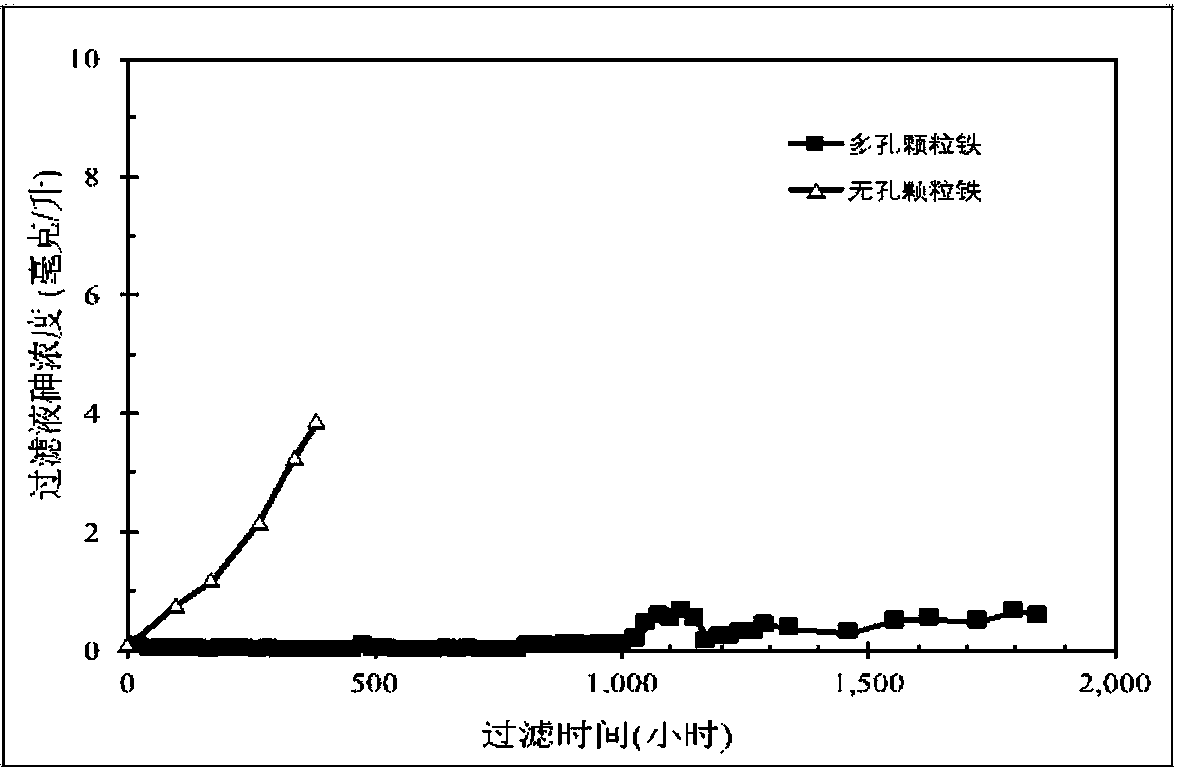

[0049] The porous granular iron product was loaded into a filter through which water containing 10 mg / L of As(V) arsenic acid was passed at a flow rate ...

Embodiment 2

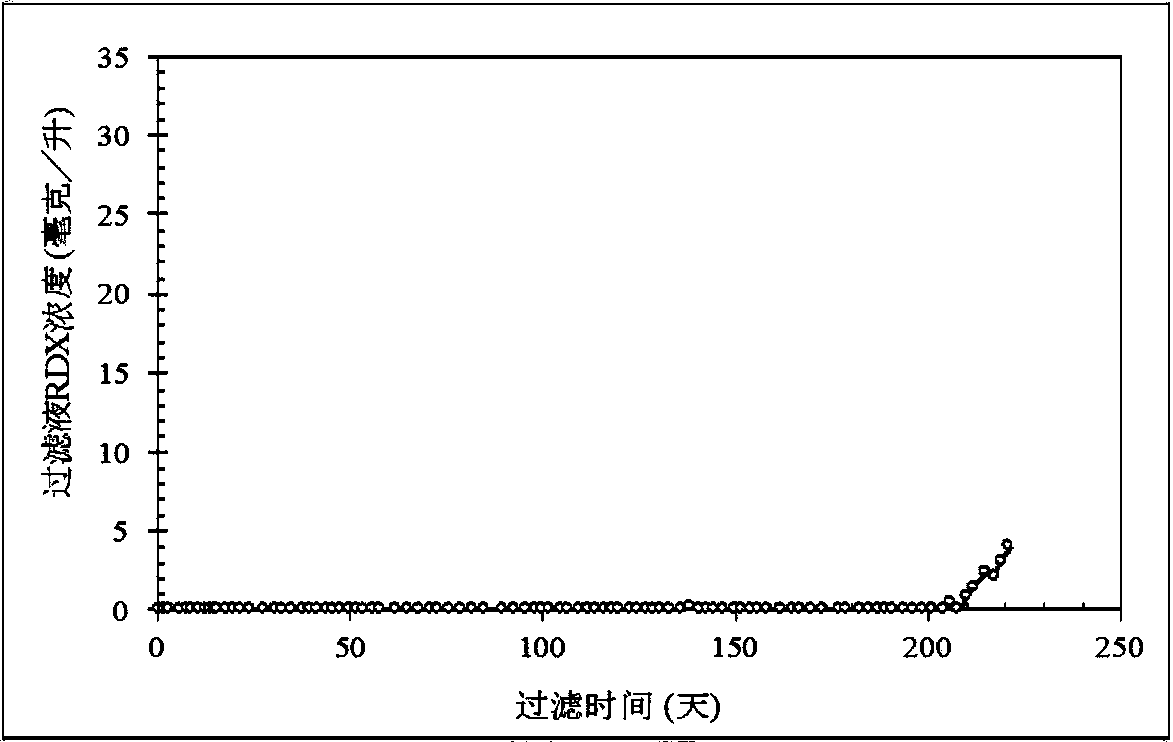

[0054]will contain 35 mg / L cyclotrimethylene trinitramine (C 3 h 6 N 6 o 6 , RDX) water is passed through a porous granular iron filter with an empty bed contact time of 2 hours, and the influent pH=5.

[0055] see figure 2 , showing that the effluent RDX concentration of the porous granular iron filter was less than 0.05 mg / L during the 210-day filtration period. The results show that the porous granular iron of the present invention can effectively treat nitroorganic compounds for a long time without agglomeration in the filter. However, it is known that iron particles will agglomerate in the filter after long-term filtration treatment, thereby reducing the reactivity and permeability of iron particles.

Embodiment 3

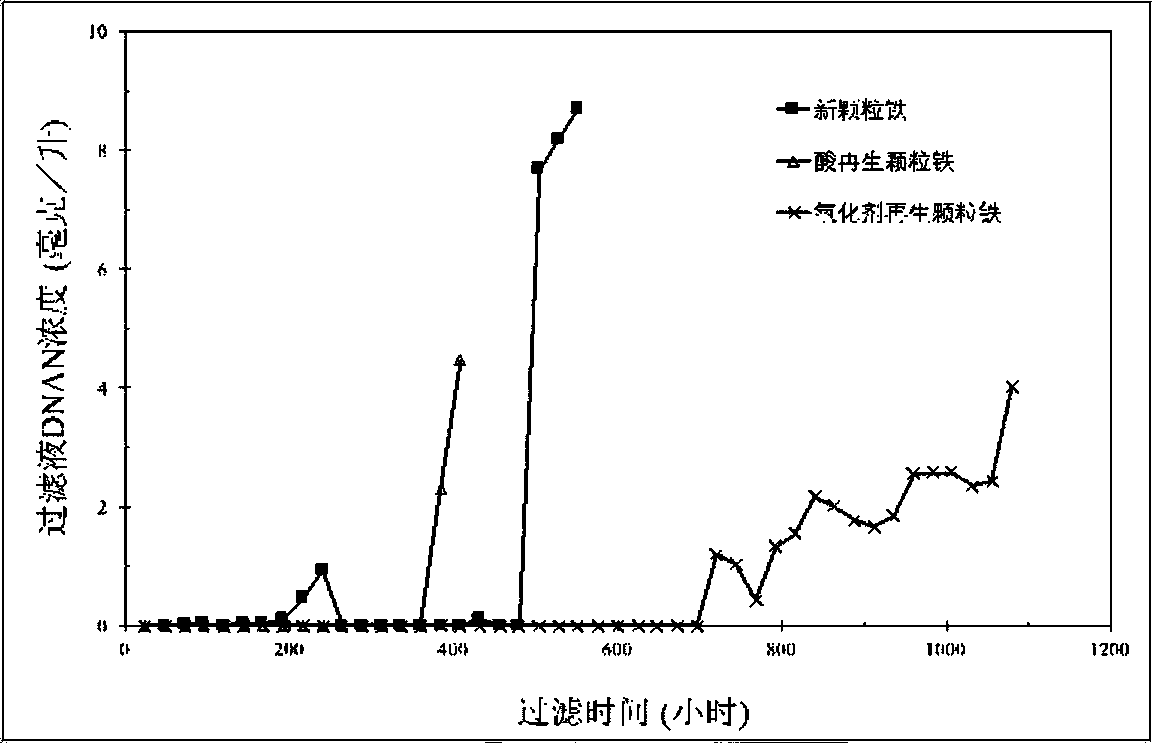

[0057] Water containing 10 mg / L 2,4-dinitroanisole (DNAN) was passed through a porous granular iron filter with an empty bed contact time of 1 h.

[0058] Please combine image 3 , the result of using porous granular iron and regenerated granular iron to filter water containing 2,4-dinitroanisole (DNAN), raw water DNAN concentration = 10 mg / L, raw water pH = 7.3, empty bed contact time = 1 Hour.

[0059] image 3 showed that during the first 500 hours of filtration, the neoporous granular iron reduced the DNAN concentration from 10 to less than 0.9 mg / L. The oxidizer-regenerated and acid-regenerated porous granular iron filters effectively filtered DNAN-containing water for 700 and 350 hours, respectively. The results show that the regenerated porous iron particles can effectively treat nitroorganic compounds. The oxidant and acid used for regeneration in this embodiment are known technologies.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com