Gas deep dehumidification film and preparation method thereof

A deep, gas technology, applied in the field of gas deep dehumidification membrane and its preparation, can solve the problems of low mechanical strength of drying tube, high price of drying tube, complex equipment and other problems, and achieve easy batch production, excellent corrosion resistance, no equipment required Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

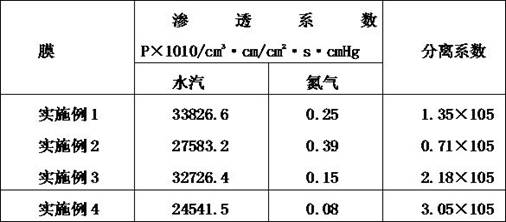

Examples

Embodiment 1

[0029] The gas deep dehumidification membrane includes two parts: a modified porous skeleton and a water-removing functional resin compound; the modified porous skeleton plays a supporting role as the main body of the dehumidifying membrane; the water-removing functional resin compound can be selectively and directionally removed Water molecules, the two promote each other to complete the deep removal of water molecules in the gas.

[0030] The modified porous skeleton and the water-removing functional resin compound are composited into an integral structure by filling or coating; the modified porous skeleton accounts for 5-90% by mass of the deep gas dehumidification membrane.

[0031] The modified porous skeleton is formed by modifying the porous skeleton by surface plasma or chemical grafting; the porous skeleton is polytetrafluoroethylene membrane, polyvinylidene fluoride membrane, polyacrylonitrile membrane, polyethylene membrane, Polypropylene membrane, porous ceramic me...

Embodiment 2

[0039] The gas deep dehumidification membrane includes two parts: a modified porous skeleton and a water-removing functional resin compound; the modified porous skeleton plays a supporting role as the main body of the dehumidifying membrane; the water-removing functional resin compound can be selectively and directionally removed Water molecules, the two promote each other to complete the deep removal of water molecules in the gas.

[0040] The modified porous skeleton and the water-removing functional resin compound are composited into an integral structure by filling or coating; the modified porous skeleton accounts for 5-90% by mass of the deep gas dehumidification membrane.

[0041] The modified porous skeleton is formed by modifying the porous skeleton by surface plasma or chemical grafting; the porous skeleton is polytetrafluoroethylene membrane, polyvinylidene fluoride membrane, polyacrylonitrile membrane, polyethylene membrane, Polypropylene membrane, porous ceramic me...

Embodiment 3

[0049] The gas deep dehumidification membrane includes two parts: a modified porous skeleton and a water-removing functional resin compound; the modified porous skeleton plays a supporting role as the main body of the dehumidifying membrane; the water-removing functional resin compound can be selectively and directionally removed Water molecules, the two promote each other to complete the deep removal of water molecules in the gas.

[0050] The modified porous skeleton and the water-removing functional resin compound are composited into an integral structure by filling or coating; the modified porous skeleton accounts for 5-90% by mass of the deep gas dehumidification membrane.

[0051] The modified porous skeleton is formed by modifying the porous skeleton by surface plasma or chemical grafting; the porous skeleton is polytetrafluoroethylene membrane, polyvinylidene fluoride membrane, polyacrylonitrile membrane, polyethylene membrane, Polypropylene membrane, porous ceramic me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com