Easily dispersed aluminum oxide for ceramic membrane of lithium battery and preparation method thereof

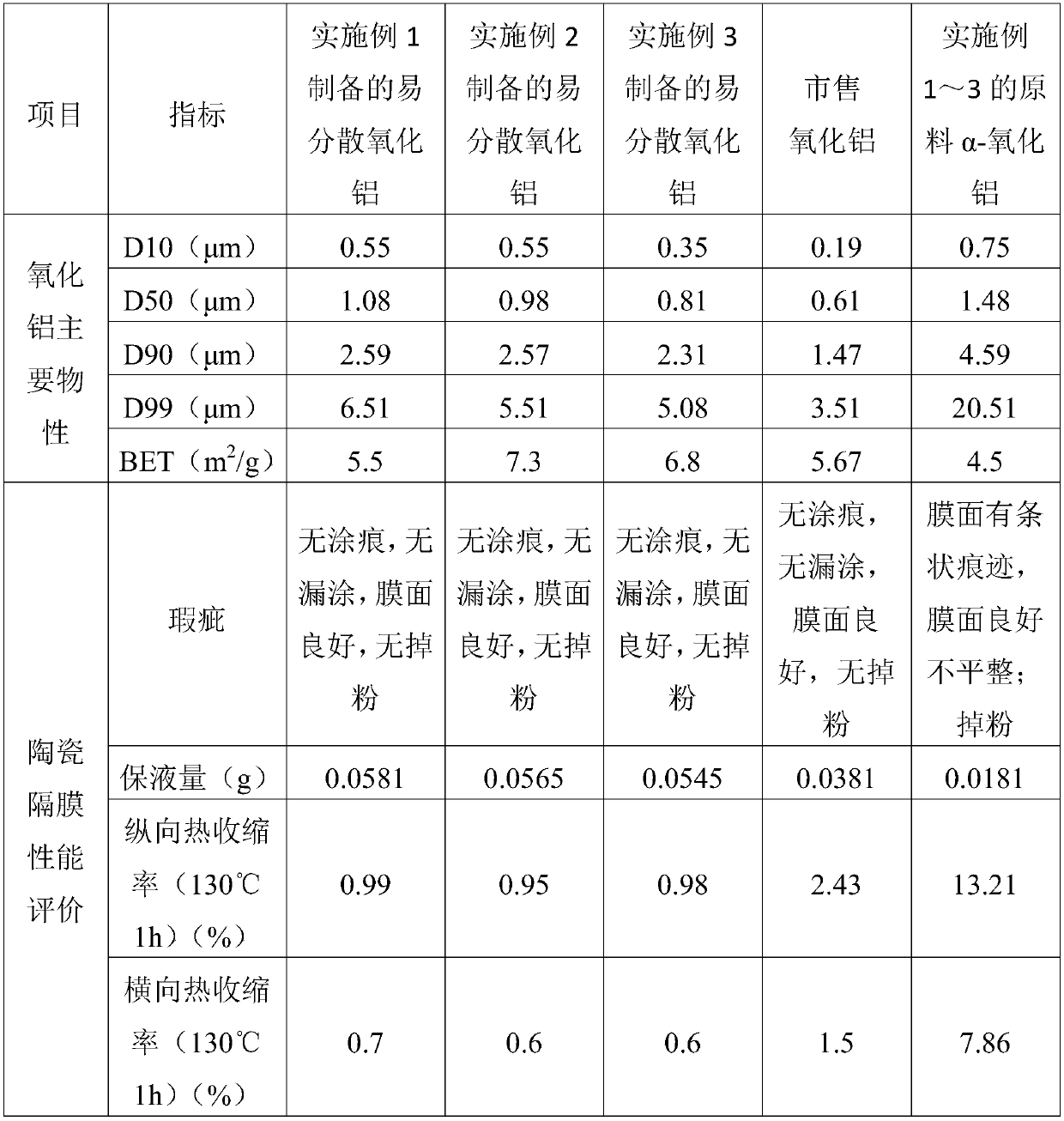

A ceramic diaphragm, alumina technology, applied in battery pack parts, circuits, electrical components, etc., to achieve the effects of low magnetic substances, narrow particle size distribution, and good dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment 1

[0042] S1. Beating and grinding: under stirring conditions, the content of 1000kg is 99.5%, and the specific surface area is 4.5m 2 / g of α-alumina was added to 1000kg of water for mixing and beating. The mixed slurry is purified by a magnetic separator made of magnetic materials that are excited and magnetized (the magnetic field strength of the pipeline filter iron remover is not less than 12000GS), and the content of magnetic substances in the slurry is calculated by mass, accounting for the total solid content in the slurry. 0.5ppm;

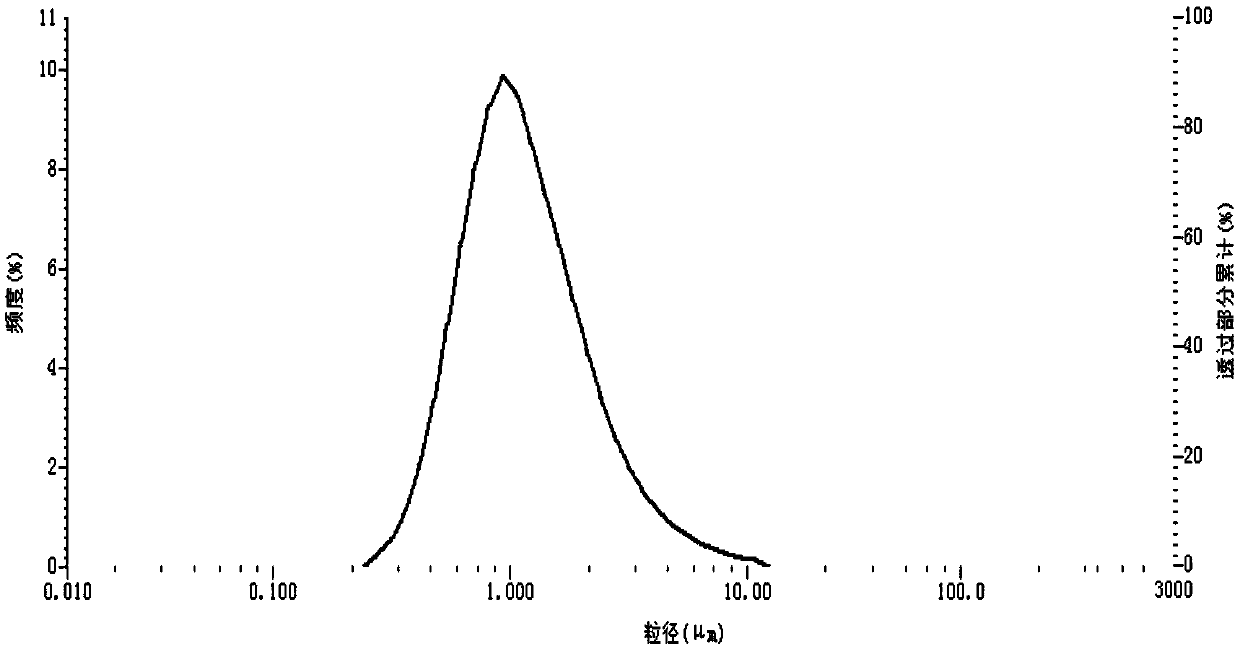

[0043] S2. Grinding and sieving: Grinding the slurry after beating and removing iron in step S1 to alumina particle size D through high-energy ball milling 50 The particle size is 1.1 μm, and D 10 0.55μm, D 90 2.69 μm, D 99 is 6.61 μm. After being screened by a vibrating sieving machine equipped with a 500-mesh screen, it is ready for use;

[0044] S3. Dehydration and drying: dehydrate the slurry ground and sieved in step S2 through pla...

Embodiment 2

[0052] S1. Beating and grinding: under stirring conditions, the content of 1000kg is 99.1%, and the specific surface area is 6.4m 2 / g of α-alumina was added to 2300kg of water for mixing and beating. The mixed slurry is purified by a magnetic separator made of magnetic materials that are excited and magnetized (the magnetic field strength of the pipeline filter iron remover is not less than 12000GS), and the content of magnetic substances in the slurry is calculated by mass, accounting for the total solid content in the slurry. 0.9ppm;

[0053] S2. Grinding and sieving: Grinding the slurry after beating and removing iron in step S1 to alumina particle size D through high-energy ball milling 50 The particle size is 1.0μm, and D 10 0.55μm, D 90 2.59 μm, D 99 is 5.7 μm. After being screened by a vibrating sieving machine equipped with a 500-mesh screen, it is ready for use;

[0054] S3. Dehydration and drying: the slurry ground and screened in step S2 is dehydrated by plat...

Embodiment 3

[0060] S1. Beating and grinding: under stirring conditions, the content of 1000kg is 99.8%, and the specific surface area is 5.7m 2 / g of α-alumina was added to 1500kg of water for mixing and beating. The mixed slurry is purified by a magnetic separator made of magnetic material with excitation and magnetization (the magnetic field strength of the pipeline filter iron remover is not less than 12000GS), and the content of the magnetic substance in the slurry is calculated by mass, accounting for the total solid content in the slurry. 0.1ppm;

[0061] S2. Grinding and sieving: Grinding the slurry after beating and removing iron in step S1 to alumina particle size D through high-energy ball milling 50 The particle size is 0.82μm, and D 10 0.35μm, D 90 2.32 μm, D 99 5.1 μm. After passing through a vibrating sieving machine equipped with a 550-mesh sieve, it is used for standby;

[0062] S3, dehydration and drying: the slurry ground and screened in step S2 is dehydrated by pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com