Method for jointly preparing electric vehicle grade lithium carbonate and lithium hydroxide monohydrate

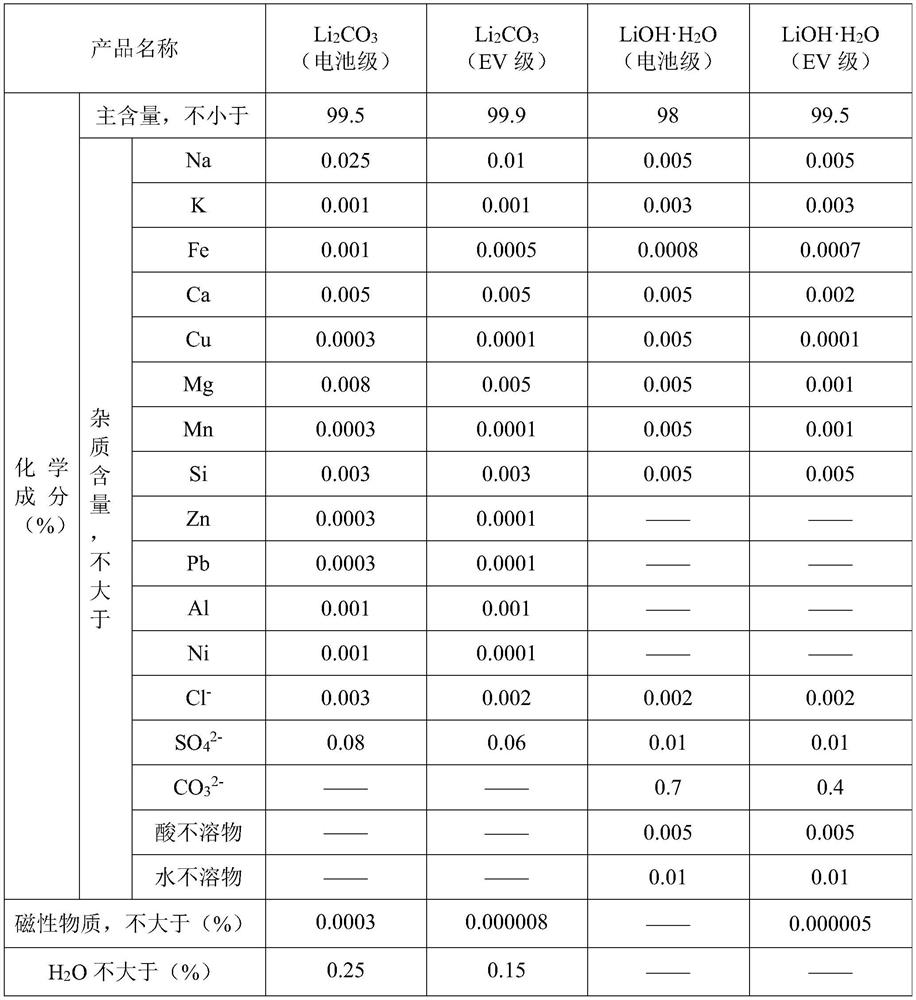

A monohydrate lithium hydroxide, electric vehicle technology, applied in the direction of lithium oxide;/hydroxide, lithium carbonate;/acid carbonate, etc., to achieve low magnetic substance, high product yield and product quality excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

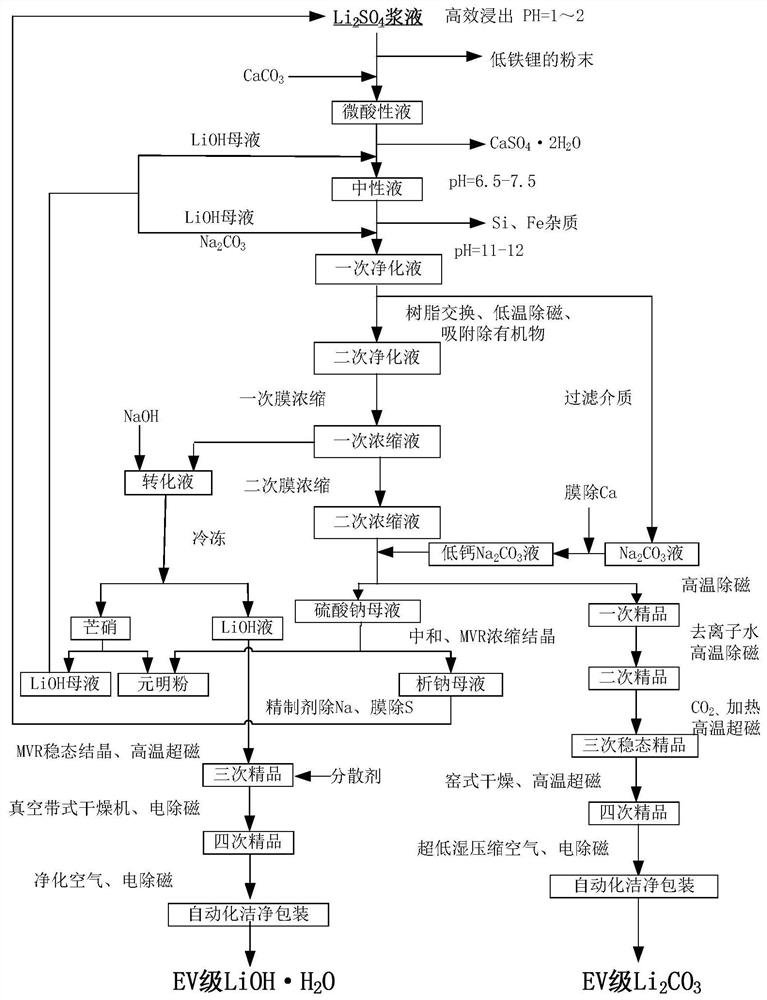

[0110] Such as figure 1 Shown, adopt following steps to produce and obtain EV grade lithium carbonate and EV grade lithium hydroxide monohydrate:

[0111] A. Slurry treatment: After filtering the lithium sulfate slurry, add 12kg / m3 to the filtrate 3calcium carbonate, solid-liquid separation to obtain calcium sulfate dihydrate solid and slightly acidic liquid, wherein, the lithium sulfate slurry is the leaching slurry obtained by leaching lithium ore after acidification and roasting, the pH value of the lithium sulfate slurry is 1, and the specific gravity is 1.2 , the concentration is Li 2 The O content was calculated as 30 g / L.

[0112] B. Twice neutralization and purification: adjust the pH of the slightly acidic solution in step A to 6.5, react for 30 minutes, and filter to obtain a neutral solution; then add a concentration of 300 ± 10g / L sodium carbonate solution 1.5 liters / Prepare a neutral solution, adjust the pH to 11, react for 30 minutes, and filter to obtain a p...

Embodiment 2

[0129] Such as figure 1 Shown, adopt following steps to produce and obtain EV grade lithium carbonate and EV grade lithium hydroxide monohydrate:

[0130] A. Slurry treatment: After filtering the lithium sulfate slurry, add 16kg / m3 to the filtrate 3 calcium carbonate, solid-liquid separation to obtain calcium sulfate dihydrate solid and slightly acidic liquid, wherein, the lithium sulfate slurry is the leaching slurry obtained by leaching lithium ore after acidification and roasting, the pH value of the lithium sulfate slurry is 2, and the specific gravity is 1.4 , the concentration is Li 2 The O content was calculated as 32 g / L.

[0131] B. Twice neutralization and purification: adjust the pH of the slightly acidic solution in step A to 7.5, react for 40 minutes, filter to obtain a neutral solution; then add a concentration of 300 ± 10g / L sodium carbonate solution 2 liters / Prepare a neutral solution, adjust the pH to 12, react for 40 minutes, and filter to obtain a primar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com