High-temperature self-crosslinking flame-retardant, smoke-suppressing, and anti-droplet copolyester based on benzamide structure and its preparation method and application

A self-crosslinking and anti-droplet technology, which is applied in the direction of additive processing, can solve the problems of not being able to be used as textile fiber raw materials, the large amount of smoke released by flame-retardant polyester, and the damage to the processing performance of polyester, so as to inhibit the organic small Molecular volatilization, excellent flame retardancy, and the effect of promoting char formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

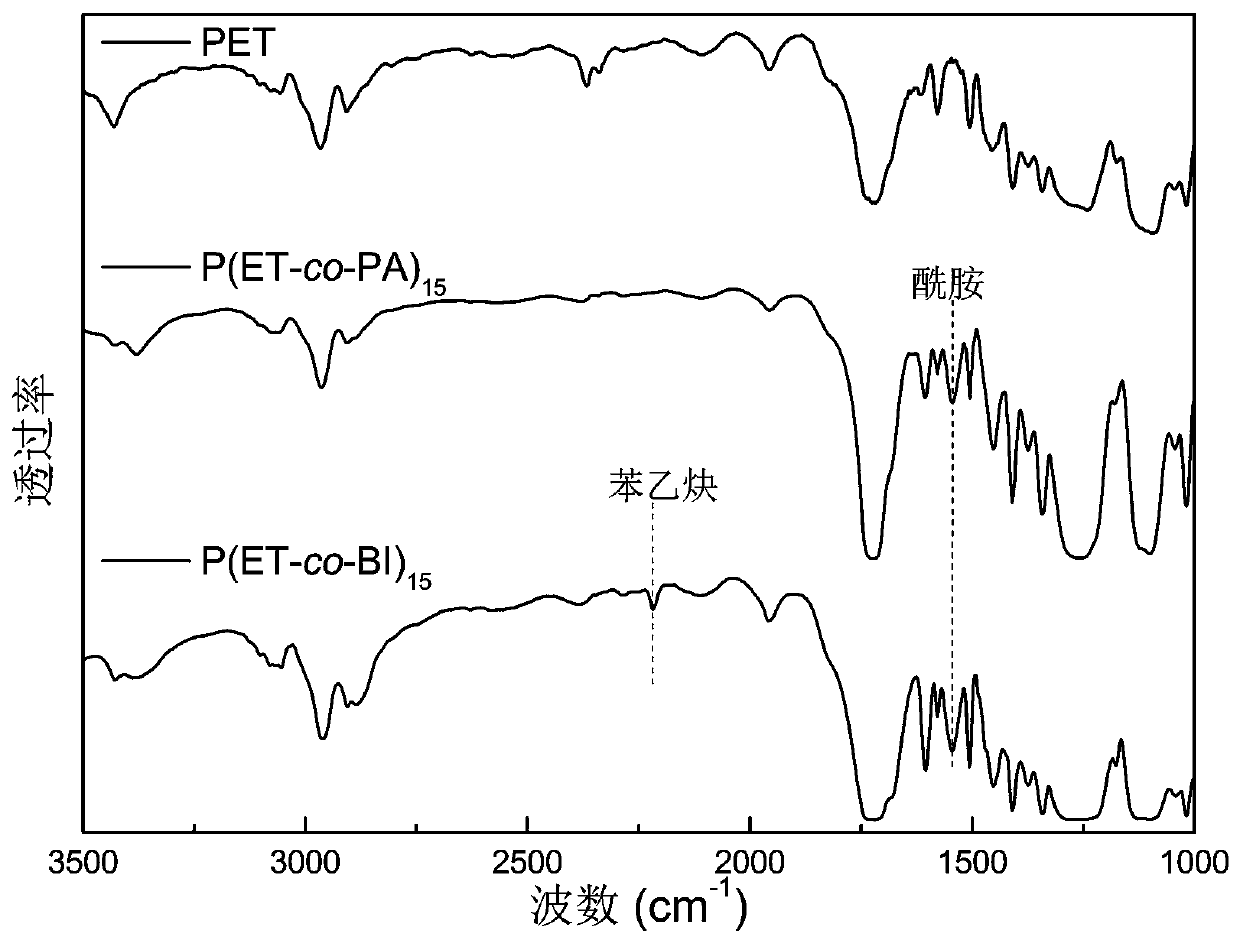

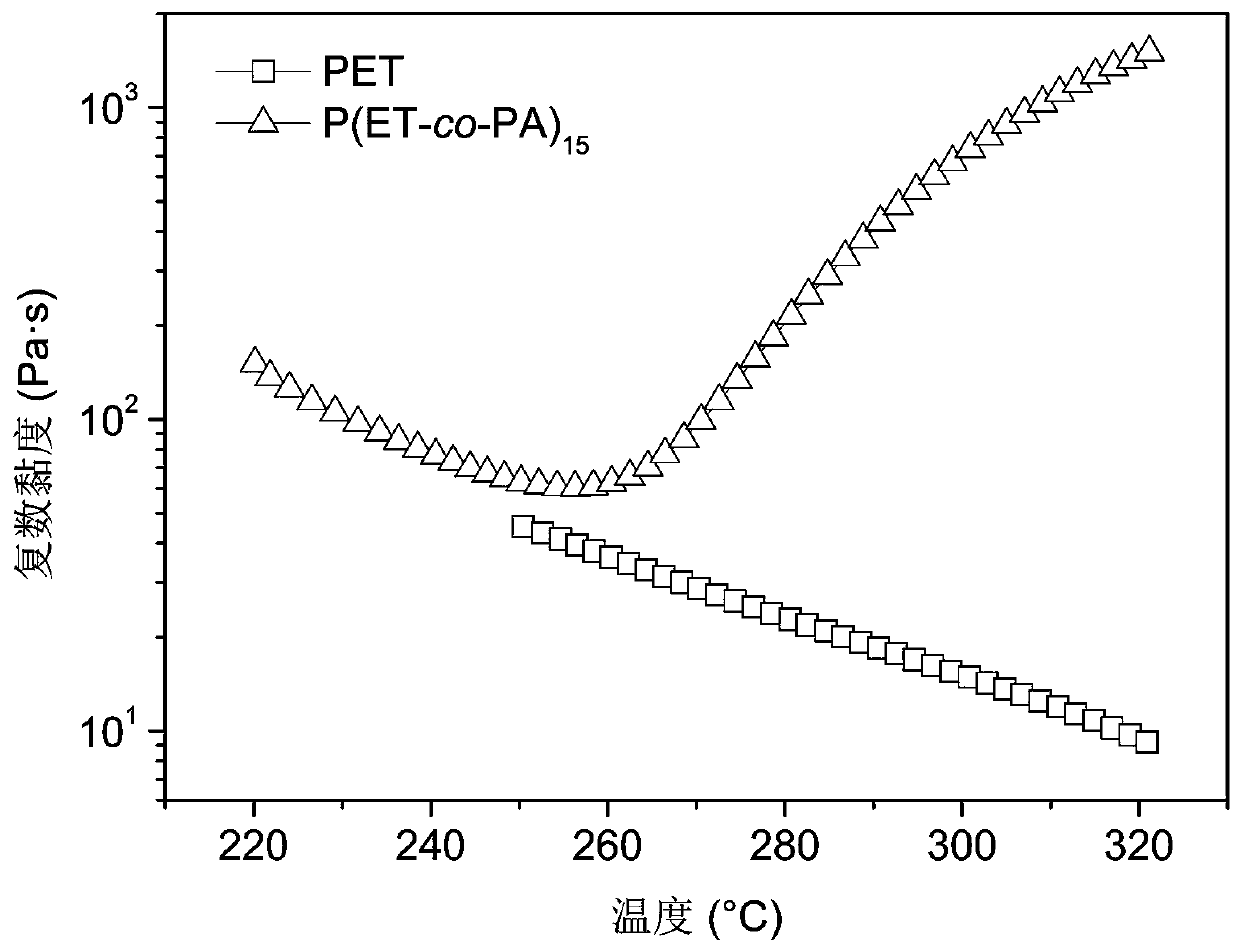

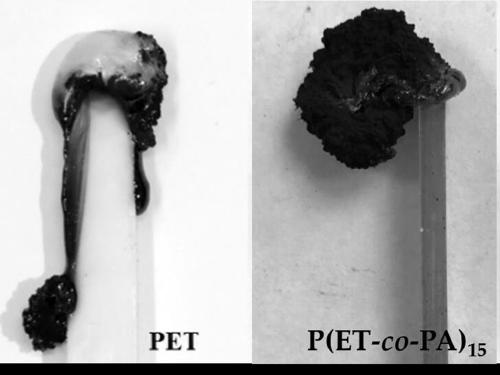

Method used

Image

Examples

Embodiment 1

[0054] Add 582g dimethyl terephthalate, 310g ethylene glycol, 46.9g dimethyl 5-benzamido-1,3-phthalate, 1.0g zinc acetate and 0.8g antimony trioxide to the reaction kettle During the process, fill the reactor with nitrogen to remove the air in the kettle; carry out the reaction at 180°C for 2 hours at normal pressure, raise the temperature to 200°C for 2 hours, and then raise the temperature to 220°C for 1 hour, and the transesterification reaction is completed; then conduct the polycondensation reaction at 220-240°C in a low vacuum 0.5~1.5h, then polycondensation reaction at 230~250°C for 1~3 hours under high vacuum (pressure<60Pa), discharge and water cooling.

[0055] The intrinsic viscosity [η] of the high-temperature self-crosslinking flame-retardant, smoke-suppressing and anti-melting droplet copolyester copolyester is 0.75dL / g; the oxygen index is 27.3%, the vertical combustion level is V-2, and the cone calorimetry test The peak heat release rate p-HRR is 664kW / m 2 , ...

Embodiment 2

[0057] Add 582g dimethyl terephthalate, 310g ethylene glycol, 93.9g dimethyl 5-benzamido-1,3-phthalate, 1.0g zinc acetate and 0.8g antimony trioxide to the reaction kettle Among them, after carrying out transesterification reaction and polycondensation according to the step and the condition that embodiment 1 provides, discharging.

[0058] The intrinsic viscosity [η] of the high-temperature self-crosslinking flame-retardant, smoke-suppressing and anti-droplet copolyester copolyester is 0.70dL / g; the oxygen index is 28.7%, the vertical combustion level is V-2, and the cone calorimetry test The peak heat release rate p-HRR is 573kW / m 2 , the total smoke emission is 1201m 2 / m 2 .

Embodiment 3

[0060] Add 582g dimethyl terephthalate, 310g ethylene glycol, 140.9g dimethyl 5-benzamido-1,3-phthalate, 1.0g zinc acetate and 0.8g antimony trioxide to the reaction kettle Among them, after carrying out transesterification reaction and polycondensation according to the step and the condition that embodiment 1 provides, discharging.

[0061] The intrinsic viscosity [η] of the high-temperature self-crosslinking flame-retardant, smoke-suppressing and anti-melting droplet copolyester copolyester is 0.64dL / g; the oxygen index is 29.8%, the vertical combustion level is V-1, and the cone calorimetry test The peak heat release rate p-HRR is 398kW / m 2 , the total smoke emission is 994m 2 / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| peak heat release rate | aaaaa | aaaaa |

| release amount | aaaaa | aaaaa |

| peak heat release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com