Flame-retardant anti-dripping copolymer nylon as well as preparation method and application thereof

A technology of copolymerized nylon and anti-melting drop, applied in the field of copolymerized nylon and its preparation and application, can solve the problems of inability to solve the problem of nylon melting, deteriorate the spinnability of materials, and burn the flame-retardant nylon, and achieve excellent flame retardant and anti-corrosion properties. Melting drop, inhibition of organic small molecule volatilization, high flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 146g (1mol) of adipic acid and 116g (1mol) of hexamethylenediamine were dissolved in ethanol, reacted at 90°C to form a salt and precipitated, and were filtered and dried to form a 50wt% aqueous solution; 14.2g (0.05mol) of 5 -(3-Hydroxystyryl)isophthalic acid and 5.8g (0.05mol) of hexamethylenediamine were dissolved in ethanol, reacted at 90°C to form a salt, and then precipitated, filtered and dried to form a 50wt% aqueous solution. Add the two aqueous solutions into the reactor, raise the temperature to 230°C, pressurize to 2.2MPa, and carry out the prepolymerization reaction under these conditions for 1.5h. Subsequently, the water vapor in the system was gradually discharged, and when the pressure in the system dropped to normal pressure, the vacuum was started to 4000 Pa and the temperature of the system was gradually raised, and the polycondensation reaction was carried out at 260° C. for 1 hour to obtain the product.

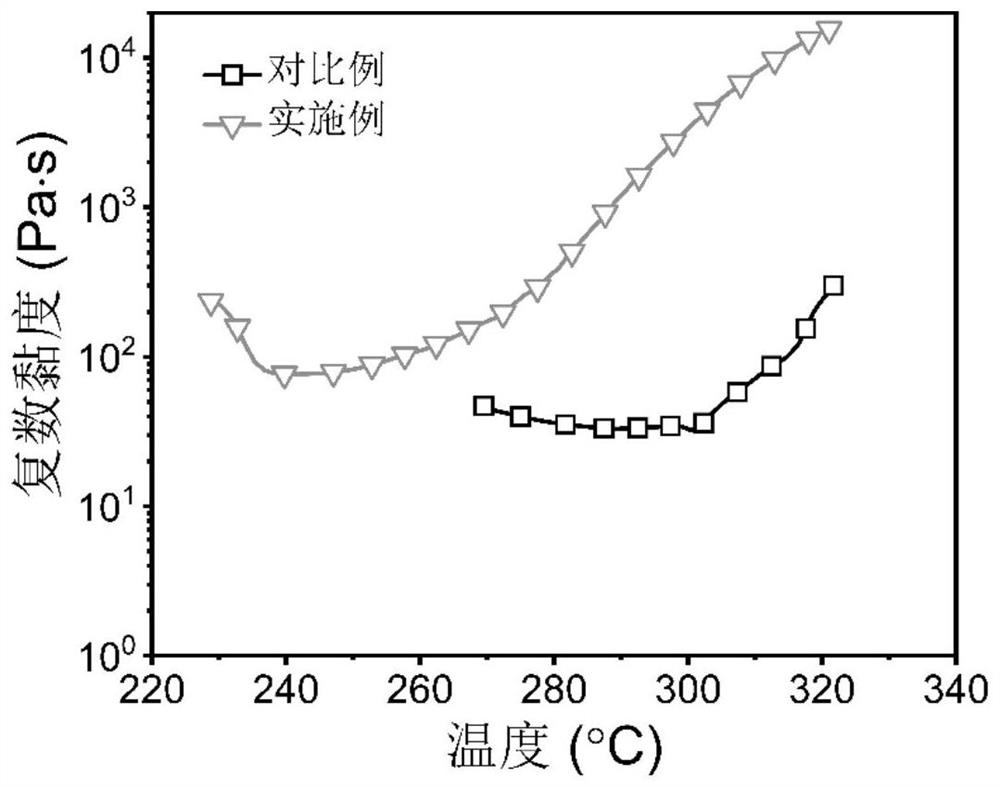

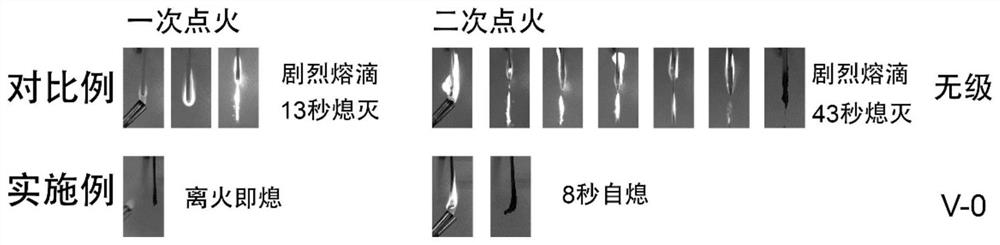

[0056] The intrinsic viscosity [η] of the co...

Embodiment 2

[0058] 105.6g (1.2mol) butanediamine, 96g (2.4mol) sodium hydroxide and 5g tetrabutylammonium chloride were dissolved in 1L of secondary water to configure solution A; 183g (1mol) adipoyl chloride and 60.6g ( 0.2mol) of 5-phenylethynyl isophthaloyl chloride was dissolved in 2L of dichloromethane to prepare solution B. Weigh solution A and solution B so that the number of moles of all diamines: the number of moles of all dibasic acid chlorides = 1:1; under rapid stirring at 2000rpm, quickly pour solution B into solution A, and continue stirring for 30 minutes to complete A large number of fibrous solids were precipitated during polymerization, and the product was obtained after suction filtration, washing and drying.

[0059] The intrinsic viscosity [η] of the copolymerized nylon is 1.21dL / g; the oxygen index is 34.2%, the vertical combustion grade V-0 does not melt, the tensile strength is 62MPa, and the tensile modulus is 1884MPa.

Embodiment 3

[0061] 146g (1mol) of adipic acid and 102g (1mol) of pentamethylenediamine were dissolved in ethanol, reacted at 90°C to form a salt and precipitated out, and were filtered and dried to form a 70wt% aqueous solution; 21.1g (0.1mol) of 4 '-Aminobenzylidene-4-aminoaniline and 16.6g (0.1mol) of adipic acid were dissolved in ethanol, reacted at 90°C to form a salt, and then precipitated. After filtering and drying, it was configured into a 70wt% aqueous solution. First add the two aqueous solutions into the reaction kettle, then add adipic acid, and make the moles of all diamines: the moles of all dibasic acids = 0.8:1, raise the temperature to 220°C, pressurize to 1.6MPa, Under these conditions, the prepolymerization reaction was carried out for 2h. Subsequently, the water vapor in the system was gradually discharged, and when the pressure in the system dropped to normal pressure, vacuuming was started to 5000 Pa and the temperature of the system was gradually raised, and the pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com