Waterproof and moisture permeable polyethylene film and preparation method thereof

A waterproof and moisture-permeable membrane and polyethylene technology, applied in the field of waterproof and moisture-permeable membrane materials, can solve the problems of pore size stability and poor waterproof performance, and achieve excellent hydrostatic pressure resistance, low production cost, and good moisture permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

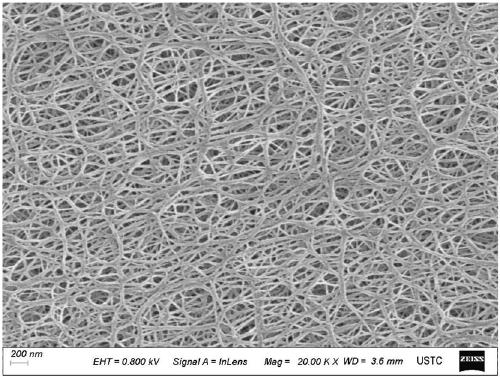

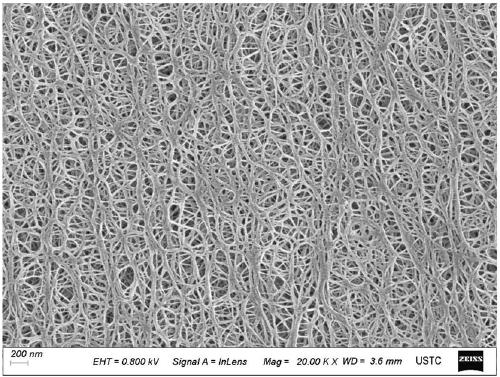

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing a polyethylene waterproof and moisture-permeable membrane, comprising the following steps:

[0024] S1. The polyethylene raw material is mixed with white oil, melted and extruded, and cast and cooled to obtain a cast oil film; the polyethylene raw material has a weight average molecular weight of 600,000 to 800,000. The mass ratio of oil is 1: (1.5~2.5);

[0025] S2. After heating the cast oil film to 90-110°C, perform asynchronous biaxial stretching, and then undergo heat setting and cooling to obtain a biaxially stretched oil film; the longitudinal ratio of the biaxial stretching is 3-5, and the transverse Rabbi is 5~8;

[0026] S3. Ultrasonic extraction is performed on the biaxially stretched oil film. The extraction agent used in the ultrasonic extraction is n-hexane or methylene chloride, and then the extracted film is dried to obtain a polyethylene waterproof and moisture-permeable film.

[0027] The polyethylene wat...

Embodiment 1

[0041] (1) Take 1.5kg polyethylene raw material (weight average molecular weight is 600,000, density is 0.96g / cm 3 ), mixed evenly with solvent white oil 68# in a mass ratio of 1:2, added 0.5% BHT type antioxidant, and then put the obtained polyethylene solution into a preheating kettle with a temperature of 100°C for preheating, preheating The time is 1h;

[0042] (2) Melt and extrude the preheated polyethylene solution through a twin-screw extruder at 235 ° C and a screw speed of 60 rpm, and then rapidly cool it through a casting roll at 20 ° C and a roll speed of 5 rpm to obtain a stream extended oil film;

[0043] (3) Fix the casting oil film obtained above on the fixture in the biaxial stretching device, then push the fixture to the preheating furnace for preheating, the preheating temperature is 68°C, then transport the fixture to the heating furnace, and the heating time 2min, the temperature is 100°C;

[0044] (4) Carry out the asynchronous two-way stretching of ver...

Embodiment 2

[0051] (1) Take 1.5kg polyethylene raw material (weight average molecular weight is 800,000, density is 0.96g / cm 3 ), mixed evenly with solvent white oil 70# at a ratio of 1:2, added 0.5% BHT type antioxidant, and then put the obtained polyethylene solution into a preheating kettle with a temperature of 100°C for preheating, and the preheating time for 1h;

[0052] (2) Melt and extrude the preheated polyethylene solution through a twin-screw extruder at 235 ° C and a screw speed of 60 rpm, and then rapidly cool it through a casting roll at 20 ° C and a roll speed of 5 rpm to obtain a stream extended oil film;

[0053] (3) Fix the casting oil film obtained above on the fixture in the biaxial stretching device, then push the fixture to the preheating furnace for preheating, the preheating temperature is 68°C, then transport the fixture to the heating furnace, and the heating time 2min, the temperature is 100°C;

[0054] (4) Carry out the asynchronous two-way stretching of ver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Water vapor transmission rate | aaaaa | aaaaa |

| Pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com