A method for flattening gan deep trenches for leds

A manufacturing method and planarization technology, which can be applied to semiconductor devices, electrical components, circuits, etc., can solve the problem of inability to achieve planarization of GaN deep grooves, and achieve the effects of high yield, easy manufacturing process, and consistent thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

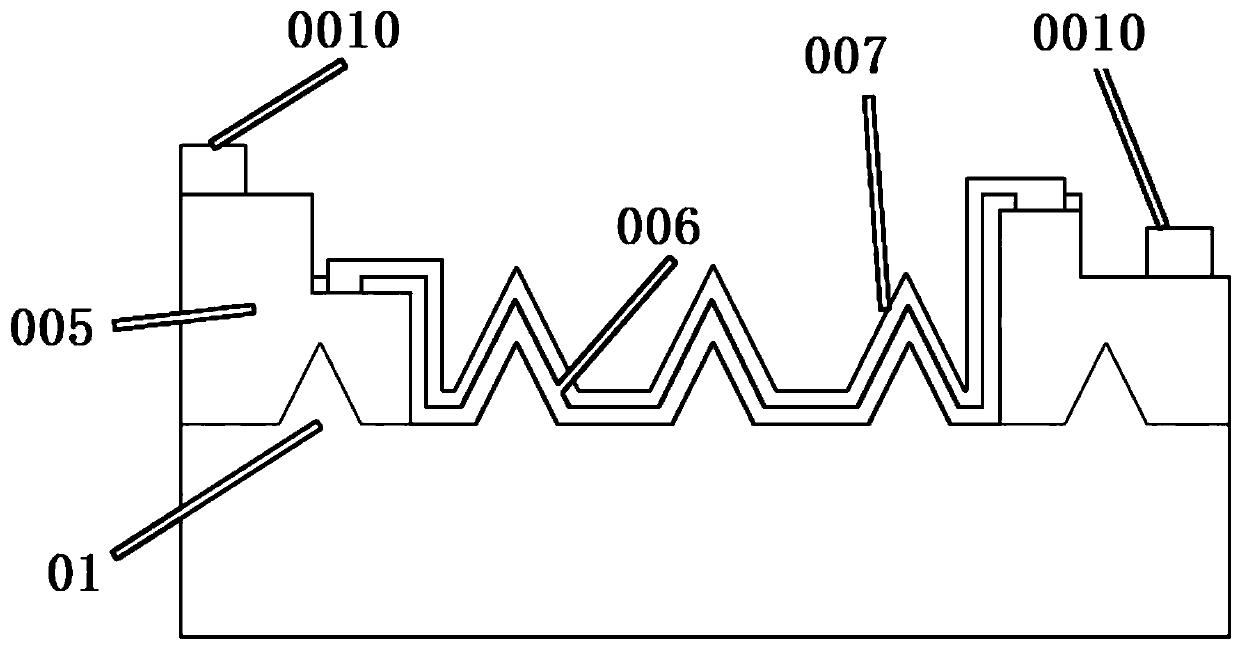

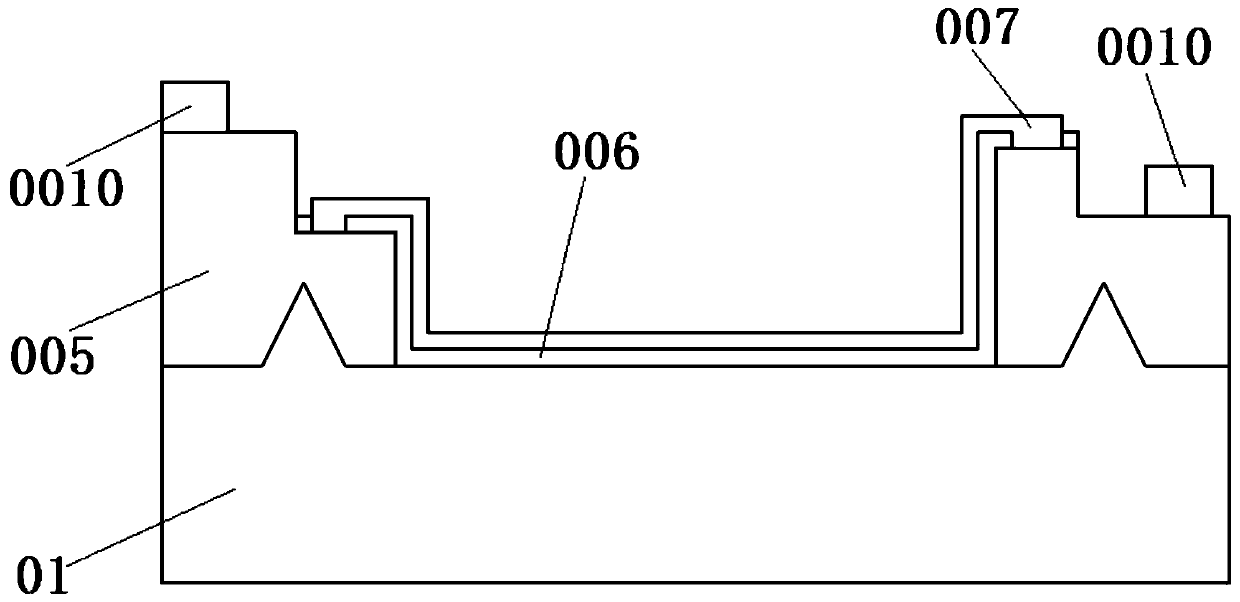

[0038] Embodiment 1: A method for making GaN deep trench planarization for LEDs, comprising the following steps:

[0039] Step 1. Select the sapphire flat substrate 001, and deposit a layer of insulating layer 002 on the sapphire flat substrate 001;

[0040] In this embodiment, the insulating layer 002 includes SiO 2 ;

[0041] Step 2. Form a patterned first mask window 003 on the insulating layer 002 through a photolithography process;

[0042] Step 3. Etching the insulating layer 002 under the cover of the first mask window 003 through an etching process to obtain a tapered insulating layer 004, and removing the first mask window 003;

[0043] The etching process adopts ICP dry etching. By adjusting the radio frequency power and the power of the upper and lower electrodes of the etching equipment, the lateral etching of the insulating layer 002 is increased, so that the insulating layer 002 is etched into a tapered insulating layer 004; due to the flat sapphire substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com