Crisp pickled cowpea chip and processing method thereof

A processing method, the technology of sour cowpea, is applied in the direction of food ultrasonic treatment, the function of food ingredients, food ingredients containing natural extracts, etc., and can solve the problems that cannot meet consumers' requirements for vegetable nutrition, quality, hygiene and convenience, leisure Food research is too little, processing quality is not high, etc., to achieve the effect of improving food value, sensory quality and food value, and improving the degree of fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

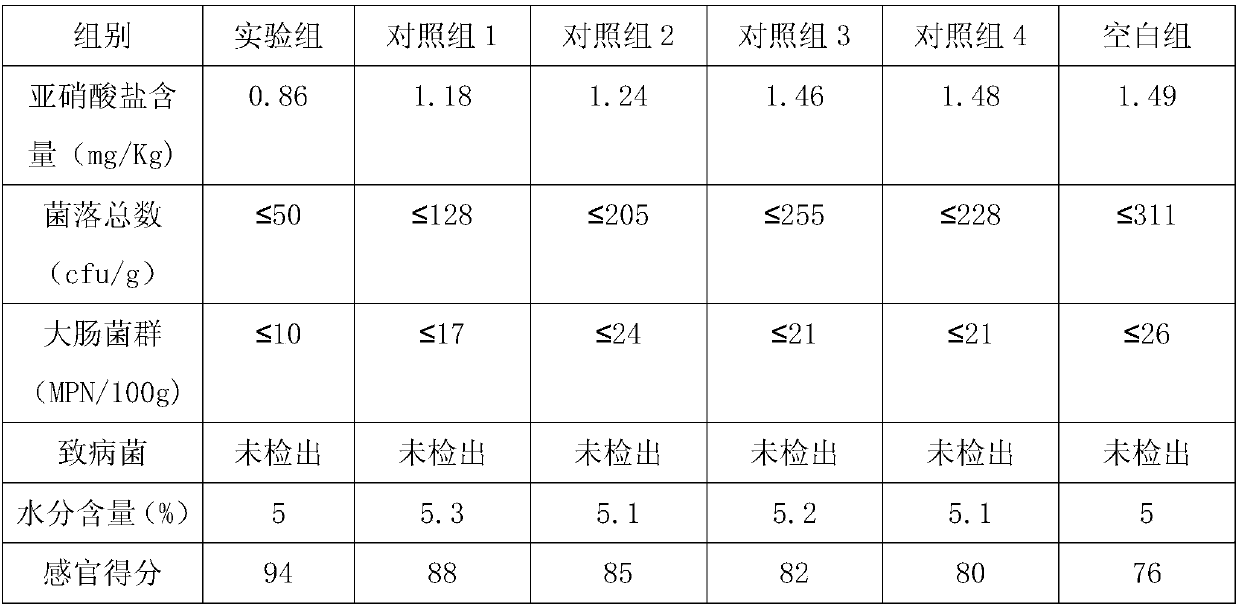

Examples

Embodiment 1

[0024] A processing method for sour cowpea chips, comprising the following steps:

[0025] (1) Weighing raw materials, said raw materials include the following components by weight: 20 parts of sour cowpea, 3 parts of β-cyclodextrin, 1 part of sodium bicarbonate, 1 part of cysteine and 1 part of modified starch;

[0026] (2) Preparation of quality improver: after mixing and stirring the weighed β-cyclodextrin and water according to the mass ratio of 1:5, add the weighed modified starch and mix evenly to obtain a mixed solution. Ultrasonic treatment at 10KHz for 5 minutes, then heat preservation treatment at 65°C for 5 minutes, then add the weighed sodium bicarbonate and cysteine, and finally magnetically stir at 55°C for 15 minutes to obtain the quality improver for future use;

[0027] (3) Preparation of the dipping solution: mix and stir the weighed Luo Han Guo extract, perilla stalk extract, pomelo peel extract and water until uniform, to obtain the dipping solution with ...

Embodiment 2

[0031] A processing method for sour cowpea chips, comprising the following steps:

[0032] (1) Weighing raw materials, said raw materials include the following components by weight: 28 parts of sour cowpea, 4 parts of β-cyclodextrin, 2 parts of sodium bicarbonate, 1.5 parts of cysteine and 1.5 parts of modified starch;

[0033] (2) Preparation of quality improver: after mixing and stirring the weighed β-cyclodextrin and water according to the mass ratio of 1:5, add the weighed modified starch and mix evenly to obtain a mixed solution. Ultrasonic treatment at 13KHz for 8 minutes, then heat preservation treatment at 68°C for 7 minutes, then add the weighed sodium bicarbonate and cysteine, and finally stir magnetically at 60°C for 18 minutes to obtain the quality improver for future use;

[0034] (3) Preparation of the dipping solution: mix and stir the weighed Luo Han Guo extract, perilla stalk extract, pomelo peel extract and water until uniform, to obtain the dipping solutio...

Embodiment 3

[0038] A processing method for sour cowpea chips, comprising the following steps:

[0039] (1) Weighing raw materials, said raw materials include the following components by weight: 30 parts of sour cowpea, 5 parts of β-cyclodextrin, 3 parts of sodium bicarbonate, 3 parts of cysteine and 2 parts of modified starch;

[0040] (2) Preparation of quality improver: after mixing and stirring the weighed β-cyclodextrin and water according to the mass ratio of 1:5, add the weighed modified starch and mix evenly to obtain a mixed solution. Ultrasonic treatment at 15KHz for 10 minutes, then heat preservation treatment at 70°C for 8 minutes, then add the weighed sodium bicarbonate and cysteine, and finally magnetically stir at 65°C for 20 minutes to obtain the quality improver for future use;

[0041] (3) Preparation of dipping solution: mix and stir the weighed Luo Han Guo extract, perilla stalk extract, pomelo peel extract and water until uniform, to obtain the dipping solution with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com