Nail lengthening adhesive and preparation method and curing demoulding application thereof

A technology for extending glue and nails, applied in the field of manicure, can solve the problems of not being able to meet the needs of manicure, discomfort, and complicated operation, and achieve the effects of improving hardness, reducing heat release, and simplifying operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

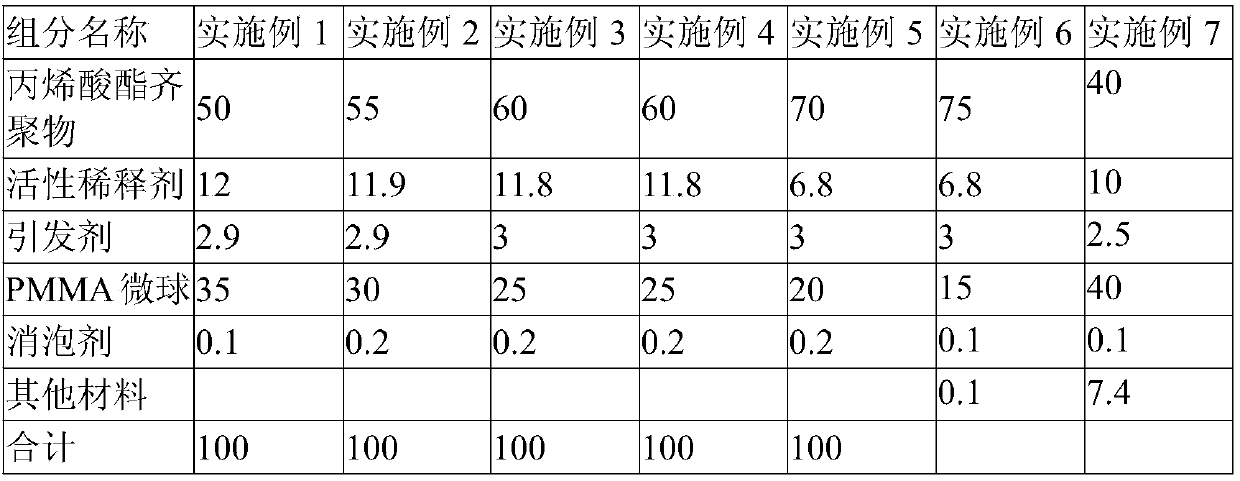

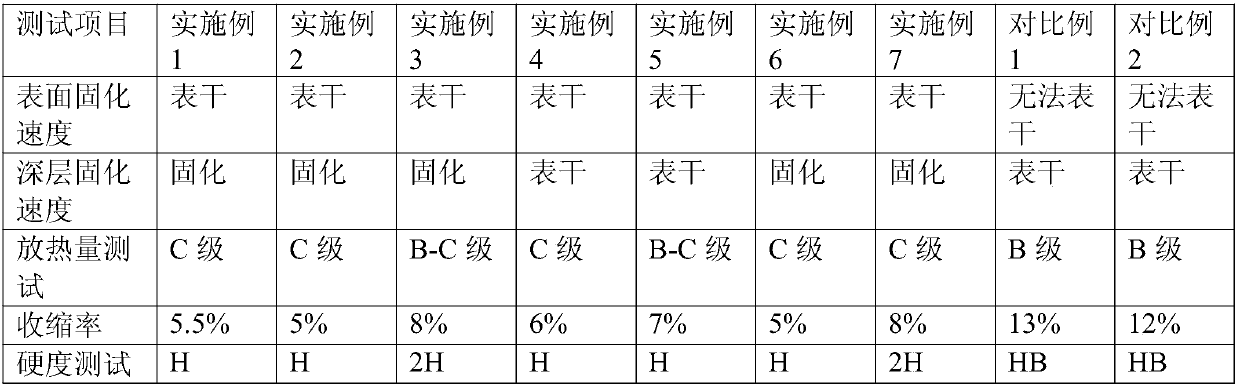

Examples

preparation example Construction

[0063] The preparation method of nail extension glue of the present invention includes the following steps:

[0064] (1) Add acrylate oligomer, reactive diluent, photoinitiator, and defoamer into a stirring vessel in a fixed proportion, and stir at 500-1000 revolutions / min for 30-60 minutes. The test temperature during stirring is not higher than 70 degrees Celsius.

[0065] (2) Add a certain proportion of acrylic powder to the mixture prepared in the first step, stir for 30-60 minutes at a speed of 500-1000 revolutions / min, while vacuuming to remove air bubbles, the test temperature is not higher than when stirring and deaeration 70 degrees Celsius.

[0066] The method of using the nail extension glue of the present invention includes the following steps:

[0067] S1) Take an appropriate amount of nail extension gel and put it in the release nail piece, dip a small amount of alcohol with a brush, and press the extension gel to cover the inner wall of the release nail to form the tar...

Embodiment 1

[0077] The acrylate oligomer is a trifunctional polyurethane acrylate, its number average molecular weight is 2000D, the reactive diluent is isobornyl acrylate, hydroxyethyl methacrylate, the mixing ratio is 1:2, and the initiator is diphenyl -(2,4,6-Trimethylbenzoyl)phosphorus oxychloride, 1-hydroxycyclohexyl phenyl ketone mixture, the mixing ratio is 1:1, PMMA microspheres have an average particle size of 20um, and the defoamer is BYK -065.

[0078] The preparation method of Example 1 is

[0079] 1. Add acrylate oligomer, reactive diluent, photoinitiator, and defoamer into a stirring vessel in a fixed proportion, and stir at 1000 rpm for 40 minutes. The test temperature during stirring is not higher than 70 degrees Celsius.

[0080] 2. Add acrylic powder to the mixture prepared in the first step in proportion, stir at 800 rpm for 30 minutes, while vacuuming to remove air bubbles, the test temperature is not higher than 70 degrees Celsius during stirring and deaeration, and cooling...

Embodiment 2

[0082] The acrylate oligomer is a four-functional polyurethane acrylate with a number average molecular weight of 2500D. The reactive diluent is trimethylolpropane triacrylate and hydroxyethyl methacrylate. The mixing ratio is 1:1. The initiator It is a mixture of 2-methyl-1-[4-(methylthio)phenyl]-2-(4-morpholinyl)-1-propanone and 1-hydroxycyclohexylphenyl ketone, the mixing ratio is 1 :3, PMMA microspheres have an average particle size of 30um, and the defoamer is Airex 920.

[0083] The preparation method of Example 2 is similar to that of Example 1, and the usage method is also similar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com