Simulation processing system for volatile organic compounds

An organic compound and simulation treatment technology, applied in the field of volatile organic compound simulation treatment system, can solve problems such as low affinity and strong hydrophobicity, and achieve the effects of simple and feasible operation, reduction of disassembly and installation, and reduction of debugging costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

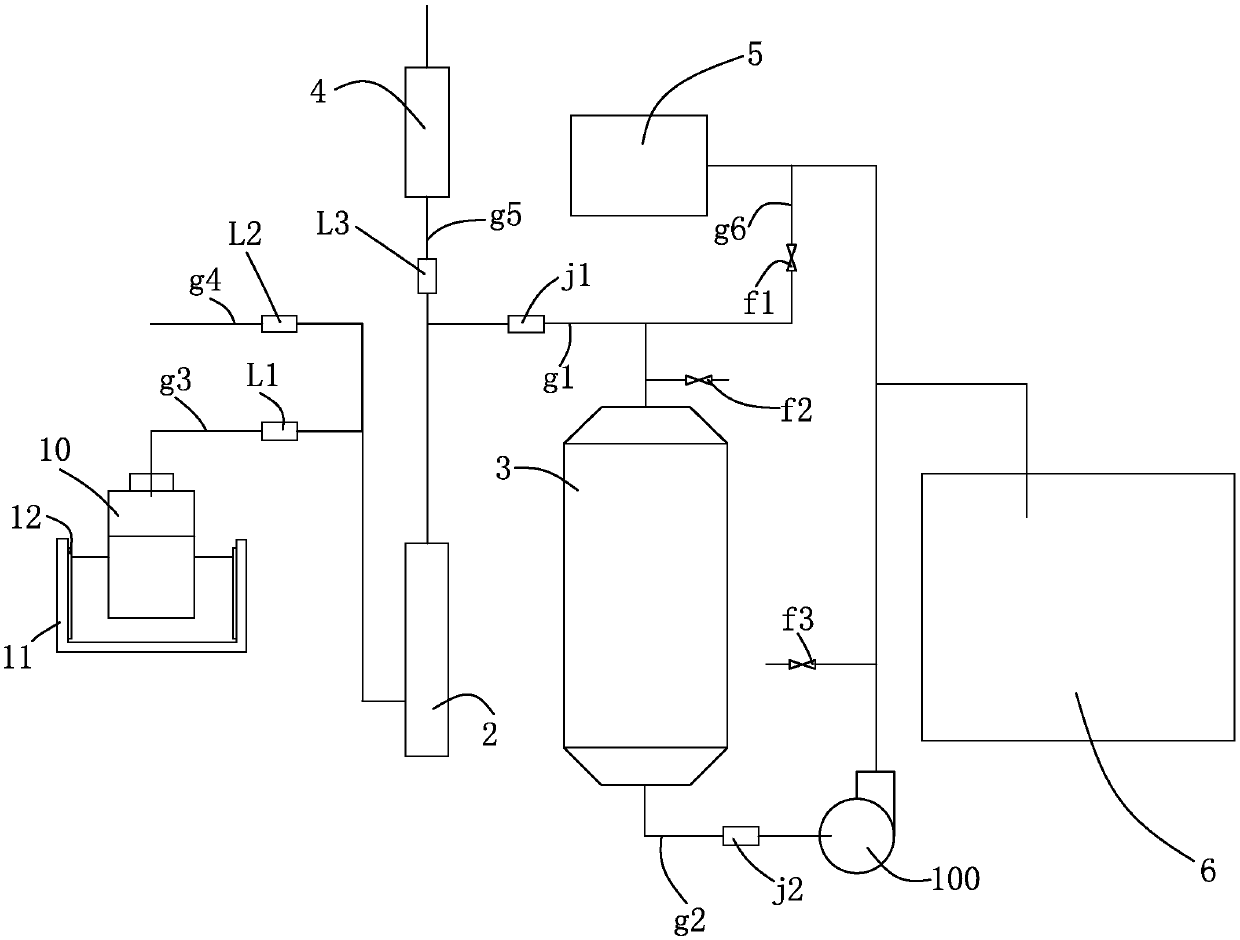

[0021] like figure 1 As shown, a simulated treatment system for volatile organic compounds, the treatment system is used to evaluate the adsorption and regeneration performance of the adsorption material under the simulated actual engineering conditions, the treatment system includes a gaseous VOCs generator, a carrier for providing carrier gas The gas feed pipe g4 is connected with the gaseous VOCs generating device and the carrier gas feed pipe g4, and the mixing device 2 is used to mix the carrier gas and the gaseous VOCs (the carrier gas and the gaseous VOCs are fully mixed in the mixing device 2 to form a simulated For industrial organic waste gas, the mixing device 2 is a Venturi tube or SV type mixer or SH type mixer or SK type mixer), an adsorption tower 3 for adsorbing and removing VOCs in the mixed gas, and a circulating fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com