Method for preparing camellia-flower-shaped nickel-based catalyst used for treating alkaline dyeing and finishing wastewater

A nickel-based catalyst, dyeing and finishing wastewater technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems that have not been seen yet, and achieve low impact , short time-consuming, low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

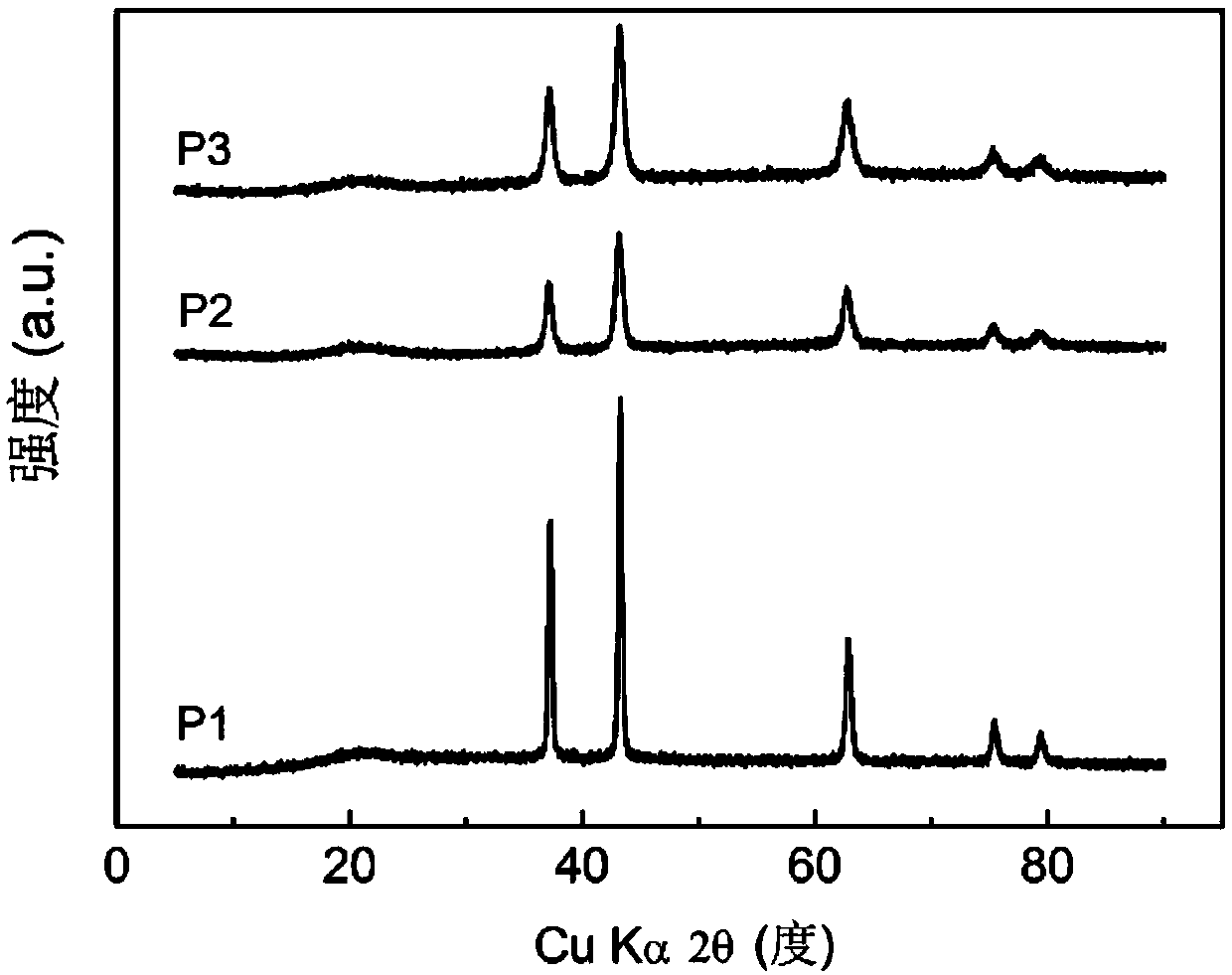

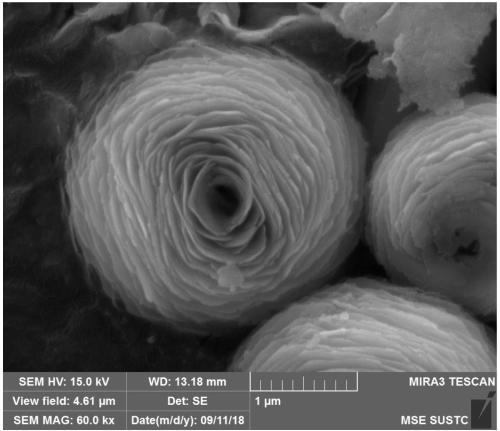

Embodiment 1

[0023] A method for preparing a camellia-shaped nickel-based catalyst for treating alkaline dyeing and finishing wastewater, comprising the steps of:

[0024] S1, camellia-like β-Ni(OH) 2 Precursor preparation:

[0025] 0.208g nickel acetate [Ni(CH 3 COO) 2 4H 2 O] was dissolved in 23mL neutral deionized water to obtain a solution with a nickel acetate concentration of 0.836mmol / L, which was dissolved at room temperature and fully stirred to form a solution containing Ni(CH 3 COO) 2 mixed aqueous solution;

[0026] To Ni(CH 3 COO) 2 Add 1.0mL glycerol to the mixed aqueous solution, so that the volume ratio of deionized water to glycerol is 23:1, after stirring at room temperature for 10min, place the mixed system on a stainless steel React in a reaction kettle for 3.5 hours at 200°C;

[0027] After the obtained suspension was cooled to room temperature, it was centrifuged in a refrigerated centrifuge at a speed of 6000r / min for 10 minutes, then washed with distilled w...

Embodiment 2

[0031] A method for preparing a camellia-shaped nickel-based catalyst for treating alkaline dyeing and finishing wastewater, comprising the steps of:

[0032] S1, camellia-like β-Ni(OH) 2 Precursor preparation:

[0033] 0.208g nickel acetate [Ni(CH 3 COO) 2 4H 2 O] was dissolved in 23mL neutral deionized water to obtain a solution with a nickel acetate concentration of 0.836mmol / L, which was dissolved at room temperature and fully stirred to form a solution containing Ni(CH 3 COO) 2 mixed aqueous solution;

[0034] To Ni(CH 3 COO) 2 Add 1.0mL glycerol to the mixed aqueous solution, so that the volume ratio of deionized water to glycerol is 23:1, after stirring at room temperature for 10min, place the mixed system on a stainless steel React in a reaction kettle for 3.5 hours at 200°C;

[0035] After the obtained suspension was cooled to room temperature, it was centrifuged in a refrigerated centrifuge at a speed of 6000r / min for 10 minutes, then washed with distilled w...

Embodiment 3

[0039] A method for preparing a camellia-shaped nickel-based catalyst for treating alkaline dyeing and finishing wastewater, comprising the steps of:

[0040] S1, camellia-like β-Ni(OH) 2 Precursor preparation:

[0041] 0.208g nickel acetate [Ni(CH 3 COO) 2 4H 2 O] was dissolved in 23mL neutral deionized water to obtain a solution with a nickel acetate concentration of 0.836mmol / L, which was dissolved at room temperature and fully stirred to form a solution containing Ni(CH 3 COO) 2 mixed aqueous solution;

[0042] To Ni(CH 3 COO)2 Add 1.0mL glycerol to the mixed aqueous solution, so that the volume ratio of deionized water to glycerol is 23:1, after stirring at room temperature for 10min, place the mixed system on a stainless steel React in a reaction kettle for 3.5 hours at 200°C;

[0043] After the obtained suspension was cooled to room temperature, it was centrifuged in a refrigerated centrifuge at a speed of 6000r / min for 10 minutes, then washed with distilled wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com