Coal slime flotation method with MEA pregnant solution as flotation agent

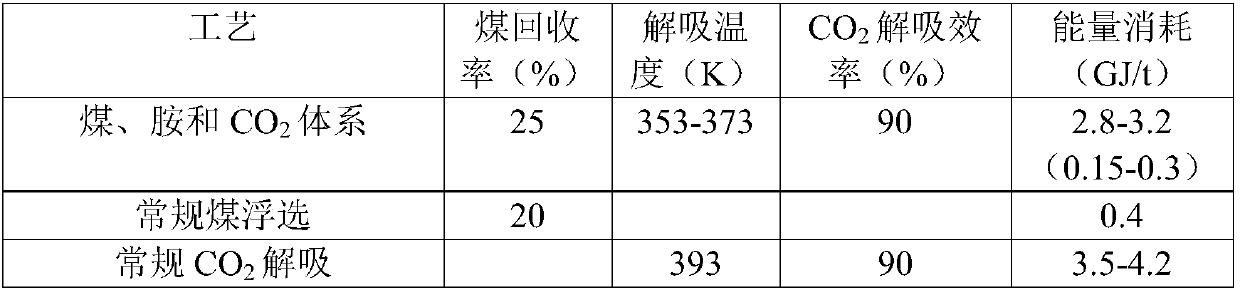

A coal slime flotation and flotation agent technology, which is applied in flotation, separation methods, chemical instruments and methods, etc., can solve the problems of large amount of flotation agents, low selectivity of fine-grained coal, complicated process, etc., and achieve improvement Flotation effect, energy consumption reduction, parameter optimization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

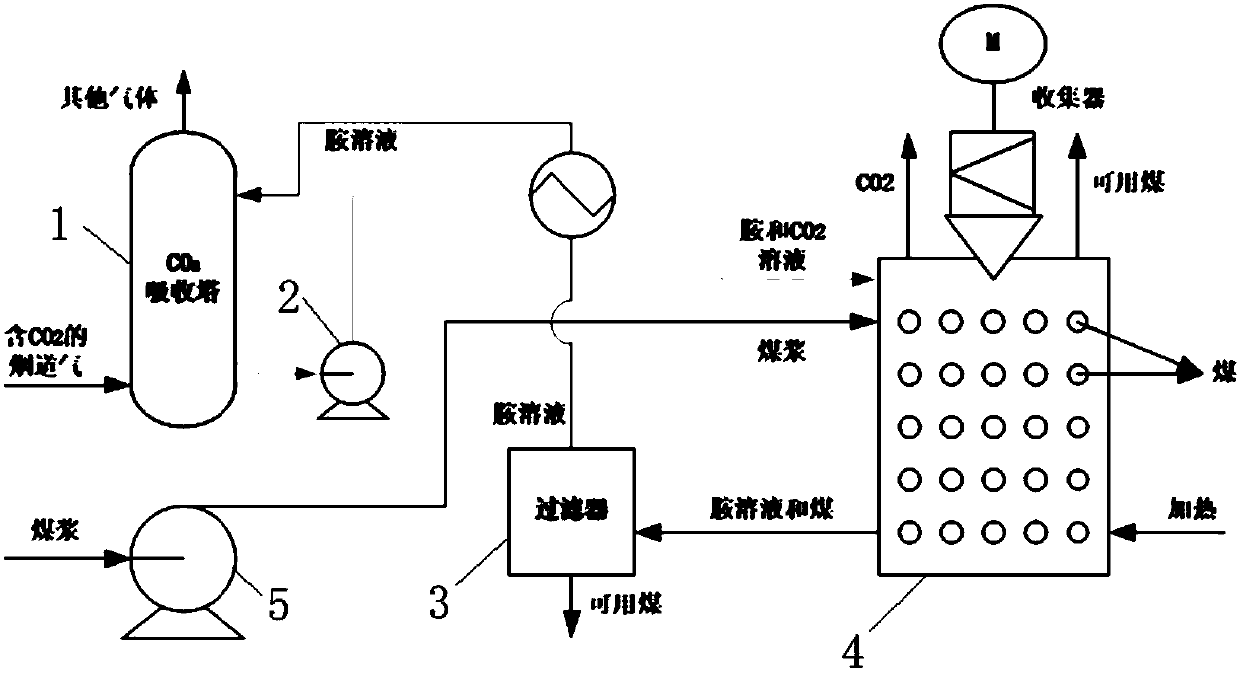

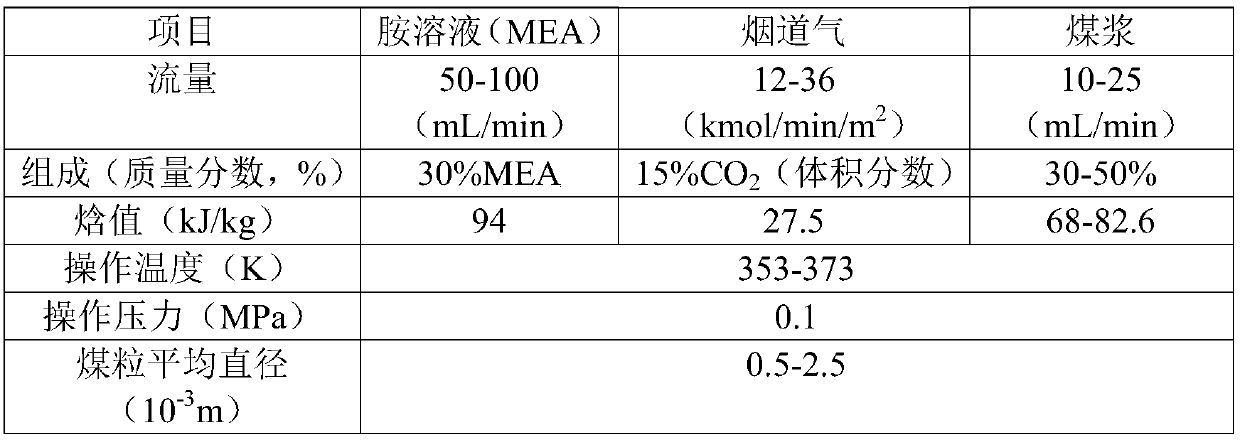

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] In order to overcome the traditional amine absorption method at the same time, the present invention: 1. The problem of high natural loss of the capture liquid due to the easy evaporation of the amine solution; 2. CO 2 The problem of high energy consumption in the desorption process. And in the traditional coal flotation method, the process is complicated, the amount of hydrocarbon oil collector is large, and the selectivity to low-quality coal is low. A coal slime flotation method using MEA rich liquid as a flotation agent is provided.

[0021] The present invention adopts the device of following structure, and this device comprises absorption tower 1, first pump 2, second pump 5, filter 3 and stripper 4, wherein, absorption tower 1 links to each other with stripper 4 through first pump 2 , the second pump 5 is connected with the stripper 4, and the stripper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com