A Gemini Surfactant for Mineral Flotation

A Gemini surface and mineral flotation technology, applied in flotation, solid separation, etc., to achieve good biodegradability, increase hydrophobicity, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

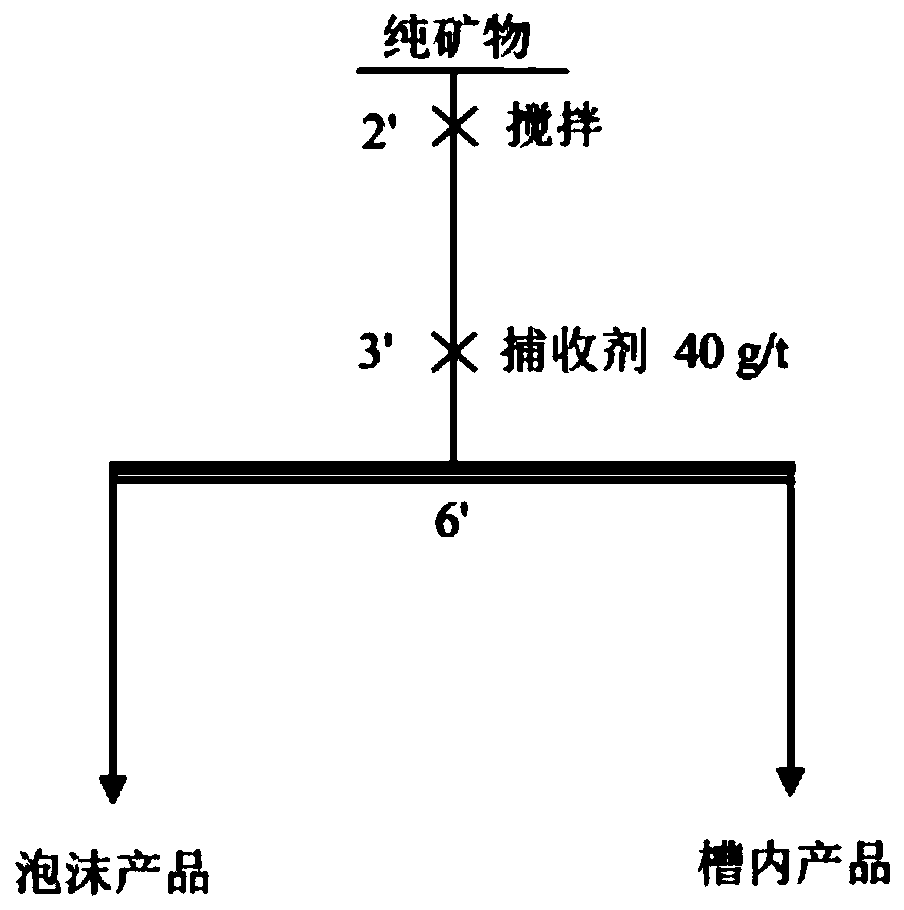

[0029] Embodiment 1: the application of gemini surfactant in flotation potassium chloride pure mineral

[0030] Put 2.0g of potassium chloride pure mineral with a particle size of -0.15mm~+0.074mm in a 40mL flotation tank, add 30mL of saturated potassium chloride solution, stir for 2 minutes to make it evenly mixed, and the amount of collector is 40g / t Flotation is carried out under certain conditions, and the flotation process flow chart is shown in figure 1 . Table 1 shows the flotation contrast test results of two kinds of Gemini collectors among the present invention and two kinds of collectors cetylamine and octadecylamine commonly used. It can be seen from Table 1 that the collection ability of Gemini collector to potassium chloride is obviously stronger than that of two commonly used aliphatic amine collectors.

[0031] Table 1 Comparative experimental results of collector flotation pure minerals

[0032]

Embodiment 2

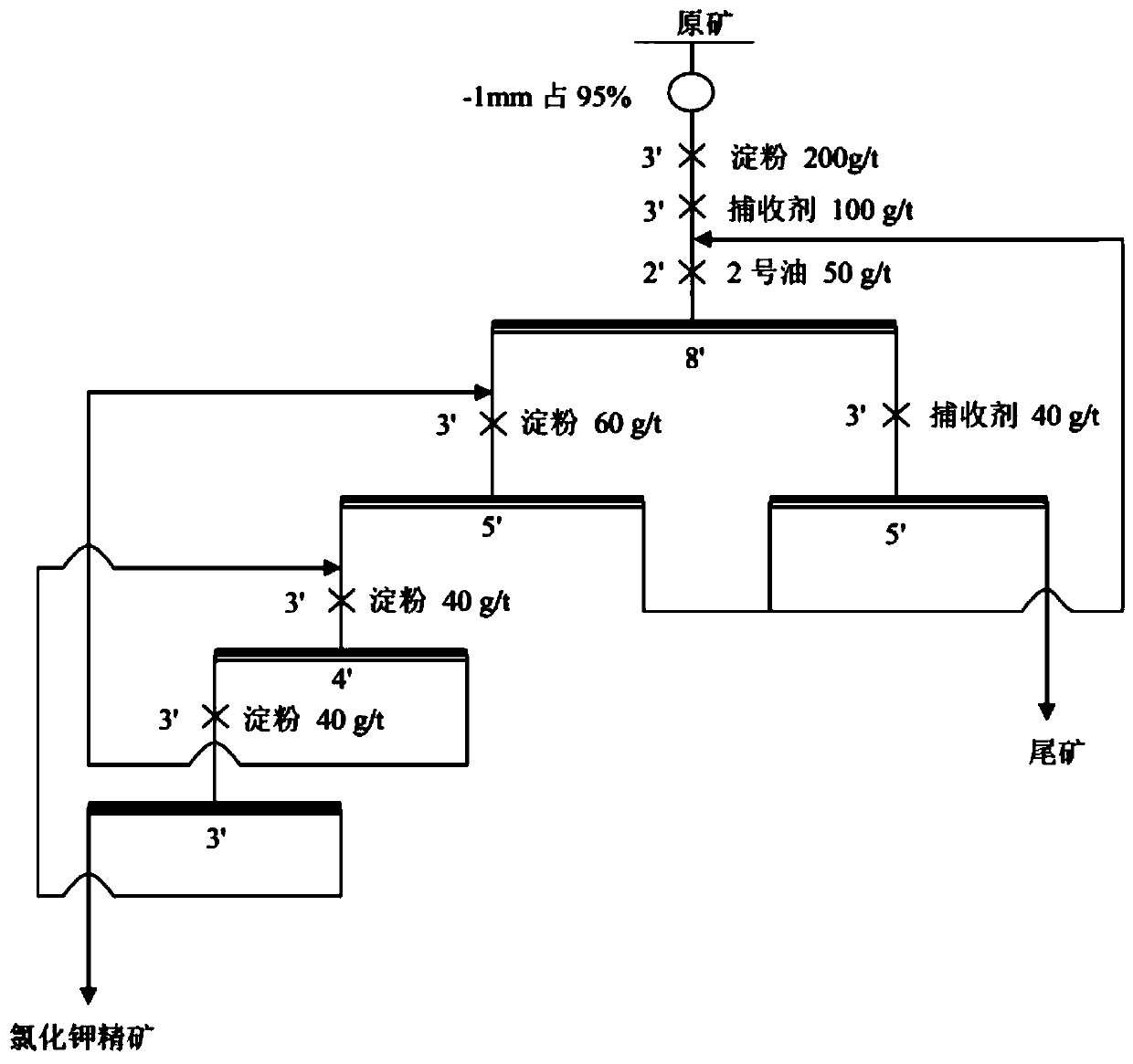

[0033] Example 2: Application of dibromide-bis[3-(N,N-dimethyloctadecylammonium) propane]-malonamide in flotation of potash salt ore

[0034]A potash mine sample in Qinghai, the original ore contains KCl 9.56%, NaCl 51.93%, adding saturated brine to grind the ore to -1mm to account for 95%, flotation pulp concentration 25%, starch dosage 200g / t, collector dosage Under the conditions of 100g / t and 50g / t of foaming agent No. 2 oil, carry out roughing flotation of potassium salt ore, add collector 40g / t for sweeping, add 60g / t of starch for the first selection, and add 60g / t of starch for the second selection The amount of starch added is 40g / t, and the amount of starch added for three times of selection is 40g / t. The flow chart of the flotation process is shown in figure 2 . Gemini surfactant dibromide-bis[3-(N,N-dimethyloctadecylammonium) propane]-malonamide in the present invention and the flotation comparison of commonly used collector octadecylamine The test results are s...

Embodiment 3

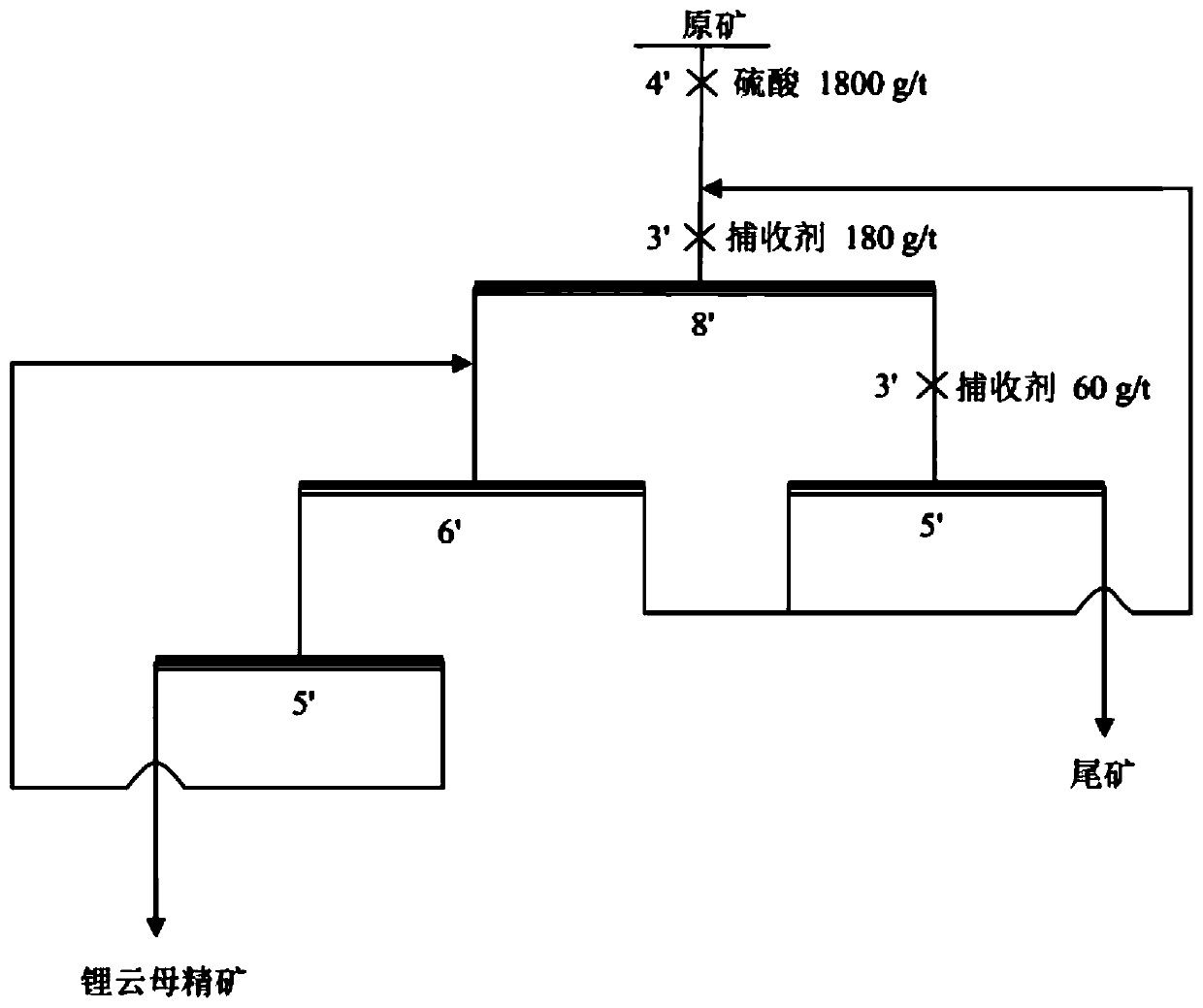

[0038] Example 3: Application of dichloride-bis[3-(N,N-dimethyldodecylammonium) propane]-malonamide in lepidolite ore flotation

[0039] The main useful mineral of the gravity separation tailings of a tantalum-niobium mine is lepidolite, which contains Li 2 O 0.86%, the particle size is -0.074mm, accounting for 30%, add water to adjust the slurry to a mass concentration of 30%, add 1800g / t sulfuric acid, 180g / t dichloride-bis[3-(N,N-dimethyl dodeca Alkyl ammonium) propane] - malonamide, carry out roughing flotation of lepidolite ore, sweep and add 60g / t dichloride-bis[3-(N,N-dimethyldodecyl ammonium) propane] - Malonamide, using a flotation process of one roughing, one sweeping, and two fine selections, the flotation process flow chart is shown in image 3 . Gemini surfactant dichloride-bis[3-(N,N-dimethyldodecyl ammonium) propane]-malonamide in the present invention and the flotation contrast of commonly used collector dodecylamine The test results are shown in Table 3. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com