Aluminum bronze ingot mould ingot casting device

An aluminum bronze and ingot mold technology, applied in the field of aluminum bronze casting, can solve problems such as easy aggregation and slagging, lower ingot quality, discontinuous metal solidification, etc., and achieve the effect of avoiding quality reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

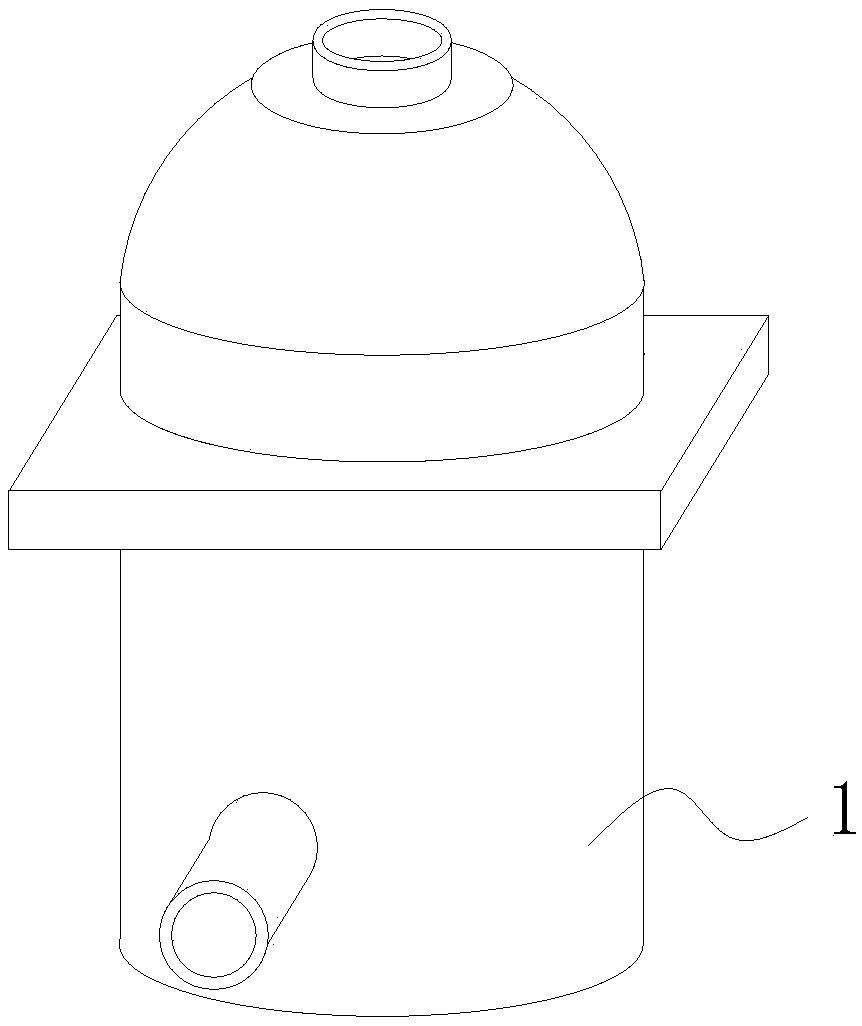

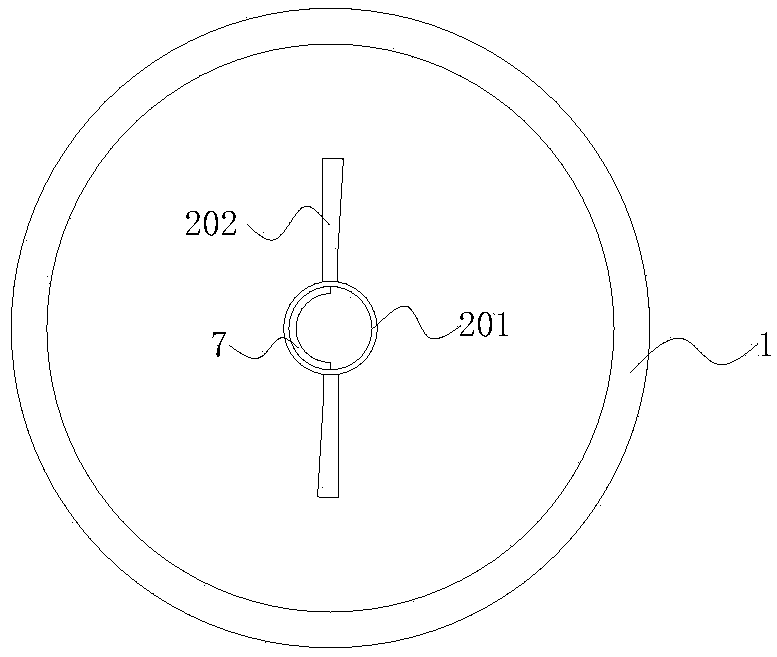

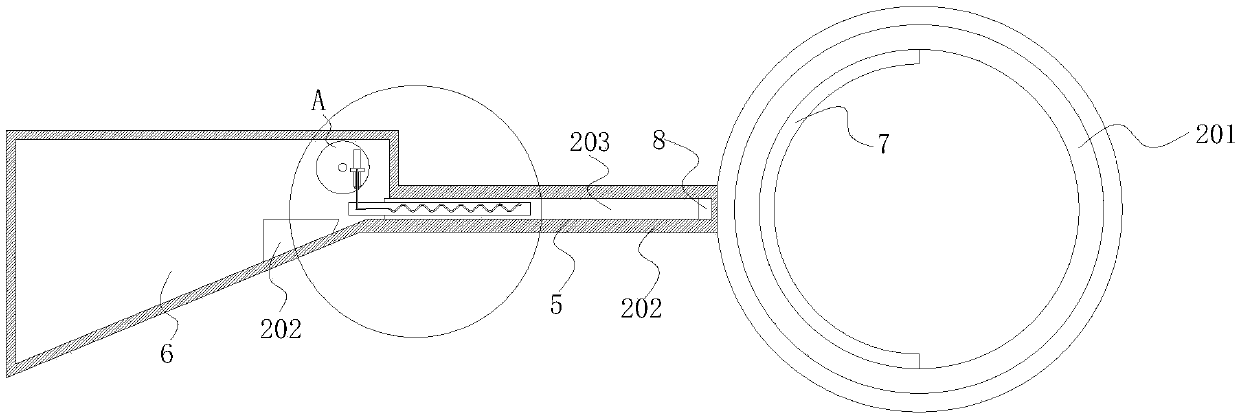

[0028] Such as Figure 1-8 As shown, the embodiment of the present invention provides an aluminum bronze ingot mold ingot casting device, which includes a furnace body 1 provided with an electromagnetic stirrer, an alumina catcher 2 is arranged in the inner cavity of the furnace body 1, and the furnace body A magnet 3 is inlaid on the inner wall of the furnace body 1, and the alumina catcher 2 includes a barrel body 201 fixedly installed at the bottom of the inner wall of the furnace body 1, and a rotatable alumina collecting plate is arranged on the side wall of the barrel body 201 through a bearing 202, the front of the alumina collecting plate 202 includes a vertical surface in the same plane as the diameter of the whole body 1 and an inclined surface inclined to the vertical surface, and the angle between the inclined surface and the vertical surface is an obtuse angle, The interior of the alumina collection plate 202 is hollow, and the interior of the alumina collection p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com