Preparation method of Co3O4/graphite felt composite electrode applied to anodic oxidation system

A composite electrode and anodic oxidation technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problems of herbicide biological toxicity, etc., achieve enhanced oxidation efficiency, good conductivity, and improved oxidation The effect of potency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

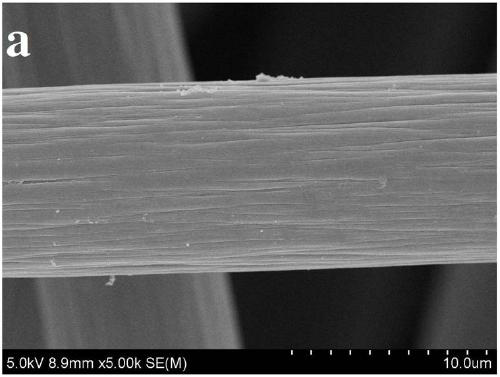

[0021] (1) Put a 1cm×7cm graphite felt into an isopropanol solution and ultrasonically clean it to remove dirt, then rinse off the residual isopropanol with ultrapure water, and dry it with nitrogen to obtain an unloaded graphite felt;

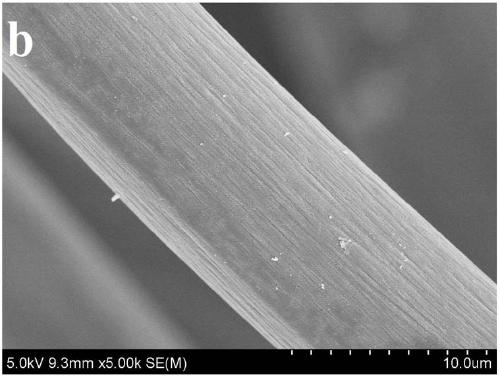

[0022] (2) Take cobalt acetate tetrahydrate and add it to the ethanol solution, stir and dissolve it fully and use it as soaking liquid, the concentration of cobalt acetate tetrahydrate is 4mmol / L. The graphite felt cleaned in step (1) was immersed in an ethanol solution of cobalt acetate tetrahydrate and sonicated for 30 minutes, and then placed in a petri dish at room temperature to dry overnight.

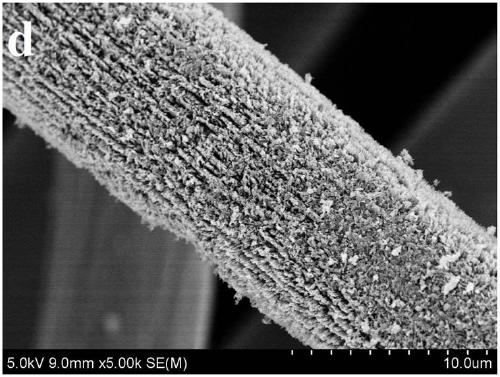

[0023] (3) Place the dried graphite felt in an atmosphere furnace, and calcinate at 300°C for 60 minutes (the room temperature rises to 300°C, the heating rate is 5°C / min), and the air is pressed into the furnace at a flow rate of 1L / min during the calcining , get Co 3 o 4 Load graphite felt for spare;

[0024] (4) Co prepared in step (3) 3 o...

Embodiment 2

[0027] (1) Put a 1cm×7cm graphite felt into an isopropanol solution and ultrasonically clean it to remove dirt, then rinse off the residual isopropanol with ultrapure water, and dry it with nitrogen to obtain an unloaded graphite felt;

[0028] (2) Take cobalt acetate tetrahydrate and add it to the ethanol solution, stir and dissolve it fully and use it as soaking liquid, the concentration of cobalt acetate tetrahydrate is 4mmol / L. The graphite felt cleaned in step (1) was immersed in an ethanol solution of cobalt acetate tetrahydrate and sonicated for 30 minutes, and then placed in a petri dish at room temperature to dry overnight.

[0029] (3) Place the dried graphite felt in an atmosphere furnace, and calcinate at 300°C for 60 minutes (the room temperature rises to 300°C, the heating rate is 5°C / min), and the air is pressed into the furnace at a flow rate of 1L / min during the calcining , get Co 3 o 4 Load graphite felt for spare;

[0030] (4) Co prepared in step (3) 3 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com